A kind of preparation method of fine grain high specific gravity tungsten alloy

A high specific gravity, tungsten alloy technology, applied in the direction of additive manufacturing, energy efficiency improvement, process efficiency improvement, etc., can solve the problems of increasing manufacturing cost and manufacturing difficulty, complex preparation process, complicated process, etc. Simple and efficient material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

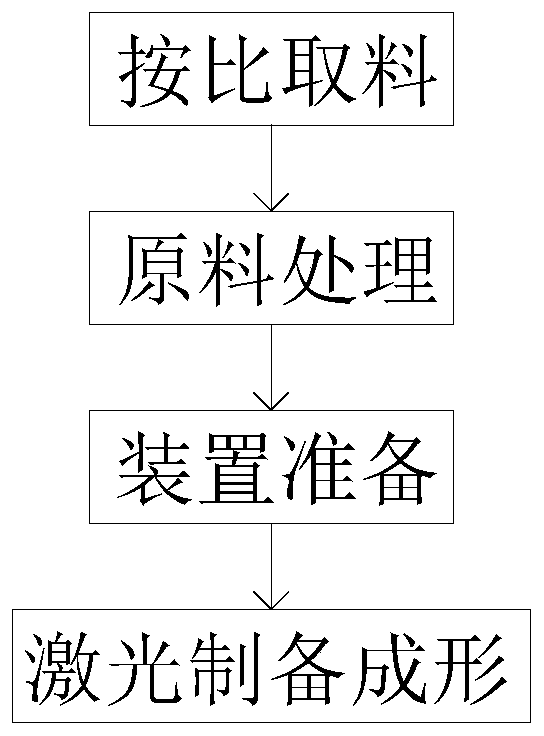

[0029] The purpose of this embodiment is to provide a method for preparing fine-grained high-density tungsten alloys with high material utilization, no need for molds, simple preparation process, short preparation cycle, and high degree of automation, such as figure 1 shown, including the following steps:

[0030] (1) Taking materials according to the ratio: take the raw materials according to the following parts by weight and mix them to obtain mixed powder: 80-95 parts of pure tungsten powder, 5-20 parts of pure metal binder phase powder; the average particle size of the pure tungsten powder is 5-20 parts 20 microns, and the shape of tungsten powder is spherical, spherical or polygonal, so as to make it different from the pure metal binder phase powder; the average particle size of the pure metal binder phase powder is 30-150 microns, and the pure The metal binder phase powder can be tungsten powder, any powder of nickel powder, iron powder, copper powder, cobalt powder, man...

example

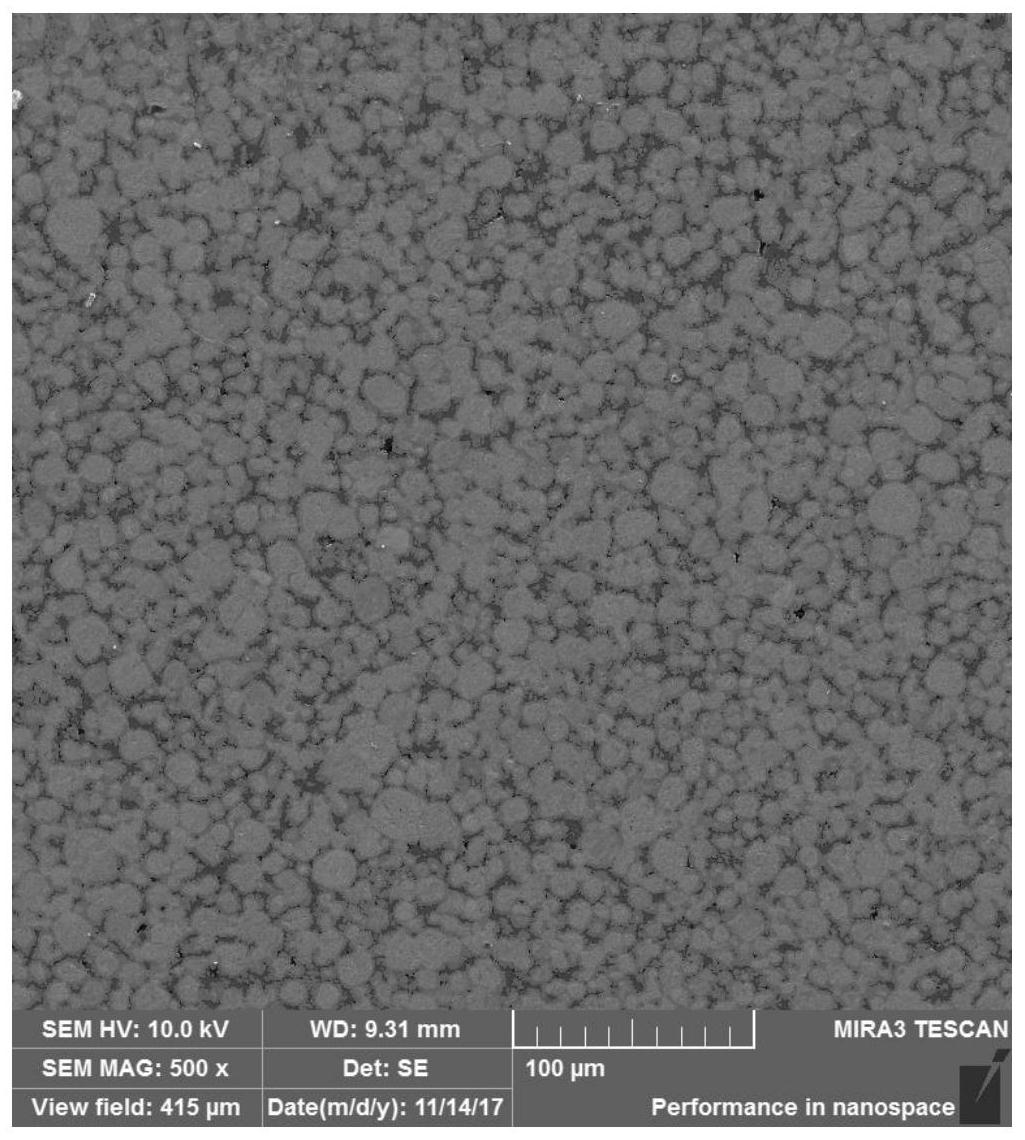

[0036] Example: Using laser rapid prototyping technology to prepare thin-walled samples of fine-grained high-density tungsten-nickel-iron alloy.

[0037] This preparation process comprises the following steps:

[0038] (1) Sieve commercial tungsten powder, iron powder, and nickel powder to obtain tungsten powder, nickel powder, and iron powder with an average particle size of 10 microns, 30 microns, and 130 microns, respectively, wherein the tungsten powder is polygonal in shape, and the nickel powder And the shape of iron powder is spherical. Weigh the powder according to the weight ratio of tungsten: nickel: iron = 90:7:3, put the powder into the material tank of the three-dimensional mixer, add stainless steel springs to promote stirring during the mixing process, and the mixing time is 1.5 hours.

[0039] (2) The mixed powder is baked in a vacuum oven at 80°C for 2 hours and then loaded into the powder feeder barrel of the laser rapid prototyping system. High-purity argon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com