Automatic layered water taking system

A layered water intake and water intake tower technology, applied in water conservancy projects, artificial waterways, hydroelectric power generation, etc., can solve problems such as irrigation, adverse effects of aquatic organisms, complex operation of steel structure stacking doors, and influence of water temperature distribution in downstream river sections. Achieve the effects of strong functional scalability, reduced steel consumption, and reduced investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

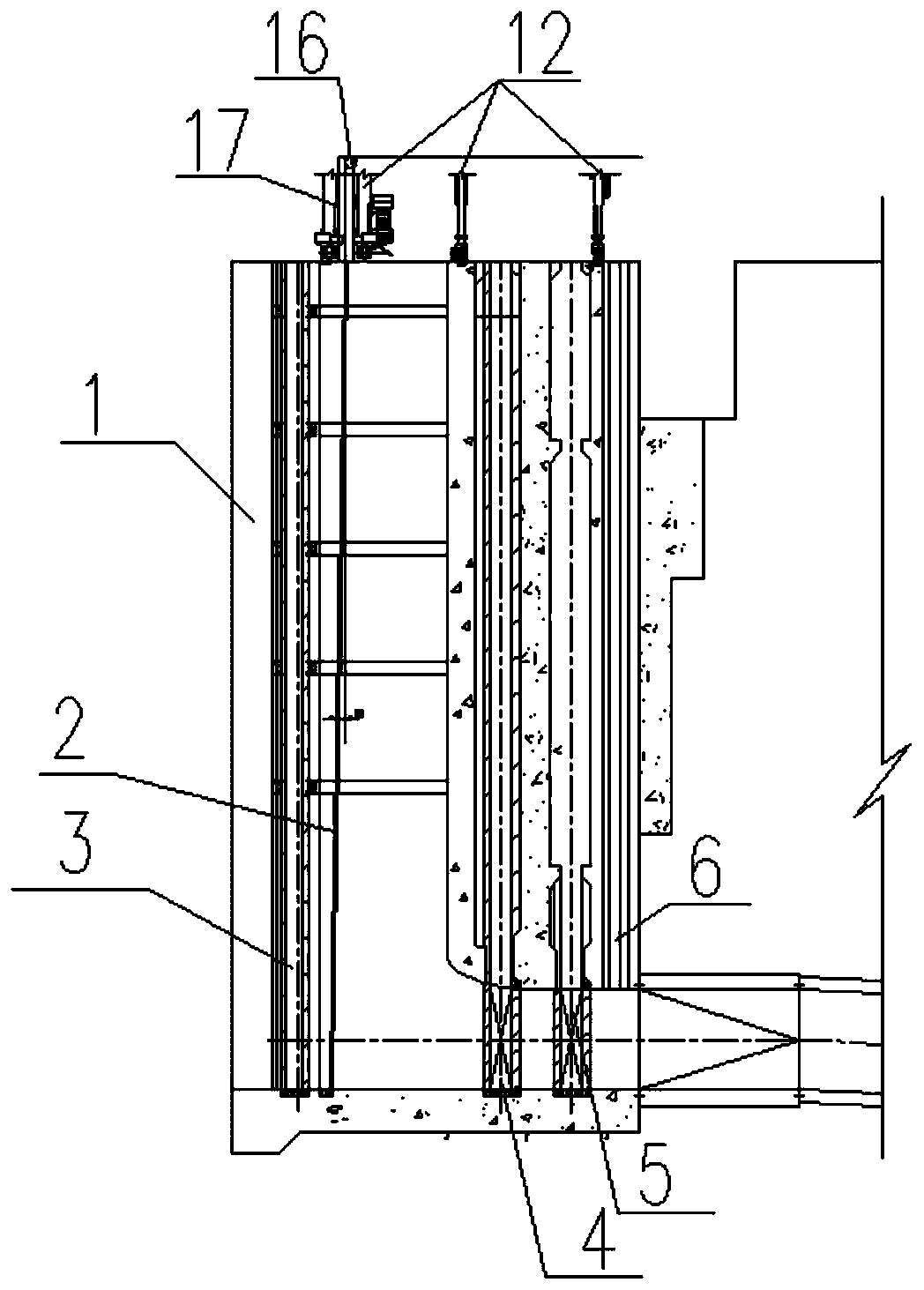

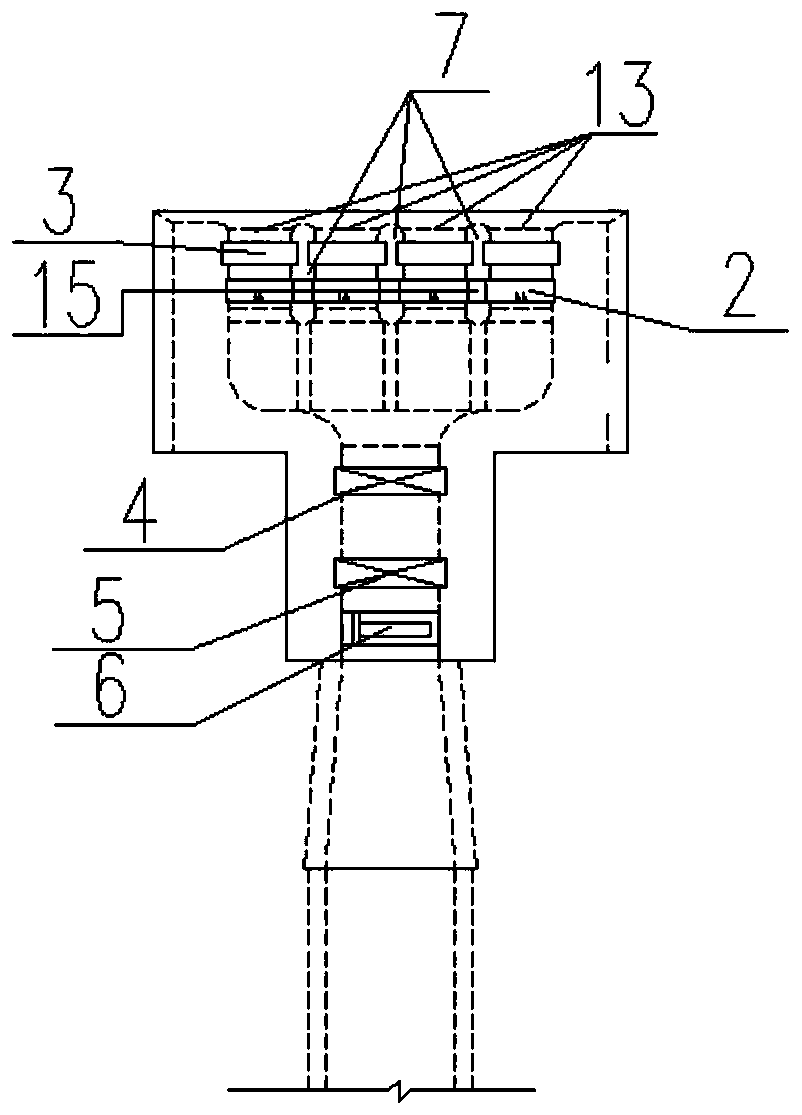

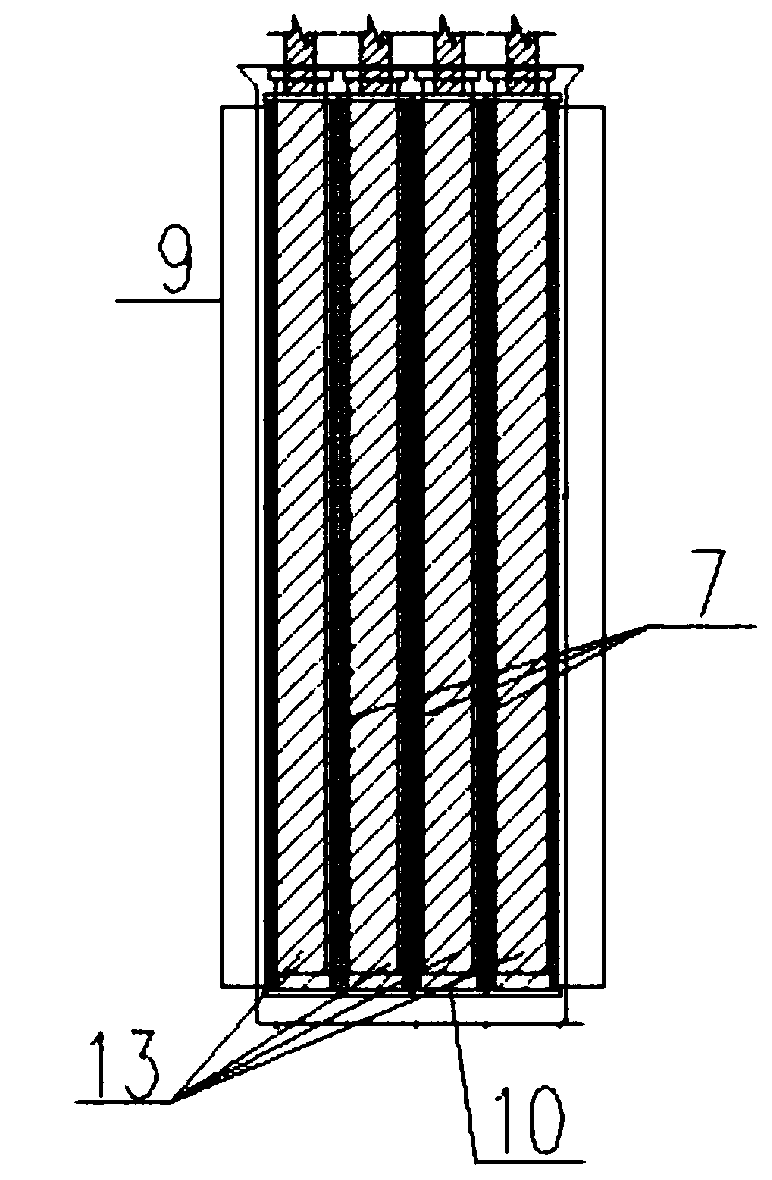

[0024] Such as Figure 1 to Figure 5 As shown, the present invention provides an automatic layered water intake system, which includes a rolling curtain 2, a water-permeable hanging cloth 11 and a water intake tower 1 deployed in the water flow channel. The water intake tower 1 faces the upstream side of the water flow. The water surface, the opposite side is the back water surface, the back water surface is connected with a curtain wall, the bottom of the curtain wall is equipped with an electromagnetic strip 10, the length direction of the electromagnetic strip 10 is the same as the width direction of the water flow channel, and a winch 12 is installed on the top of the curtain wall. One side of the hanging cloth 11 is wound on the outer peripheral surface of the reel, the other side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com