Vertical treatment equipment for high-concentration ammonia nitrogen wastewater

A technology of ammonia nitrogen wastewater and treatment equipment, applied in water/sewage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of reducing the capacity of the reaction tank, reducing the floor space, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with specific embodiments.

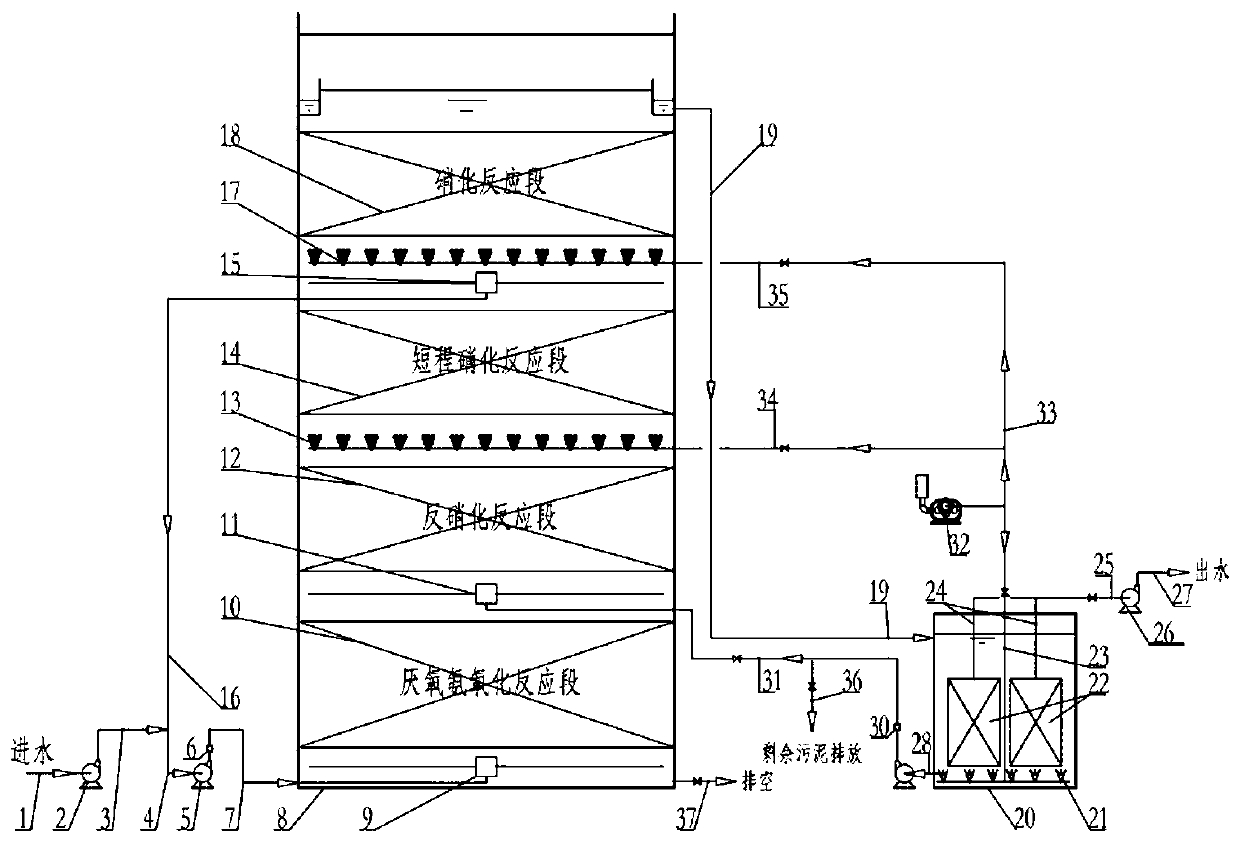

[0017] see figure 1 , is a vertical high-concentration ammonia-nitrogen wastewater treatment equipment, including a vertical reaction tank 8, and the anaerobic ammonium oxidation reaction section, denitrification reaction section, and short-range nitrification reaction are sequentially arranged in the vertical reaction tank 8 from bottom to top. Section, nitrification reaction section, water inlet pump 2, one end is communicated with described inlet pump 2 and the other end is communicated with the bottom of described vertical reaction tank 8 short-range nitrification liquid reflux pump 5, and described anaerobic ammonium oxidation reaction section includes being arranged on The bottom uniform water distribution device 9 at the bottom of the vertical reaction tank 8, the anaerobic ammonium oxidation filler 10 arranged on the bottom uniform water distribution device 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com