Detachable thermosetting epoxy adhesive composition and preparation method thereof

A technology of epoxy adhesives and compositions, applied in the direction of adhesives, epoxy resin adhesives, adhesive types, etc., can solve problems such as poor acid resistance, wear resistance and decreased adhesion, general acid and alkali resistance of organic silicon, etc. Achieve excellent surface dryness and reduce pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

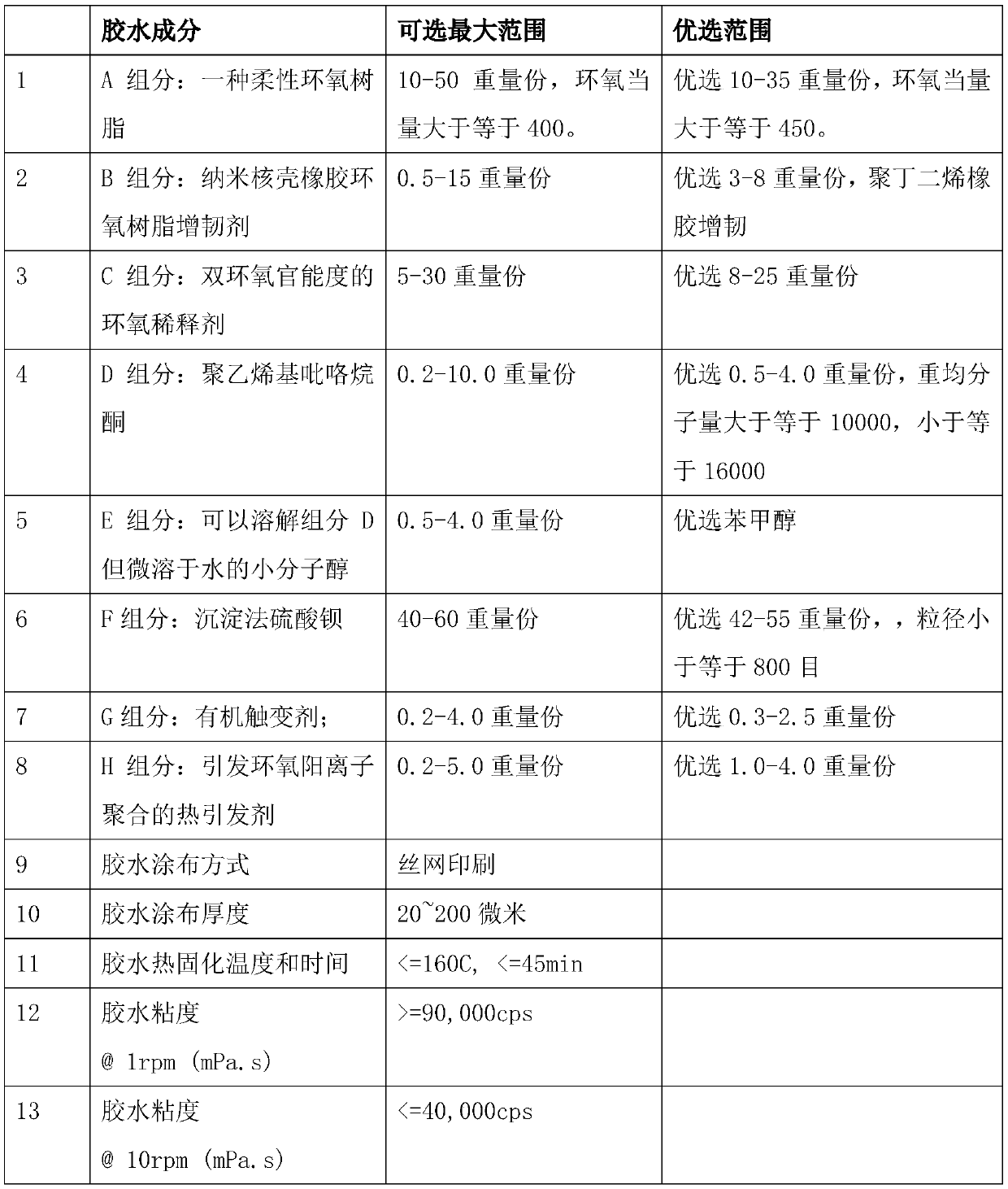

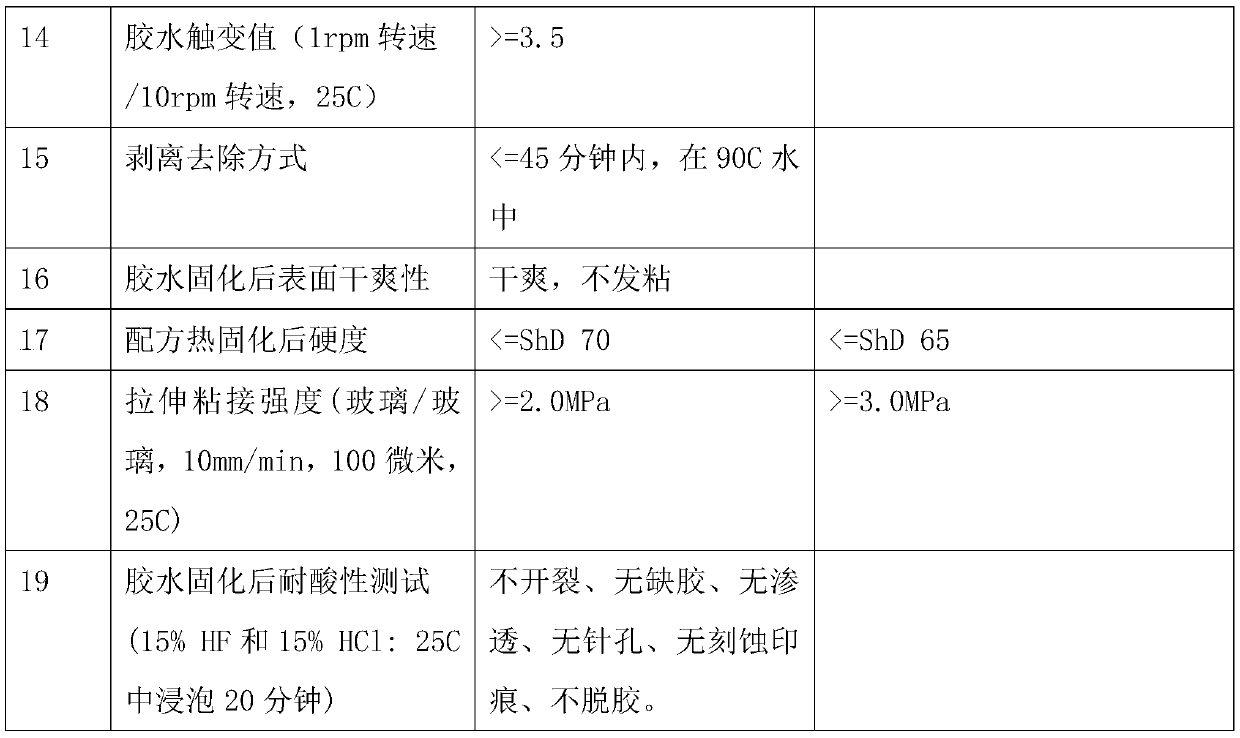

[0038] The adhesive composition is formulated according to the following table formulation:

[0039]

[0040]

[0041] All parts are parts by weight, based on 100 parts by weight of the adhesive composition.

[0042] Specific preparation method:

[0043] S1, dissolving component D in component E, the mass concentration is 30%, to make premix;

[0044] S2, above-mentioned premix, A-C, F-H components (total 100g) are added successively in the plastic bucket that capacity is 150g, put into mixer, under 2500 rev / min, high-speed dispersion is mixed 10 minutes;

[0045] Wherein, the model of the mixer is SpeedMixer DAC 150.1FVZ.

[0046] Once prepared, test and verify it:

[0047] 1. Viscosity and Thixotropic Value Test

[0048] Refers to Brookfield viscosity (Brookfield), the test adopts ASTM D1084, and the test temperature is 25°C. The thixotropic value of the glue is obtained according to the ratio of the viscosity at 1 rpm and the viscosity at 10 rpm (25C);

[0049] 2....

Embodiment 2

[0072] In the same manner as in Example 1, the adhesive composition of Example 2 was prepared. The formulation of the adhesive composition is shown in the following table, in Example 2, the water-soluble polymer is removed, and the polymer PVP K 30 is used:

[0073]

[0074]

[0075] All parts are parts by weight, based on 99.25 parts by weight of the adhesive composition with PVP K 30 removed.

[0076] The viscosity of the obtained adhesive composition was 136,700cps / 25°C (rotational speed 1 rpm); 30,800cp / 25°C (rotational speed 10rpm);

[0077] Glue Thixotropic Index: 4.44

[0078] Screen printing test: good, no stringing or edge smearing

[0079] Glue heat curing conditions: 150C, 30 minutes.

[0080] Acid resistance test after glue curing: passed.

[0081] Surface dryness and peeling removal method after the glue is cured:

[0082] -23C / 50%RH relative humidity, surface dryness: excellent, not sticky.

[0083] - But the glass sample after screen printing 50 micr...

Embodiment 3

[0086] In the same manner as in Example 1, the adhesive composition of Example 3 was prepared. The formulation of the adhesive composition shown in the following table, Example 3 greatly reduces the amount of barium sulfate:

[0087]

[0088]

[0089] All parts are parts by weight, based on 100 parts by weight of the adhesive composition.

[0090] The viscosity of the obtained adhesive composition was 96,500cps / 25°C (rotational speed 1 rpm); 27,900cp / 25°C (rotational speed 10rpm);

[0091] Glue Thixotropic Index: 3.46

[0092] Screen printing test: poor, with obvious wire drawing or edge tailing.

[0093] It can be clearly seen that compared with the adhesive composition of Comparative Example 1, the thixotropy of the glue is significantly reduced due to the greatly reduced use amount of barium sulfate. Since barium sulfate is chemically inert, its addition can significantly reduce the crosslink density and polarity of the adhesive. When the amount of calcium sulfate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thixotropic index | aaaaa | aaaaa |

| thixotropic index | aaaaa | aaaaa |

| thixotropic index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com