Adjacent continuous tunnel group ventilation experiment device and manufacture method

A test device and tunnel group technology, which is applied in mine/tunnel ventilation, earthwork drilling, mining equipment, etc., can solve problems such as difficulty in evaluating the impact of ventilation and sewage, and achieve shortened production cycles, reduced test costs, and thermal stability. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

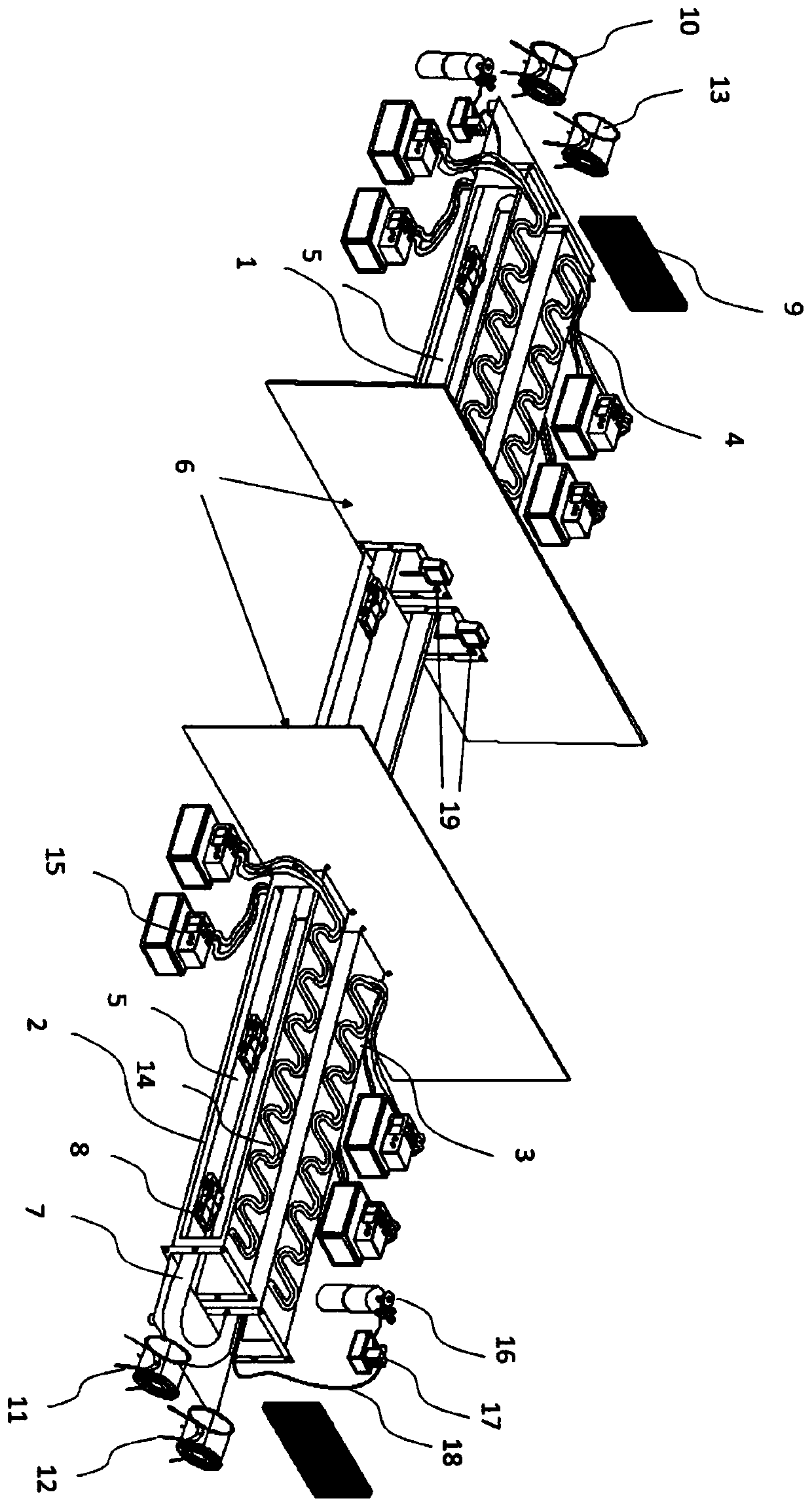

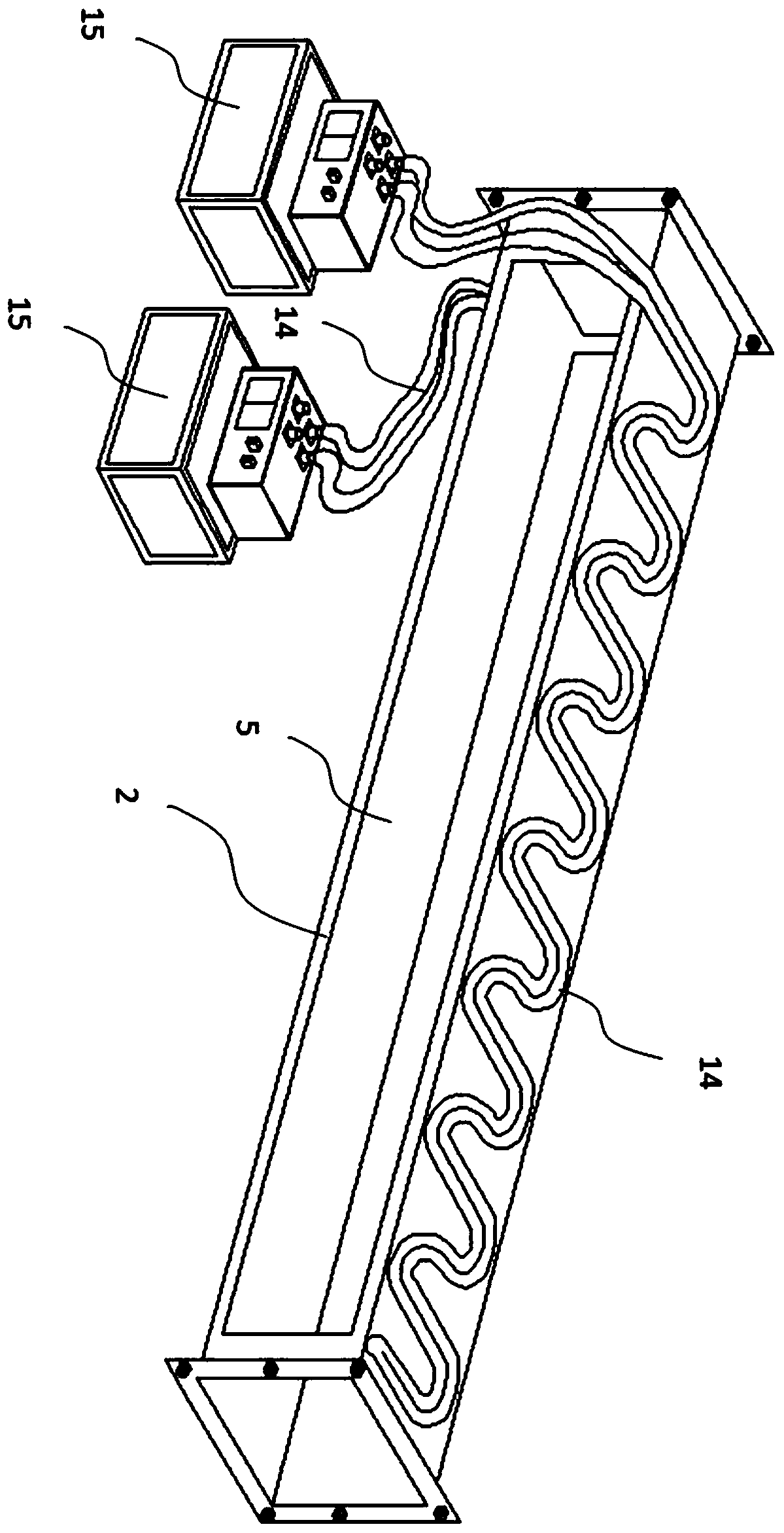

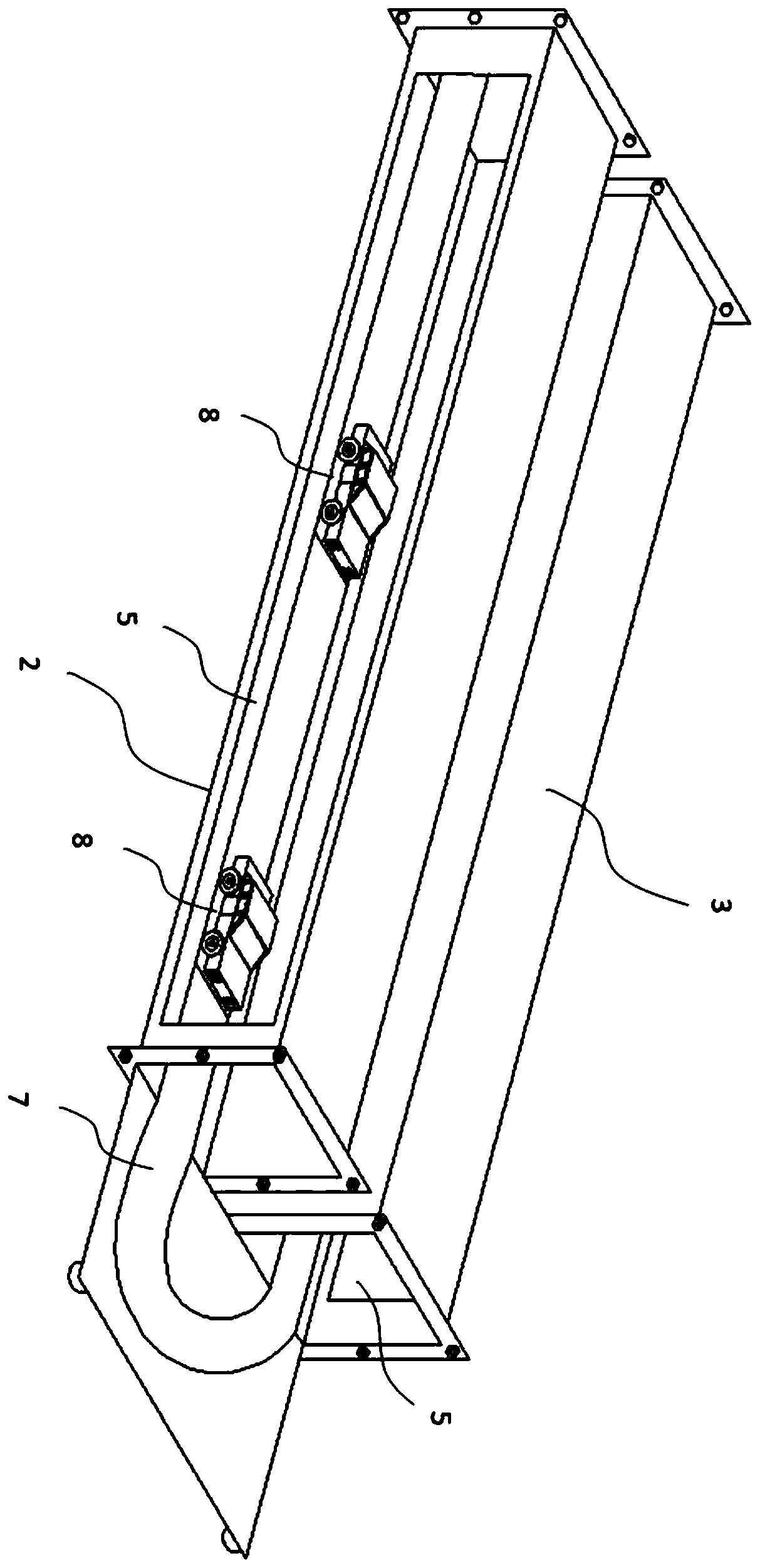

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] According to the principle of similarity and the results of a large number of tunnel ventilation tests, in order to ensure that the test has a clear physical meaning, the test device must not only be geometrically similar to the actual tunnel, but also satisfy dynamic similarity, that is, similar flow resistance. To achieve similar flow resistance between the test device and the actual tunnel, the air resistance coefficients of the two must be equal, and the air flow of the two enters the self-modeling area. When considering the influence of the temperature difference between the tunnel body and the environment, the Froude coefficient that affects the thermal buoyancy effect needs to be included in the calculation range. The jet diffusion close to the openings of the tunnel group belongs to the three-dimensional wall jet. A lar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com