An automatic quantitative oil injection control system and control method for shock absorbers

A control system and shock absorber technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of oil temperature control, production stop loss, and oil quality precise control, etc., to avoid The effect of stopping production loss, ensuring normal production, and constant oil density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

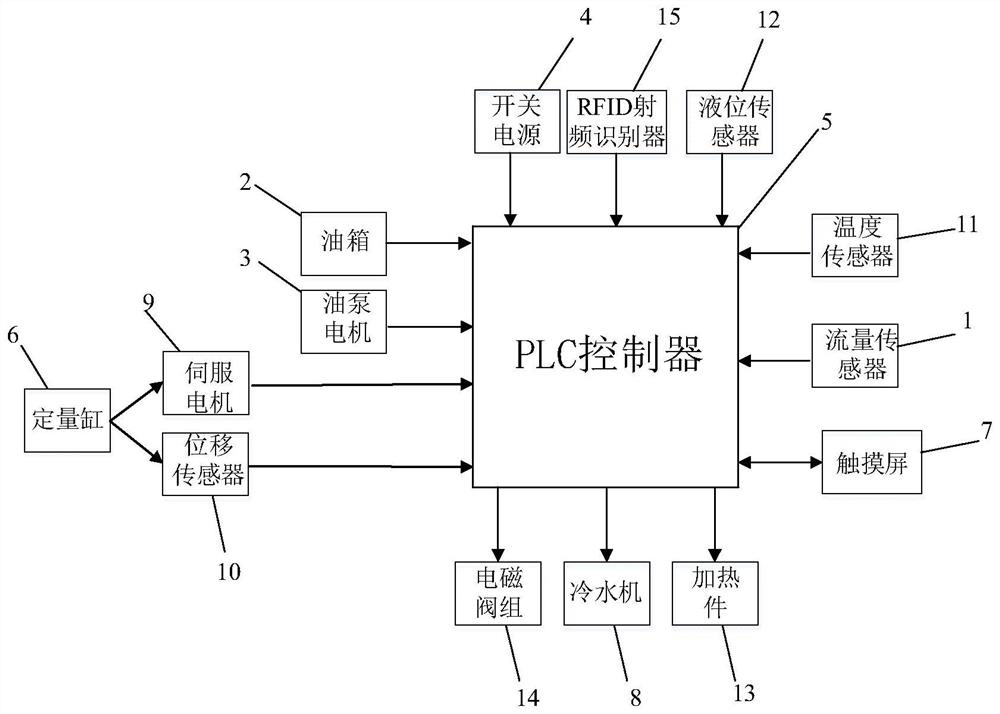

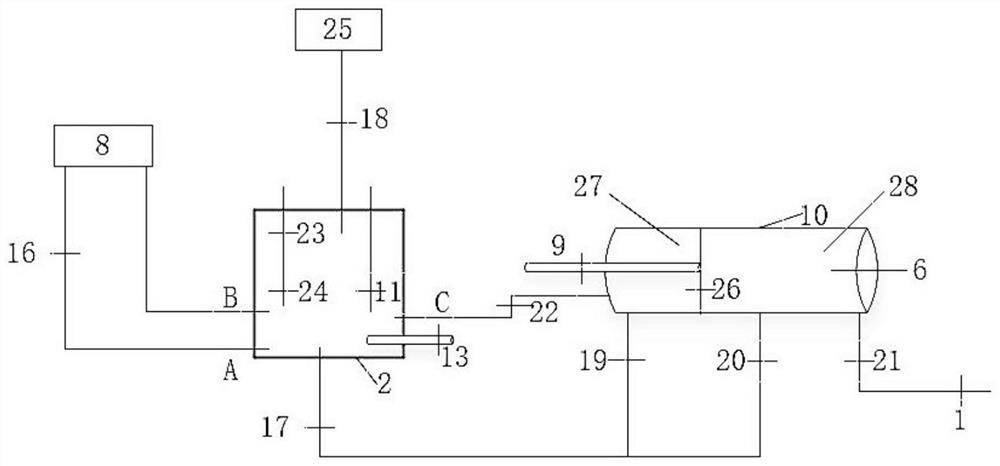

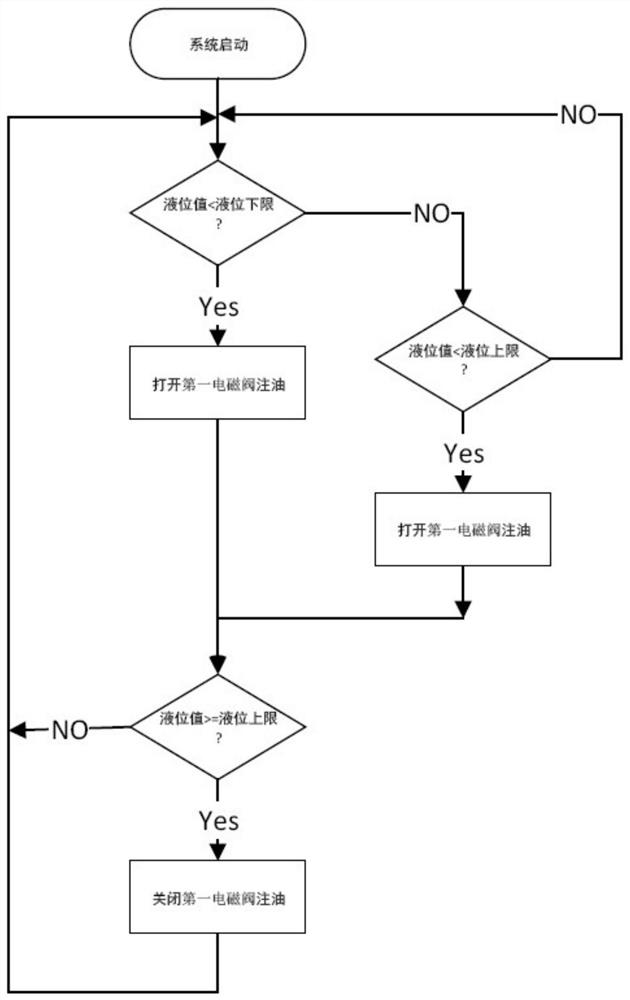

[0034] Such as figure 1 , 2 One embodiment of the present invention provides an automatic quantitative oil injection control system for a shock absorber, which includes a flow sensor 1, an oil tank 2, an oil pump motor 3, a PLC controller 5 powered by a switching power supply 4, a quantitative cylinder 6, Touch screen 7, chiller 8, servo motor 9, displacement sensor 10, temperature sensor 11, liquid level sensor 12, heating element 13, solenoid valve group 14, RFID radio frequency identifier 15.

[0035] Flow sensor 1, oil tank 2, oil pump motor 3, touch screen 7, chiller 8, servo motor 9, displacement sensor 10, temperature sensor 11, liquid level sensor 12, heating element 13, solenoid valve group 14, RFID radio frequency identification device 15 It is connected with the PLC controller 5, and the quantitative cylinder 6 is connected with the servo motor 9 and the displacement sensor 10.

[0036] The oil pump motor 3 is divided into an oil pump motor 1 16 and an oil pump mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com