Coating process for radio frequency circuit and radio frequency circuit

A radio frequency circuit and coating process technology, applied in circuit devices, printed circuit components, printed circuit secondary processing, etc., can solve problems such as reducing product environmental adaptability and greatly affecting circuit performance, achieving high practical value, The circuit performance is not affected, and the effect of improving the withstand voltage capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

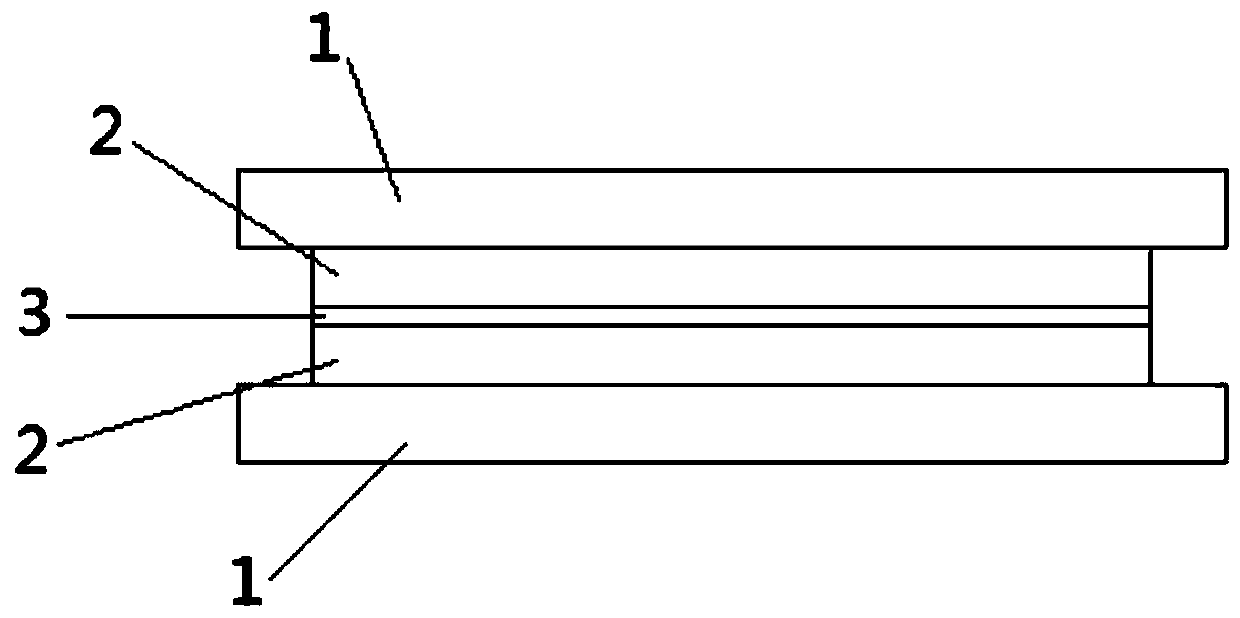

Image

Examples

Embodiment

[0034] A coating process for radio frequency circuits, comprising the steps of:

[0035] S1: PCB protective agent is selected as the coating material;

[0036] S2: Clean up the radio frequency circuit;

[0037] S3: drying the radio frequency circuit and cooling it to normal temperature;

[0038] S4: Coating the RF circuit multiple times: Use a three-proof coating device to coat the RF circuit with a PCB protective agent. After coating, put it in a high-temperature oven at 80°C to 90°C and bake it for 0.5 to 1 hour. Cool to room temperature and repeat this process several times.

[0039] Further, a coating process for radio frequency circuits, the PCB protectant in S1 and S4 is RH-35 type PCB protectant.

[0040] Further, a coating process for radio frequency circuits, the S2 is specifically cleaning iron filings, welding slag, and dirt on the surface of radio frequency circuits with alcohol.

[0041] Further, in a coating process for radio frequency circuits, the multiple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com