Small chlorine-containing disinfectant production equipment

A technology for production equipment and chlorine disinfection, applied in the direction of dissolving, mixing machines, chemical instruments and methods, etc., which can solve the problems of large volume of stirring reaction vessels, inability to flexibly change positions, and inability to apply to applicable occasions, etc., to achieve convenient production process and mixing The effect is good and the effect of reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

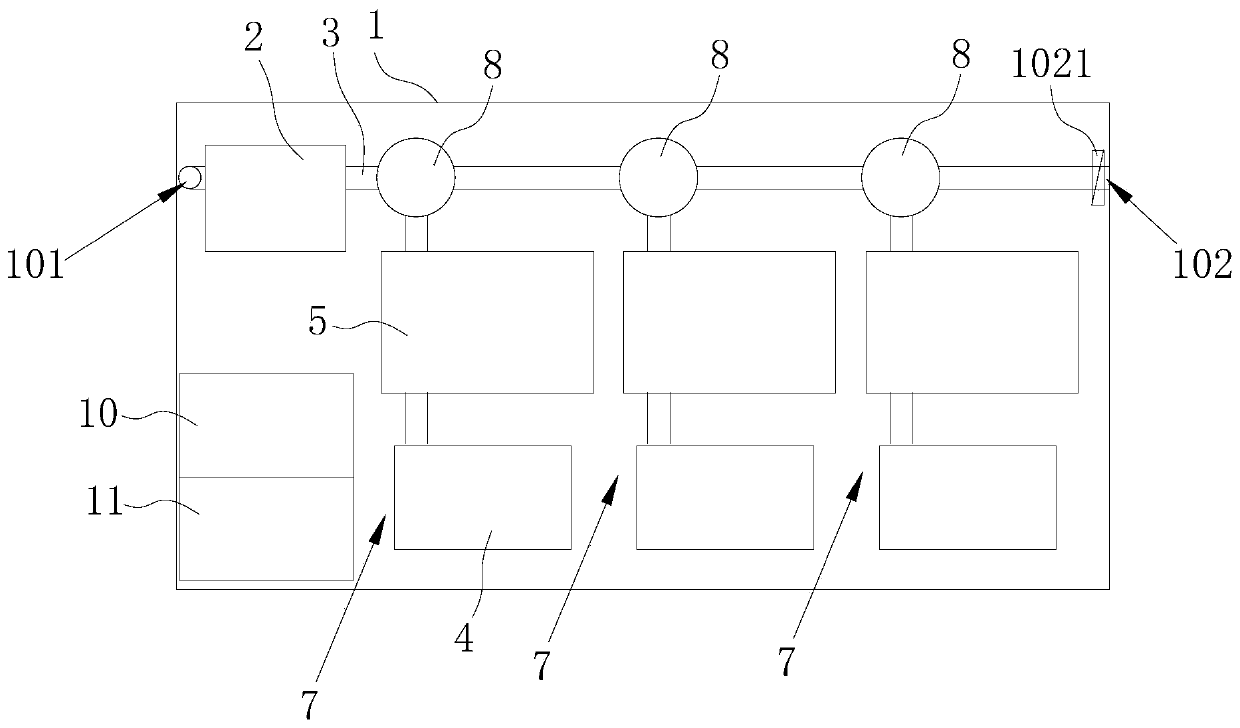

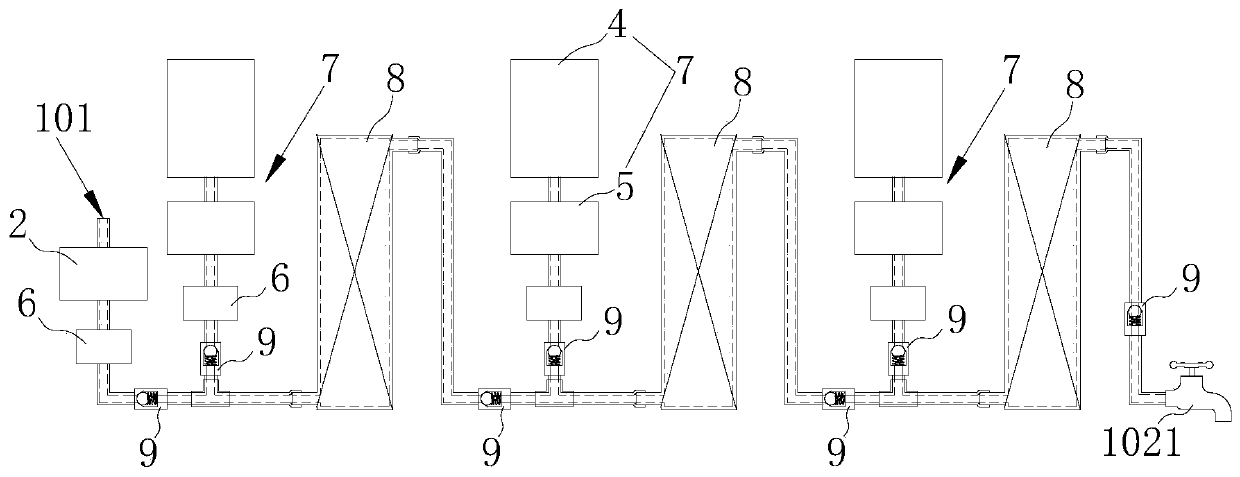

[0060] refer to figure 1 and figure 2 , this embodiment discloses a small chlorine-containing disinfectant production equipment, including a cabinet 1 and a miniature electric water pump 2 arranged in the cabinet 1, a connecting pipeline 3, several raw material storage tanks 4, several metering pumps 5, the components of the cabinet 1 One side is provided with a purified water inlet 101, and the other side is provided with a mixed solution outlet 102. The purified water inlet 101 is connected to an external water supply pipe to supply purified water to the cabinet 1 as a basic solution for producing disinfectant, and the mixed solution outlet 102 There is an on-off valve 1021, which may be a manual faucet in this embodiment, and may also be a solenoid valve in other embodiments.

[0061] A flow meter 6 is arranged at the purified water inlet 101, and the flow meter 6 is an electronic flow meter 6 to detect the water flow of the purified water inlet 101 in real time. The con...

Embodiment 2

[0101] refer to Figure 9 , the present embodiment discloses another kind of small-scale chlorine-containing disinfectant production equipment, based on embodiment 1, and the place that differs from embodiment 1 is:

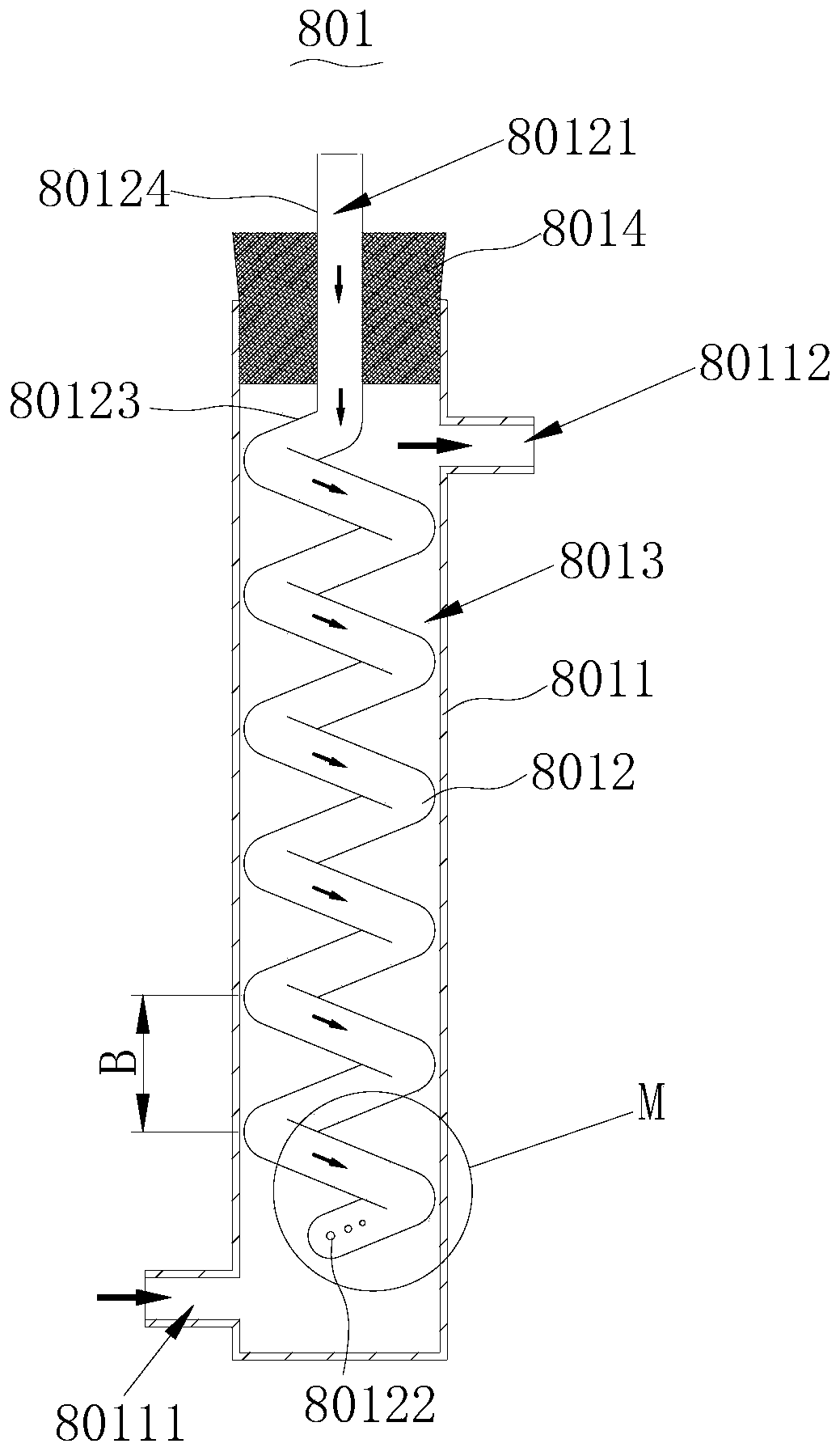

[0102] The second catheter 8012 includes a spiral tube body 80123 and a straight tube body 80124, the straight tube body 80124 and the spiral tube body 80123 are inserted into the sealing plug 8014 or connected through thread fit, and the straight tube body 80124 communicates with the spiral tube body 80123 , the second catheter tube 8012 can be divided into two sections for independent production. On the one hand, it can reduce the difficulty of production. On the other hand, according to the actual use needs of the mixed liquid, the helical tube body 80123 with different lengths and pitches can be replaced, and the space for change is large. , good replacement.

[0103] When connecting by thread fit, external threads (not shown) can be set on the outer walls o...

Embodiment 3

[0105] refer to Figure 10 , this embodiment discloses another kind of small-scale chlorine-containing disinfectant production equipment, based on the above-mentioned embodiment, and differs from the above-mentioned embodiment in that:

[0106] refer to Figure 10 , the first liquid inlet 80111 and / or the first liquid outlet 80112 and / or the second liquid inlet 80121 are provided with a first switch 8015, in this embodiment, the first liquid inlet 80111, the first liquid outlet 80112 , The second liquid inlet 80121 is provided with a first switch 8015.

[0107] refer to Figure 10 as well as Figure 11 , the first catheter tube 8011 is provided with an extended end 80113 at the end far away from the opening, and a through hole 801131 is provided at the extended end, and the extended end 80113 is adapted to the size of the opening. Specifically, the outer wall of the extended end 80113 cooperates with the inner wall of the opening to realize Plug-in connection, a sealing co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com