Method and system for detecting looseness of bolts in wind driven generator, equipment and medium

A technology of wind power generator and detection method, which is applied in the monitoring of wind power generators, wind power generators, mechanical equipment, etc., to achieve the effect of low cost, simple setting and high value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

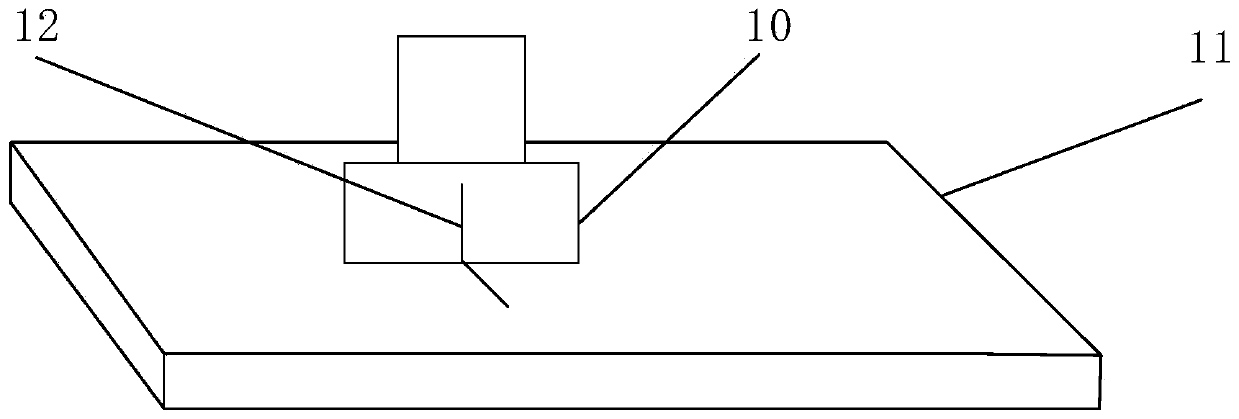

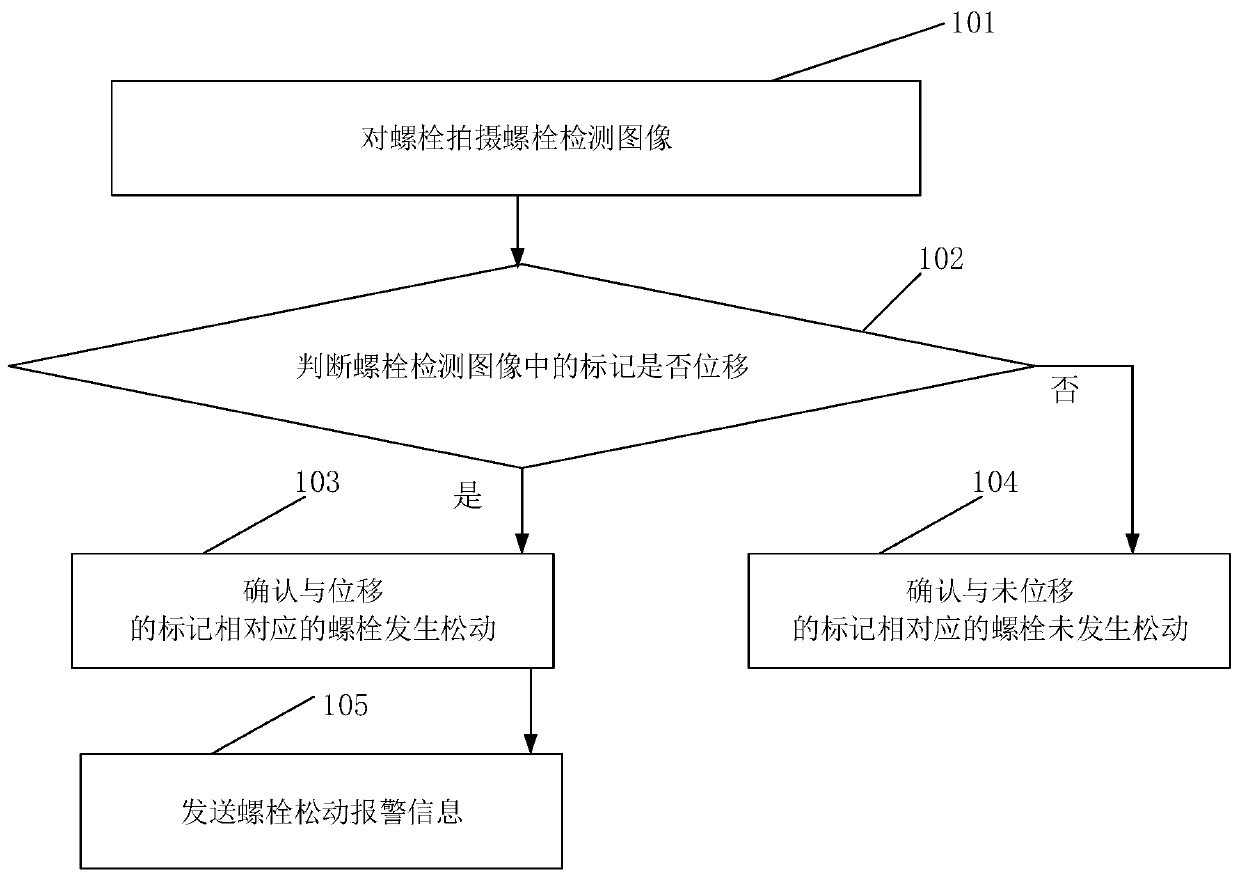

[0051] This embodiment provides a method for detecting bolt looseness in a wind power generator, figure 1 A schematic diagram showing the bolt mounting locations, such as figure 1 As shown, the wind power generator in this embodiment includes a plurality of bolts 10 arranged on the tower connecting layer 11, each bolt 10 and the tower connecting layer 11 have a preset mark 12 at a fixed position, and the preset mark 12 Including the first part and the second part, the first part is located on the bolt 10, and the second part is located on the tower connecting layer 11. When the bolt 10 is not loose, the preset mark 12 in the bolt detection image taken will not be displaced. In the embodiment, it is specifically embodied that the end positions of the first part and the second part are connected. Such as figure 2 As shown, the detection method in the present embodiment comprises:

[0052] Step 101, taking a bolt detection image for the bolt.

[0053] Step 102 , judging whet...

Embodiment 2

[0070] This embodiment provides a detection system for loose bolts in wind power generators, figure 1 A schematic diagram showing the bolt mounting locations, such as figure 1 As shown, the wind power generator in this embodiment includes a plurality of bolts 10 arranged on the tower connection layer 11, and each bolt 10 has a continuous preset mark 12 at a fixed position with the tower connection layer 11. Assuming that the mark 12 includes a first part and a second part, the first part is located on the bolt 10, and the second part is located on the tower connection layer 11. When the bolt 10 is not loose, the preset mark 12 will not appear in the bolt detection image taken Displacement, in this embodiment, is embodied in the connection between the ends of the first part and the second part. Such as Figure 5 As shown, the detection system includes: a bolt photographing module 201 , a loosening judgment module 202 and an alarm module 203 .

[0071] The bolt photographing ...

Embodiment 3

[0084] This embodiment provides an electronic device, which can be expressed in the form of a computing device (for example, it can be a server device), including a memory, a processor, and a computer program stored on the memory and operable on the processor, wherein the processor The bolt detection method in Embodiment 1 can be realized when the computer program is executed.

[0085] Figure 6 A schematic diagram of the hardware structure of this embodiment is shown, as Figure 6 As shown, the electronic device 9 specifically includes:

[0086] At least one processor 91, at least one memory 92, and a bus 93 for connecting different system components, including the processor 91 and the memory 92, wherein:

[0087] The bus 93 includes a data bus, an address bus, and a control bus.

[0088] The memory 92 includes a volatile memory, such as a random access memory (RAM) 921 and / or a cache memory 922 , and may further include a read only memory (ROM) 923 .

[0089] Memory 92 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com