Compound active black dye applicable to deep printing of rayon and clean production process thereof

A technology of reactive black and dyes, applied in the field of dyes, can solve the problems of high printing cost, hard hand feeling, and large three waste pollution of rayon in deep black printing, and achieve good controllability of printing shade, good dyeing lifting power, and reduction of three wastes The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

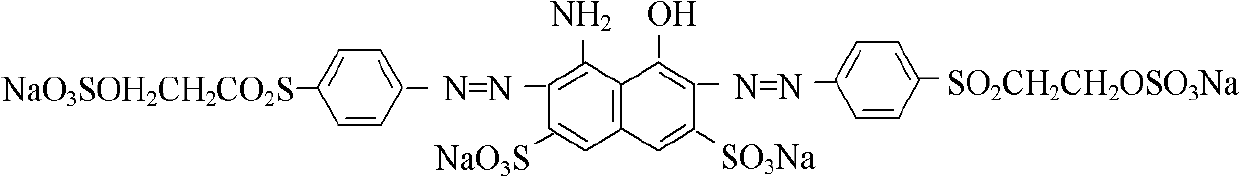

[0020] Example 1, the diazonium salt prepared by diazotizing the para-ester with hydrochloric acid, then coupled with H acid under strong acidic conditions of PH<2, and then coupled under the conditions of PH4.5~7.5 , the coupling temperature is 5-12° C., and the molar ratio of H acid to para-ester is 0.485:1.0 to obtain the structural component of formula I; this component can also be prepared according to conventional methods. (C.I. Reactive Black 5).

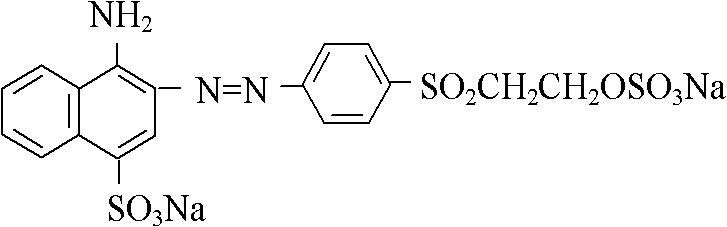

[0021] The diazonium salt prepared by diazotizing the p-position ester with hydrochloric acid, the diazonium reaction temperature is 0-10°C, and then adding 1-naphthylamine-4 sulfonic acid sodium salt at pH 5.5-7.0, temperature 5-12 Coupling is carried out under the condition of ℃, and the dye of the structural component of the formula II is obtained; (reactive red).

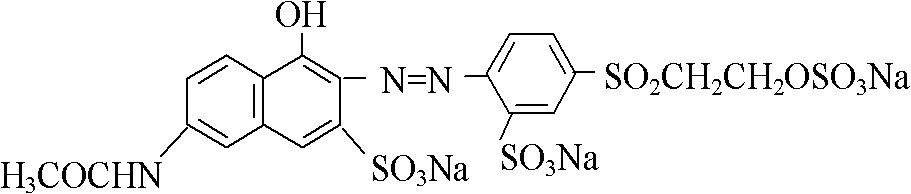

[0022] The diazonium salt prepared by diazotizing the sulfonated para-ester with hydrochloric acid, the diazonium reaction temperature is 0-10°C, and then add...

Embodiment 2

[0024] Embodiment 2, will make reactive black, reactive red and reactive orange dyestuff according to the method for embodiment 1 and be 70 parts of C.I. reactive black 5, 15 parts of reactive red, 15 parts of reactive orange solution mix according to the mass proportion after drying, spray Dried to obtain reactive black raw powder dyes, adding standardized auxiliary agents to obtain commercial products.

Embodiment 3

[0025] Embodiment 3, will make reactive black, reactive red and reactive orange dyestuff according to the method for embodiment 1 and be 65 parts of C.I. reactive black 5, 25 parts of reactive red, 25 parts of reactive orange solution mix according to the mass proportion after drying, spray Dried to obtain reactive black raw powder dyes, adding standardized auxiliary agents to obtain commercial products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com