Method for obtaining inlet pressure loss model coefficient through metering

A technology of inlet pressure and model coefficient, applied in the direction of electrical digital data processing, design optimization/simulation, special data processing applications, etc., can solve the problems of no disclosure, achieve accurate results, simple and easy operation of data processing process, and prevent waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

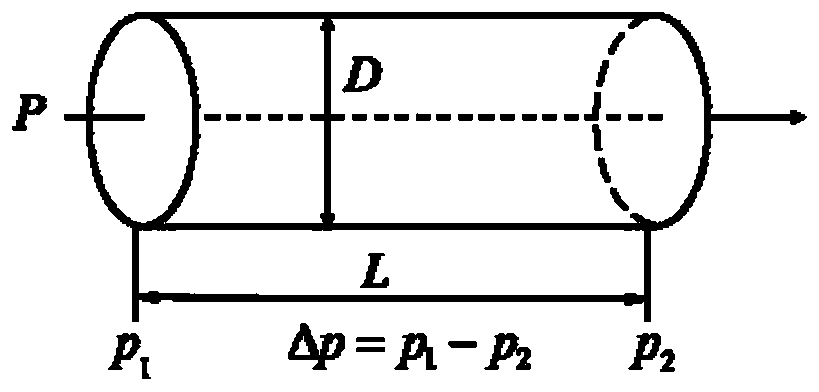

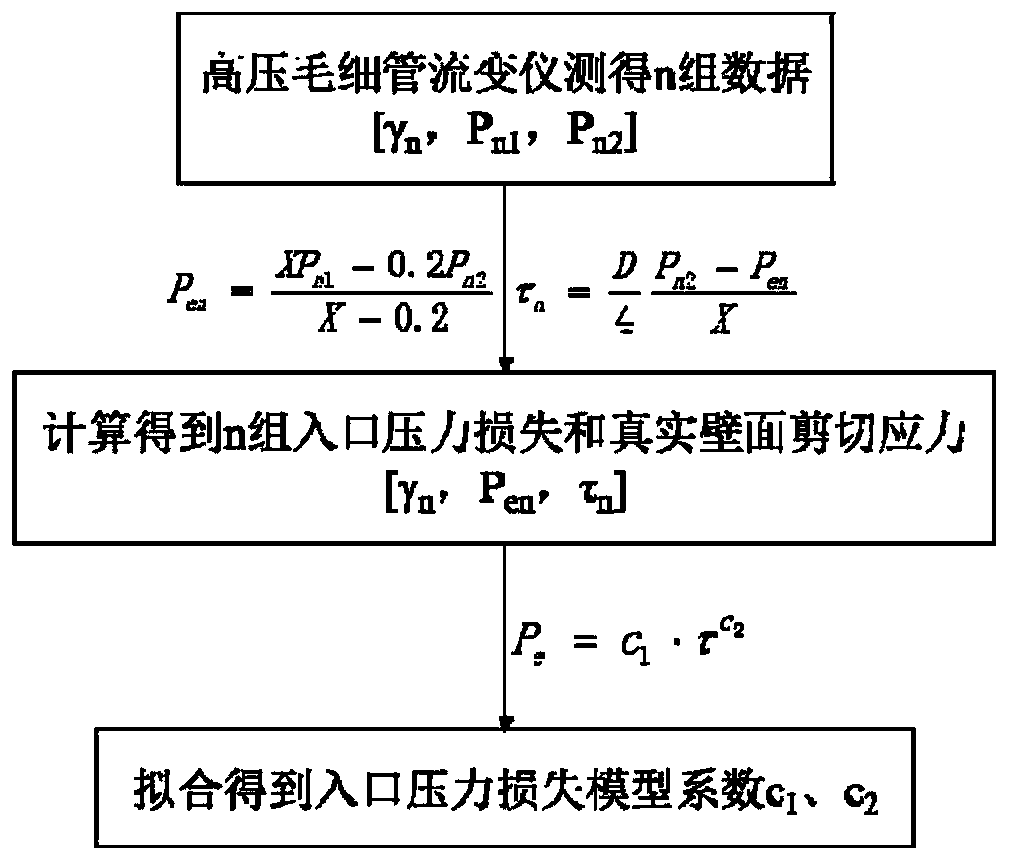

Method used

Image

Examples

Embodiment 1

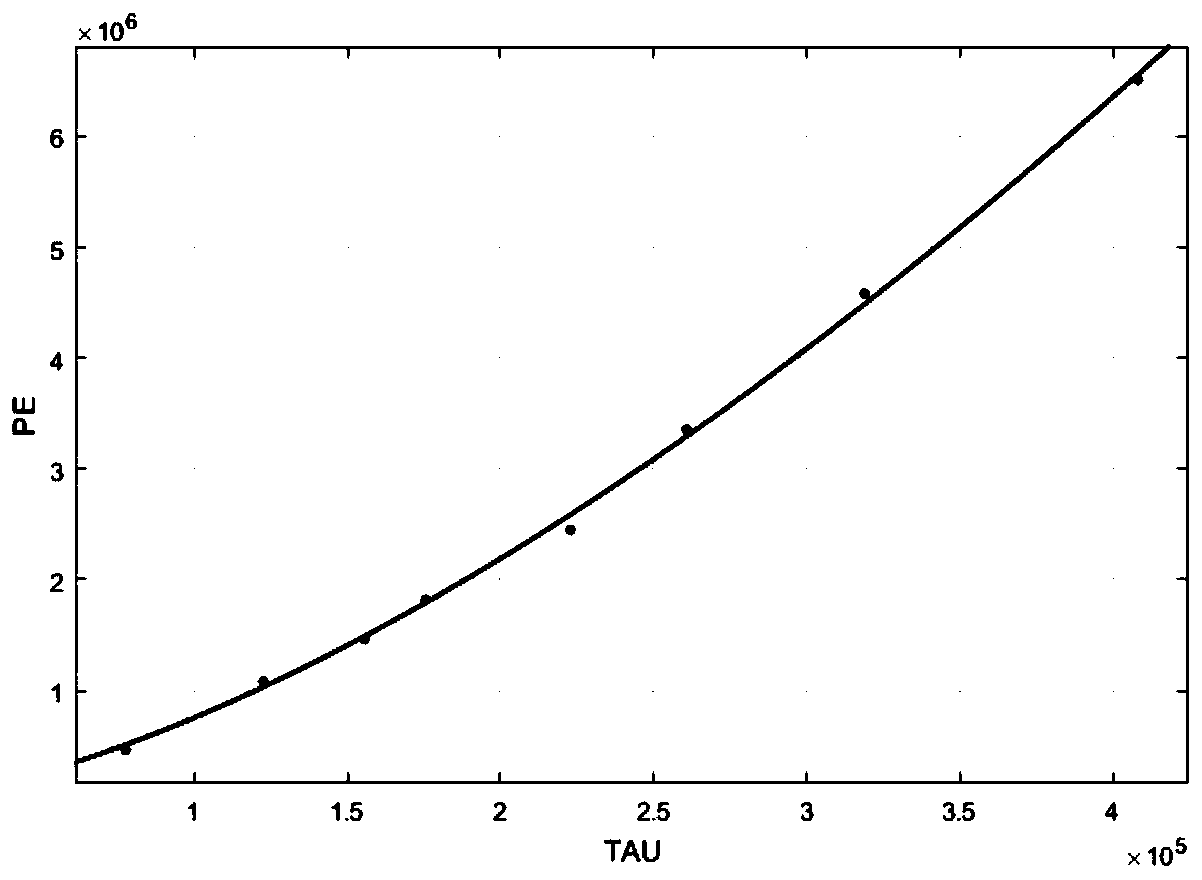

[0078] The inlet pressure loss model coefficient c of embodiment 1 polybutylene terephthalate+glass fiber 1 and c 2 the acquisition of

[0079] Grade: PBT-RG301 BK016G

[0080] Manufacturer: Kingfa Technology Co., Ltd.

[0081] Material: polybutylene terephthalate + glass fiber

[0082] 1) Obtain about 100g of the material to be tested and dry it for later use, and dry it in an oven at 120°C for 4 hours. The material is taken out of the oven and the test starts within 15 minutes to prevent secondary moisture absorption from affecting the test results.

[0083] 2) Set the high-pressure capillary test temperature to the recommended injection temperature of 240°C for the material. When the instrument reaches the test temperature, wait for about 15 minutes to keep the instrument stable.

[0084] 3) Install the capillary, put the capillary into the mounting nut, then put the mounting nut into the torque wrench connector, screw in the capillary and tighten it, tighten it with a...

Embodiment 2

[0102] Inlet pressure loss model coefficient c of embodiment 2 polycarbonate 1 and c 2 the acquisition of

[0103] Grade: Panlite L-1225LM

[0104] Manufacturer: Teijin Corporation

[0105] Material: Polycarbonate

[0106] 1) Obtain about 100g of Panlite L-1225LM material to be tested and dry it for later use, and dry it in an oven at 120°C for 4 hours. The material is taken out of the oven and the test starts within 15 minutes to prevent secondary moisture absorption from affecting the test results.

[0107] 2) Set the high-pressure capillary test temperature to the recommended injection temperature of 295°C for the material. When the instrument reaches the test temperature, wait for about 15 minutes to keep the instrument stable.

[0108] 3) Install the capillary, put the capillary into the mounting nut, then put the mounting nut into the torque wrench connector, screw in the capillary and tighten it, tighten it with a torque wrench, the torque is 65Nm. Due to the high...

Embodiment 3

[0126] Inlet pressure loss model coefficient c of embodiment 3 polycarbonate+carbon black 1 and c 2 the acquisition of

[0127] Brand: JH820-M30 BK201

[0128] Manufacturer: Kingfa Technology Co., Ltd.

[0129] Material: Polycarbonate + Carbon Black

[0130] 1) Obtain about 100g of JH820-M30 BK201 material to be tested and dry it for later use, and dry it in an oven at 120°C for 4 hours. The material is taken out of the oven and the test starts within 15 minutes to prevent secondary moisture absorption from affecting the test results.

[0131] 2) Set the high-pressure capillary test temperature to the recommended injection temperature of 295°C for the material. When the instrument reaches the test temperature, wait for about 15 minutes to keep the instrument stable.

[0132] 3) Install the capillary, put the capillary into the mounting nut, then put the mounting nut into the torque wrench connector, screw in the capillary and tighten it, tighten it with a torque wrench, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com