Manufacturing method for 3D printing polyimide part

A technology for printing polyimide and polyamide, applied in the field of 3D printing, can solve problems such as inability to maintain shape stability and precise size for a long time, difficulty in extrusion and printing of polyimide solution, size deformation, etc., and achieve potential application value , long-term shape stability and dimensional accuracy, and excellent structural retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a kind of preparation method of 3D printing polyimide parts, comprises the following steps:

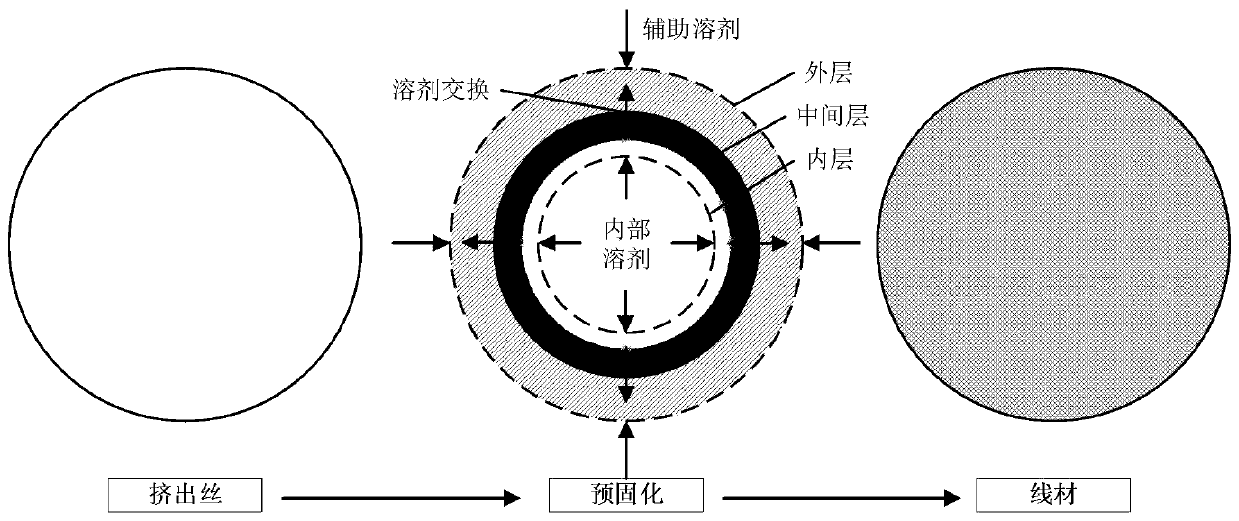

[0033] Extruding the polyamide solution to obtain an uncured wire;

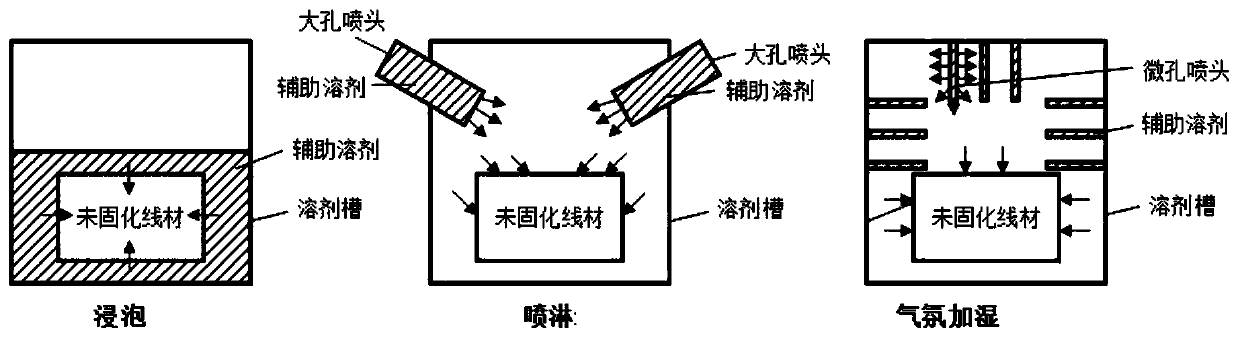

[0034] performing pre-curing and 3D printing on the uncured wire in sequence by using an auxiliary solvent to obtain a solid wire;

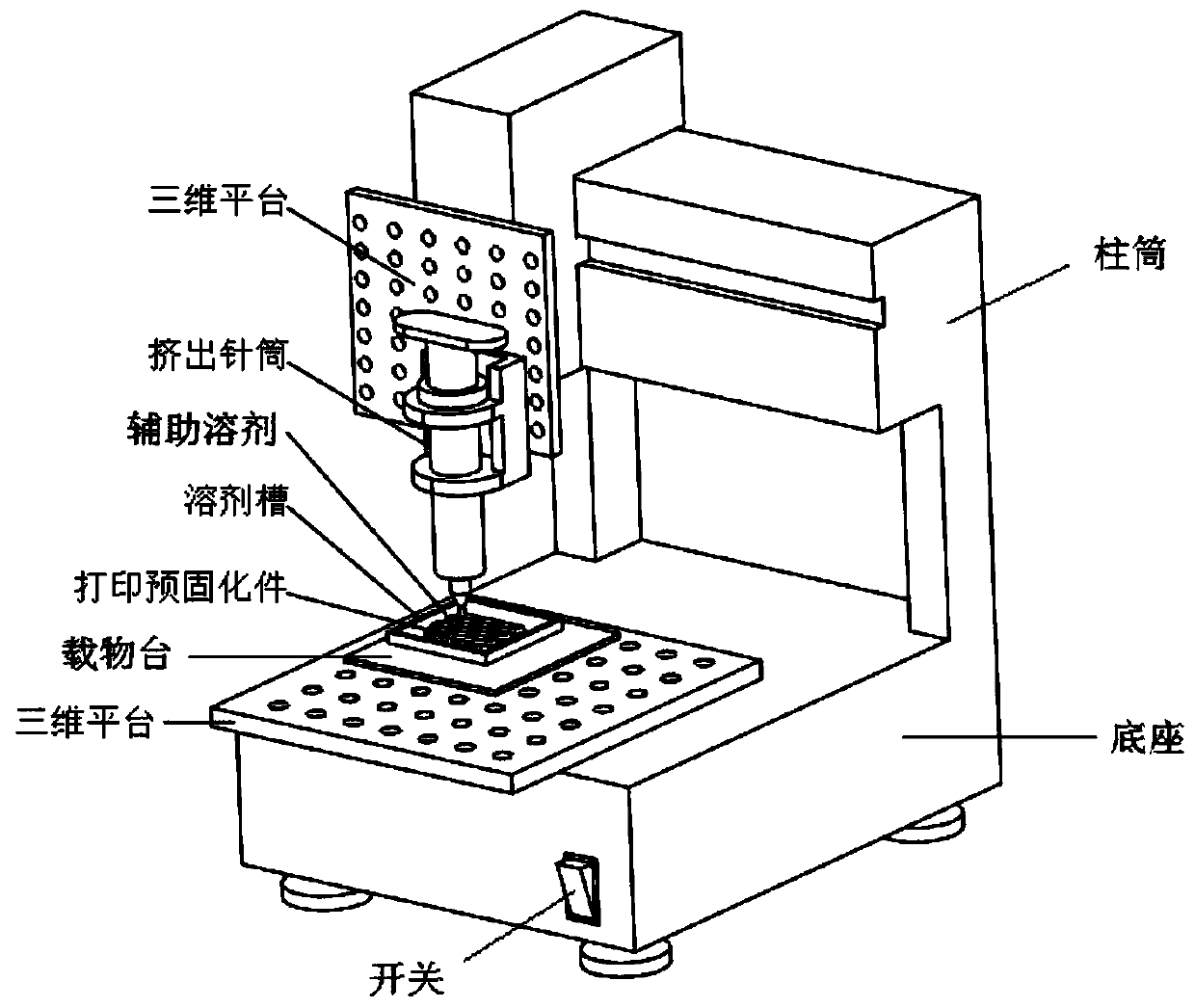

[0035] The solid wire is formed into a printing pre-cured part under the control of the three-dimensional platform;

[0036] Heat-treating the printed pre-cured part to obtain a 3D printed polyimide part;

[0037] The mass percentage of the polyamide solution is 5-60%, and the viscosity is 0.1-50000Pa·s;

[0038] The auxiliary solvent includes one or more of water, alcohol solvents, nitrogen-containing solvents, sulfur-containing solvents, ketone solvents and furan solvents.

[0039] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0040] The i...

Embodiment 1

[0062] use image 3 The device shown and Figure 4 For the preparation of the process flow shown, the polyamic acid solution (20% by mass, viscosity 10Pa·s) is placed in the extrusion syringe and extruded, the wire is extruded into the solvent tank, and the removed solution is sprayed. Ionized water is sprayed onto each surface of the wire for 20 minutes, and the uncured wire is pre-cured at room temperature to obtain a solid wire; the solid wire forms a printed pre-cured part under the control of the three-dimensional platform;

[0063] Under the condition of a pressure of 90kPa, put the printed pre-cured part in an oven for gradient heating heat treatment. The heating rate is constant at 2°C / min. After the temperature is raised to 100°C, it is kept for 2 hours, after the temperature is raised to 200°C, it is kept for 1 hour, and the temperature is raised. Heat it at 300°C for 1 hour, and heat it up to 350°C for 1 hour to obtain a 3D printed polyimide part.

[0064] In this...

Embodiment 2

[0066] use image 3 The device shown and Figure 4 For the preparation of the process flow shown, the polyamic acid solution (50% by mass, viscosity 10000Pa·s) is placed in the extrusion syringe and extruded, and the wire is extruded into the deionized water contained in the solvent tank , soaking at room temperature for 5 minutes, the uncured wire is pre-cured to obtain a solid wire; the solid wire forms a printed pre-cured part under the control of a three-dimensional platform;

[0067] Under the condition of a pressure of 90kPa, put the printed pre-cured part in an oven for gradient heating heat treatment. The heating rate is constant at 2°C / min. After the temperature is raised to 100°C, it is kept for 2 hours, after the temperature is raised to 200°C, it is kept for 1 hour, and the temperature is raised. Heat it at 300°C for 1 hour, and heat it up to 350°C for 1 hour to obtain a 3D printed polyimide part.

[0068] The diameter of the single filament of the printed pre-cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com