Moisture absorption coating for single plastic film label, label and preparation method of label

A plastic film and coating technology, applied in the field of labels, can solve the problems of high cost of the adhesive layer of the primer, affect the use of secondary bottle labeling, and low output rate, meet the printing process and innovation requirements, and be suitable for high-speed automatic labeling The effect of standard and good moisture-proof and water-resistant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

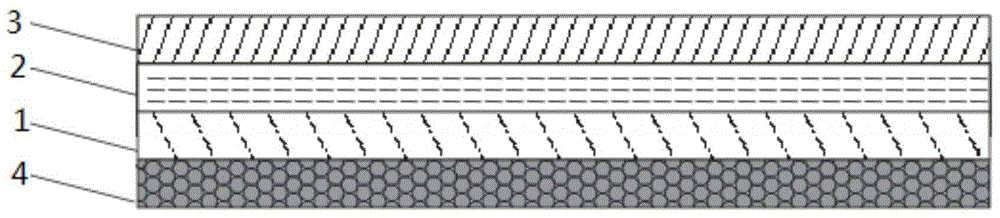

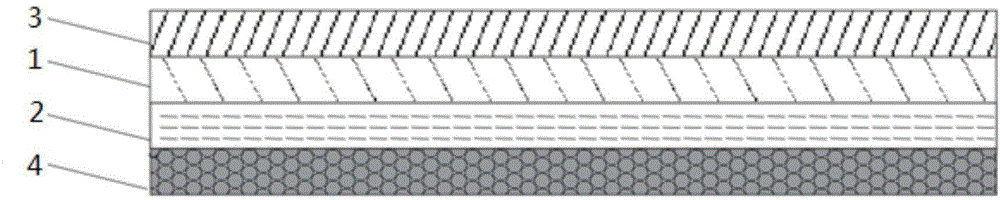

[0057] The method for preparing the above-mentioned single plastic film label provided by the present invention comprises steps:

[0058] Preparation of a single plastic film layer 1;

[0059] Printing layer 2 preparation;

[0060] Preparation of antistatic polymer coating 3;

[0061] Hygroscopic coating 4 preparation.

[0062] For the single-sheet plastic film label in Scheme 1, the printing layer 2 can be prepared first, the antistatic coating 3 is coated on the printing layer 2, and then the bracket is turned over to coat the hygroscopic coating 4 on the other side of the film layer. which is,

[0063] The first step: the preparation of a single plastic film layer 1; corona treatment is performed on the plastic film substrate with a thickness of 20-100 μm, so that the surface tension reaches the adhesion requirement required by the printing process;

[0064] The second step: preparation of the printing layer 2, placing the single plastic film layer 1 on the film support...

Embodiment 1

[0078] 1. Preparation of hygroscopic coating: add 12 parts of PVA, 70 parts of grafted starch, 6 parts of caseinic acid, 10 parts of acrylic acid (the softening point of the acrylic resin should be controlled below 50°C), 2 parts of sodium polyacrylate, and then add an appropriate amount of Ethanol and water, wherein the volume ratio of ethanol and water is 1:1, so that the solid content of the obtained mixture is 30%. After mixing, stir at 500 rpm for 30 minutes, and mix evenly to obtain a hygroscopic coating.

[0079] 2. Preparation of anti-static polymer coating: Add 59 parts of hydroxyacrylic acid water-based emulsion, 40 parts of hydroxy water-based styrene, and 1 part of conductive transparent graphite powder in sequence, and stir for 40 minutes at 650 rpm to mix evenly That is, an antistatic polymer coating is obtained.

[0080] 3. The implementation steps of preparing a single plastic film label are:

[0081] 1) Corona treatment is performed on the straw-modified plas...

Embodiment 2

[0087] 1. Preparation of hygroscopic coating: add 18 parts of PVA, 53.99 parts of grafted starch, 8 parts of caseinic acid, 20 parts of acrylic acid (the softening point of acrylic resin should be controlled below 50°C), 0.01 part of sodium polyacrylate, and then add an appropriate amount of Ethanol and water, wherein the volume ratio of ethanol and water is 1:1, so that the solid content of the obtained mixture is 60%, under the condition of 800 rpm, stir for 40 minutes, and mix evenly to obtain a hygroscopic coating.

[0088] 2. Preparation of anti-static polymer coating: Add 40 parts of hydroxyacrylic acid water-based emulsion, 50 parts of hydroxy water-based styrene, and 10 parts of conductive transparent graphite powder in sequence, stir for 50 minutes at 500 rpm, and mix evenly to obtain Antistatic polymer coating.

[0089] 3. The implementation steps of preparing a single plastic film label are:

[0090] 1) Corona treatment is performed on the straw-modified plastic fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com