Method for recovering chromium resources in electric furnace stainless steel slag

A technology for recycling stainless steel slag and resources, applied in the field of comprehensive utilization of metallurgical solid waste resources, can solve the problems of difficult recovery of chromium resources, small size of spinel, and high processing cost, and achieve the advantages of inhibiting dissolution risk, improving grade and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

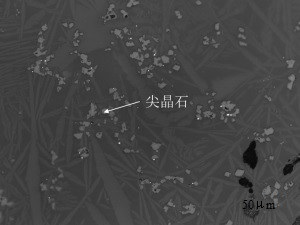

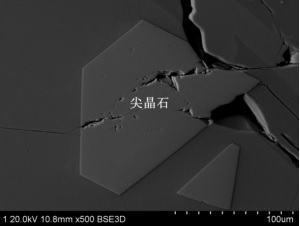

[0035] After the stainless steel slag produced by the electric furnace is normally released, the high temperature stainless steel slag is put into the slag tank. The main components of the stainless steel slag are CaO 45%, SiO 2 30%, MgO 8%, Al 2 O 3 4%, FeO 3%, Cr 2 O 3 5%, the crystal phase of the stainless steel slag is as follows figure 1 shown.

[0036] will Al 2 O 3 and SiO 2 The modifier is added to the high temperature stainless steel slag, and makes the stainless steel slag and Al 2 O 3 The additives are mixed uniformly to form a molten mixed slag, in which Al 2 O 3 The mass of the additive is 4% of the stainless steel slag, SiO 2 The mass of the additive is 10% of the stainless steel slag, SiO 2 and Al 2 O 3 grinding to a particle size of ≤74 mesh; the basicity of the modified stainless steel slag ( w (CaO) / w (SiO 2 )) around 1.1, Al 2 O 3 The content is close to 7%.

[0037] The stainless steel slag after high temperature modification was low...

Embodiment 2

[0039] After the stainless steel slag produced by the electric furnace is normally released, the high temperature stainless steel slag is put into the slag tank. The main components of the stainless steel slag are CaO 45%, SiO 2 30%, MgO 8%, Al 2 O 3 4%, FeO 3%, Cr 2 O 3 5%.

[0040] will Al 2 O 3 and SiO 2 The modifier is added to the high temperature stainless steel slag, and makes the stainless steel slag and Al 2 O 3 and SiO 2 The additives are mixed uniformly to form a molten mixed slag, in which Al 2 O 3 The mass of the additive is 8% of the stainless steel slag, SiO 2 The mass of the additive is 10% of the stainless steel slag, SiO 2 and Al 2 O 3 grinding to a particle size of ≤74 mesh; the basicity of the modified stainless steel slag ( w (CaO) / w (SiO 2 )) around 1.1, Al 2 O 3 The content is close to 10%.

[0041] The stainless steel slag after high temperature modification was lowered to 1300°C at 3°C / min, and kept for 60min. The chromium in t...

Embodiment 3

[0043] After the stainless steel slag produced by the electric furnace is normally released, the high temperature stainless steel slag is put into the slag tank. The main components of the stainless steel slag are CaO 45%, SiO 2 30%, MgO 8%, Al 2 O 3 4%, FeO 3%, Cr 2 O 3 5%.

[0044] will Al 2 O 3 and SiO 2 The modifier is added to the high temperature stainless steel slag, and makes the stainless steel slag and Al 2 O 3 The additives are mixed uniformly to form a molten mixed slag, in which Al 2 O 3 The mass of the additive is 12% of the stainless steel slag, SiO 2 The mass of the additive is 15% of the stainless steel slag, SiO 2 and Al 2 O 3 grinding to a particle size of ≤74 mesh; the basicity of the modified stainless steel slag ( w (CaO) / w (SiO 2 )) around 1.0, Al 2 O 3 The content is close to 13%.

[0045] The stainless steel slag after high temperature modification was lowered to 1300°C at 3°C / min, and kept for 30min. The chromium in the treated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com