Method for improving strength of reinforcing steel bar

A technology for reinforcing steel and strength, applied in the field of improving the strength of steel bars, can solve the problems of increasing the manufacturing cost of steel bars, and achieve the effects of increasing strength and improving hardenability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The specific operation steps are as follows:

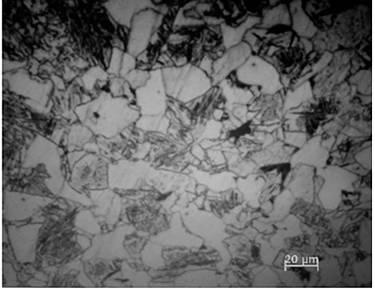

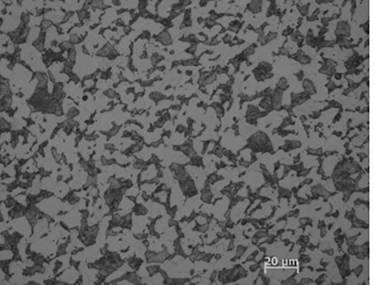

[0026] 1) The lining of a 40-ton induction furnace is manufactured by adding boric acid to silica. The refractoriness of silica is 1800°C, and the water absorption rate is 2.3%. In terms of mass percentage, its specific composition is shown in Table 1, and the particle size ratio of silica sand is listed in Table 2. Boric acid The sand material particle size ratio is shown in Table 3. Boric acid and silica sand are mixed uniformly by a drum machine, and water is added during the mixing. The amount of water added is 1.2% of the weight of the total sand.

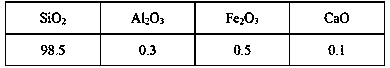

[0027] Table 1 Chemical composition of silica, %

[0028]

[0029] Table 2 The particle size range of silica sand

[0030]

[0031] Table 3 The particle size range of boric acid sand material

[0032]

[0033] 2) The furnace lining is formed by masonry method. Before forming, the furnace lining material is baked at 320°C for 6 hours. After forming, it is sintere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com