Visual stacking device and visual information processing method thereof

An information processing method and visual technology, applied in the field of visual technology applications, can solve the problems of unguaranteed product quantity and quality, large labor demand, and high labor costs, so as to save labor production costs, operate flexibly, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

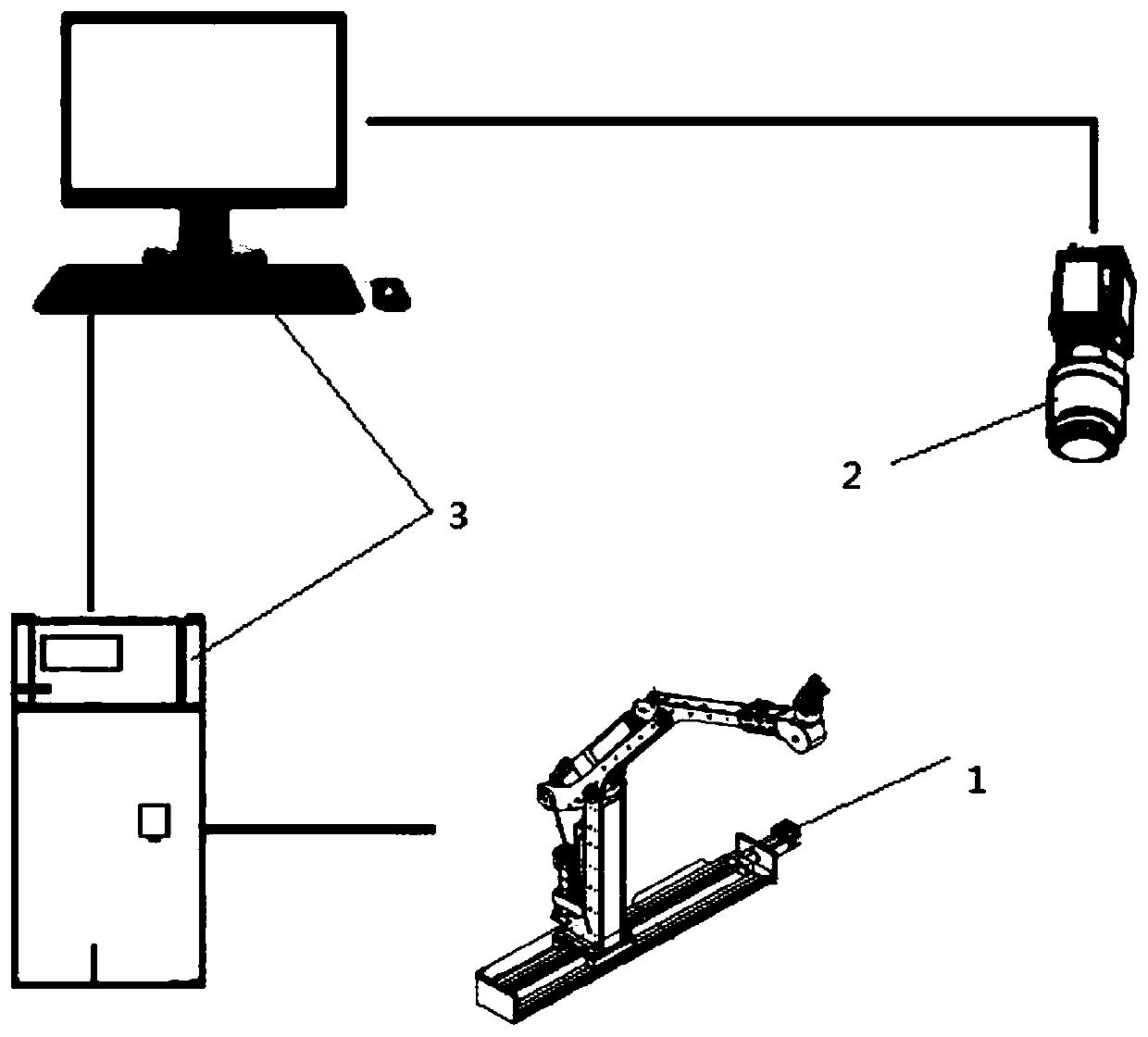

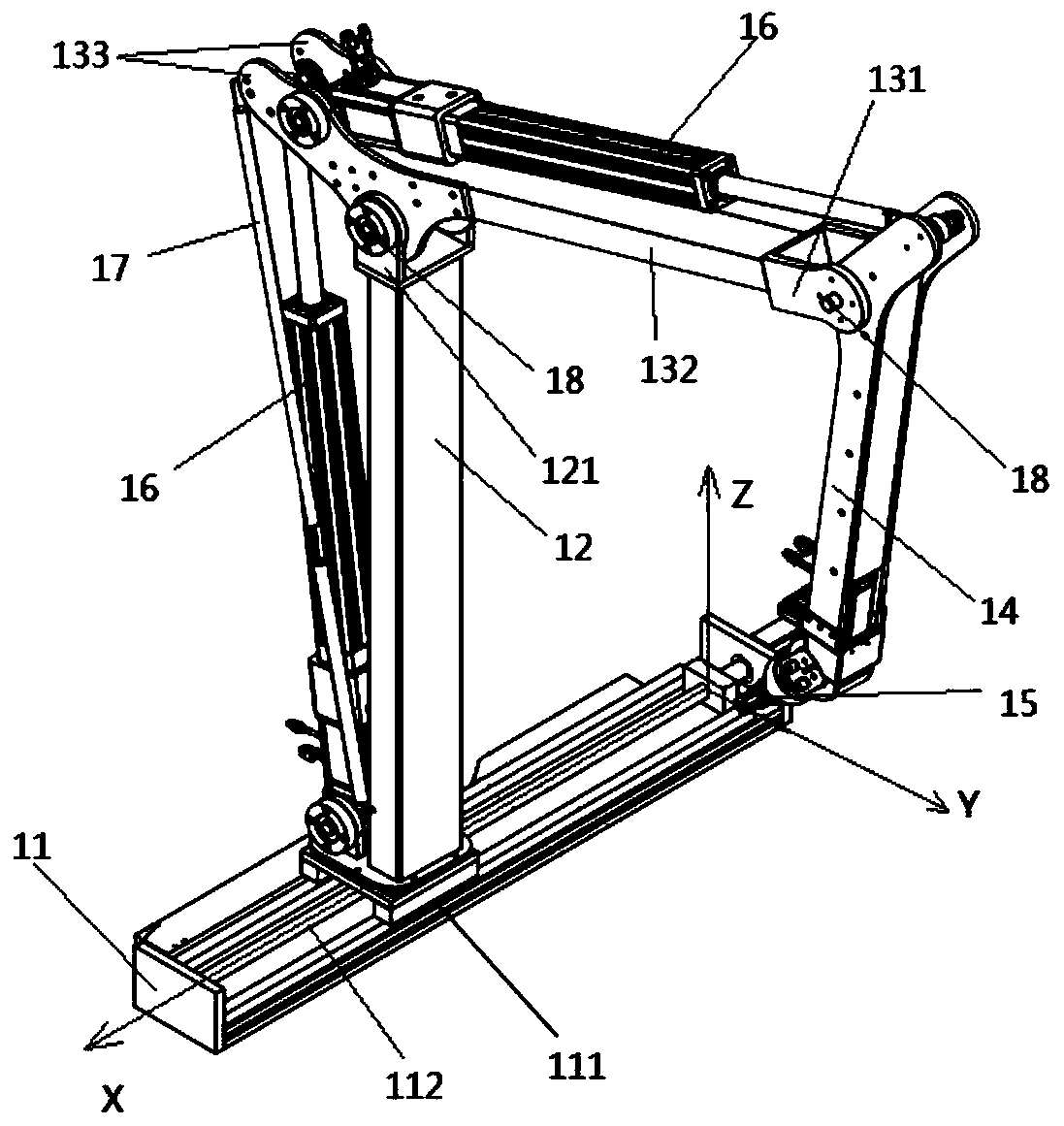

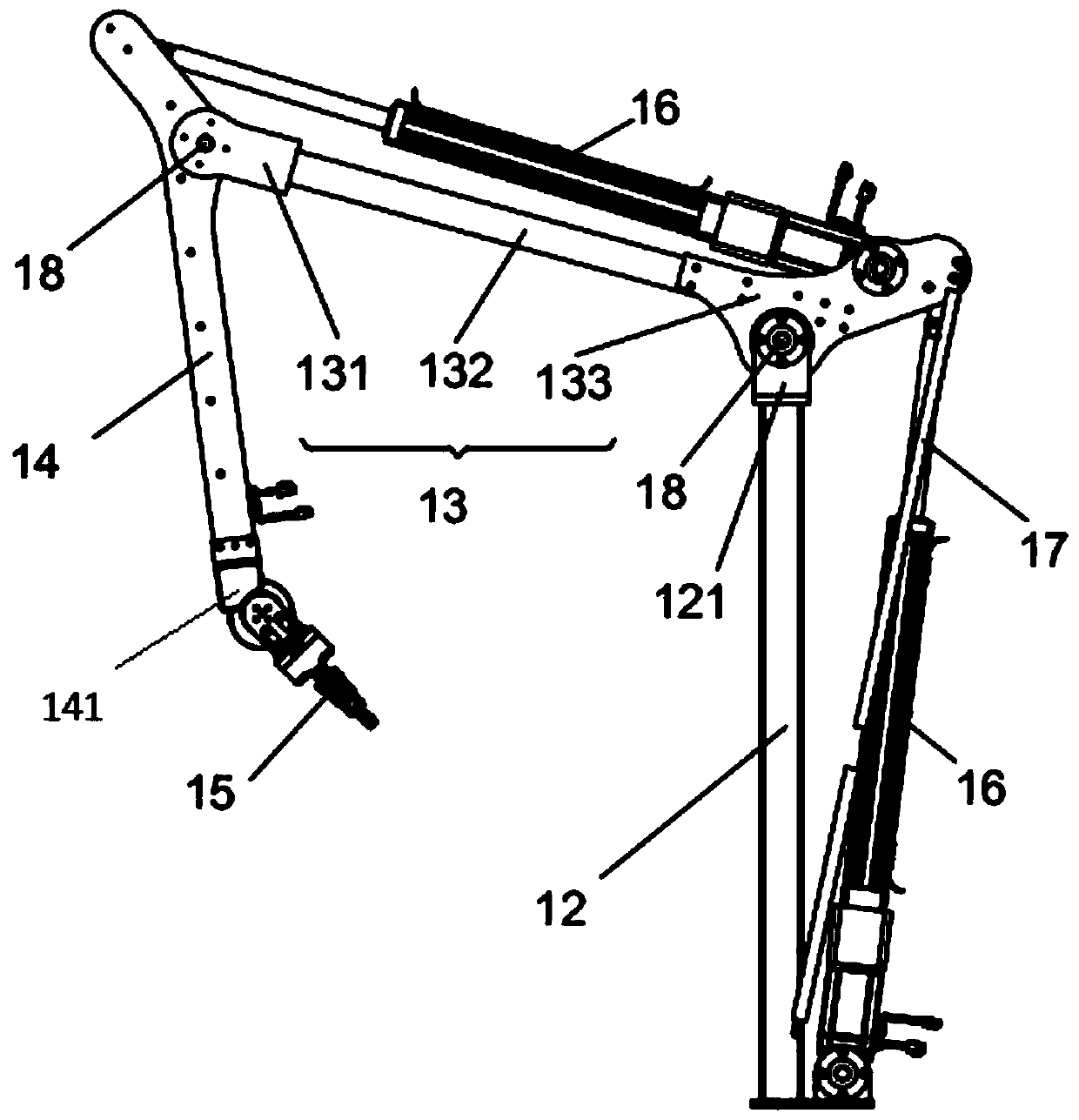

[0071] Please also refer to Figure 1 to Figure 7 Now, a specific implementation of a visual palletizing device provided by the present invention will be described. This kind of vision palletizing equipment includes, grasping device 1, information processing control equipment 3 and vision acquisition component 2, wherein vision acquisition component 2 is provided with image collector; Information processing control equipment 3 is electrically connected with vision acquisition component 2; The device 1 is electrically connected to the information processing control device 3 . Vision acquisition component 2 comprises image acquisition device and image acquisition card, and image acquisition device comprises industrial CCD (charge coupled device) camera and lens or CMOS (Complementary Metal Oxide Semiconductor) camera and lens, collects and transmits image information to image acquisition card, image acquisition The card includes an external acquisition card and a built-in board...

Embodiment 2

[0080]As a specific implementation of the embodiments of the present invention, please refer to Figure 1 to Figure 7 , the visual palletizing equipment of this embodiment is basically the same as that of Embodiment 1, the difference is that the image collector and the grabbing device 1 adopt the Eye-to-Hand combination method, specifically, the image collector is fixed on the grabbing device 1, it is generally fixed on the bracket of the purposely built target workpiece placement platform, and is not connected to the grabbing device 1. The position and posture of the image collector remain unchanged during the entire grabbing operation. This setting is due to the position of the image collector Keep it fixed all the time, reduce the requirements for the flexibility of the cable material and the wiring position is convenient for actual on-site operations. After the image collector is calibrated, the calibration parameters are constant values, which reduces the subsequent calibr...

Embodiment 3

[0082] As a specific implementation of the embodiments of the present invention, please refer to Figure 1 to Figure 7 , the visual palletizing device of this embodiment is basically the same as that of Embodiment 1, the difference being that the specific implementation process is as follows: first, the image collector is installed on the grabbing device 1, and the grabbing device 1 is moved to the photographing location to take pictures Return the image in RGB format, and output the data in point cloud format at the same time. Secondly, the processing of the picture by the information processor 33 includes grayscale processing. After the grayscale processing, it is easy to distinguish image features, perform threshold segmentation to extract features, and make an image template. Through edge detection again, the corresponding shape of the minimum circumscribed object is obtained, and the center point in the object image is calculated for output. After obtaining the depth dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com