Strip-type dielectric patch filtering antenna array

A technology for filtering antennas and media, which is applied in the direction of antenna arrays, antenna arrays that are energized separately, and antennas, etc., can solve the problems of unfavorable filtering antenna array structure simplification, lack of array filtering function fusion, and large media size, etc., to achieve size reduction and simplification structure, maintaining the effect of the half-wave distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings.

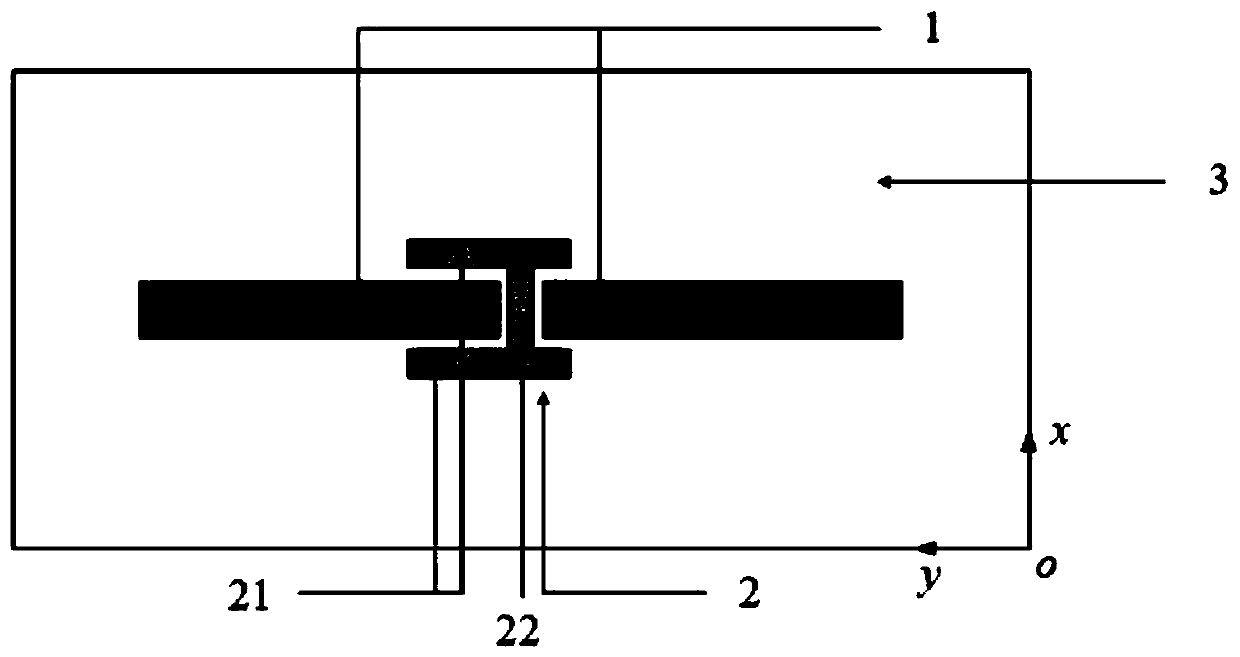

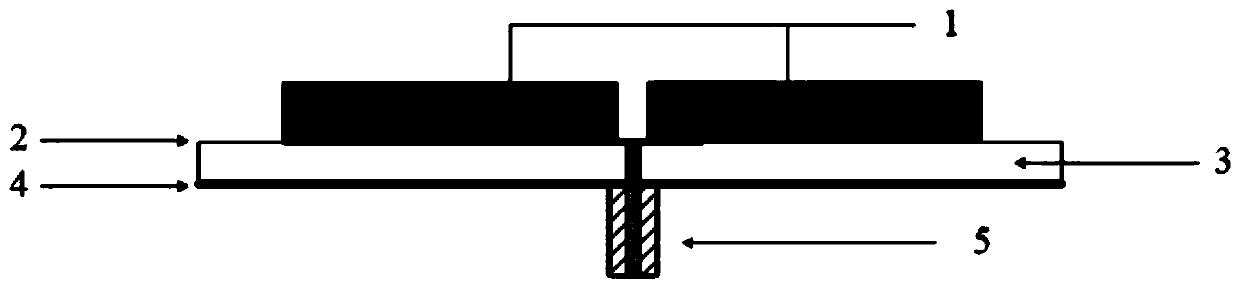

[0019] Such as figure 1 , figure 2 As shown, a strip dielectric patch filter antenna array includes two dielectric strips 1 , an H-shaped metal structure 2 , a dielectric substrate 3 , a metal ground 4 and a coaxial cable 5 . The H-shaped metal structure 2 is located on the upper surface of the dielectric substrate 3 , and the H-shaped metal structure 2 is composed of two metal strips 21 parallel to the y-axis and a metal strip 22 parallel to the x-axis. Two dielectric strips 1 are stacked above the dielectric substrate 3 , respectively located on both sides of the metal strip 22 on the x-axis and arranged parallel to the y-axis. The metal ground 4 is located on the lower surface of the dielectric substrate 3 , and the inner conductor of the coaxial line 5 penetrates from the bottom of the metal ground 4 and is connected to the center of the metal strip 22 .

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com