Fermented soya bean processing technology

A processing technology, the technology of fermented soya bean, which is applied in the field of fermented soya bean processing technology, can solve the problems such as long fermenting time of fermented soya bean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: a kind of fermented soya bean processing technology, comprises the following steps: selecting beans, soaking, draining, steaming, fermenting, drying;

[0019] The soaking conditions are as follows: the pH value of the soaked beans water is 7.7, the soaked beans water temperature is 365°C, the amount of beans (g): the amount of water (mL) is 1:4, and the soaking time is 8 hours;

[0020] The cooking conditions are as follows: mix soaked soybeans with bran, add water and mix well, wrap them with gauze, and sterilize at 121°C for 30 minutes;

[0021] The fermentation conditions are: add salt and Bacillus natto to the steamed soybeans, the ratio of soybeans to salt is 93:7, mix well, and then put them into the fermentation cylinder for fermentation. The temperature in the fermentation cylinder is 47°C during fermentation.

Embodiment 2

[0022] Embodiment 2: a kind of fermented soya bean processing technology, comprises the following steps: selecting beans, soaking, draining, steaming, fermenting, drying;

[0023] The soaking conditions are as follows: the pH value of the soaked beans water is 7.8, the soaked beans water temperature is 367°C, the amount of beans (g): the amount of water (mL) is 1:4, and the soaking time is 9 hours;

[0024] The cooking conditions are as follows: mix soaked soybeans with bran, add water and mix well, wrap them with gauze, and sterilize at 124°C for 30 minutes;

[0025] The fermentation conditions are as follows: add salt and Bacillus natto to the cooked soybeans, the ratio of soybeans to salt is 93:7, mix well, and then put them into the fermentation cylinder for fermentation. The temperature in the fermentation cylinder is 50°C during fermentation.

Embodiment 3

[0026] Embodiment 3: a kind of fermented soya bean processing technology, comprises the following steps: selecting beans, soaking, draining, steaming, fermenting, drying;

[0027] Wherein the soaking conditions are: the pH value of the soaked beans water is 7.9, the soaked beans water temperature is 369° C., the amount of beans (g): the amount of water (mL) is 1:4, and the soaking time is 10 hours;

[0028] The cooking conditions are as follows: mix soaked soybeans with bran, add water and mix well, wrap them with gauze, and sterilize at 126°C for 30 minutes;

[0029] The fermentation conditions are as follows: add salt and Bacillus natto to the steamed soybeans, the ratio of soybeans to salt is 93:7, mix well, and then put them into the fermenter for fermentation. The temperature in the fermenter is 53°C during fermentation.

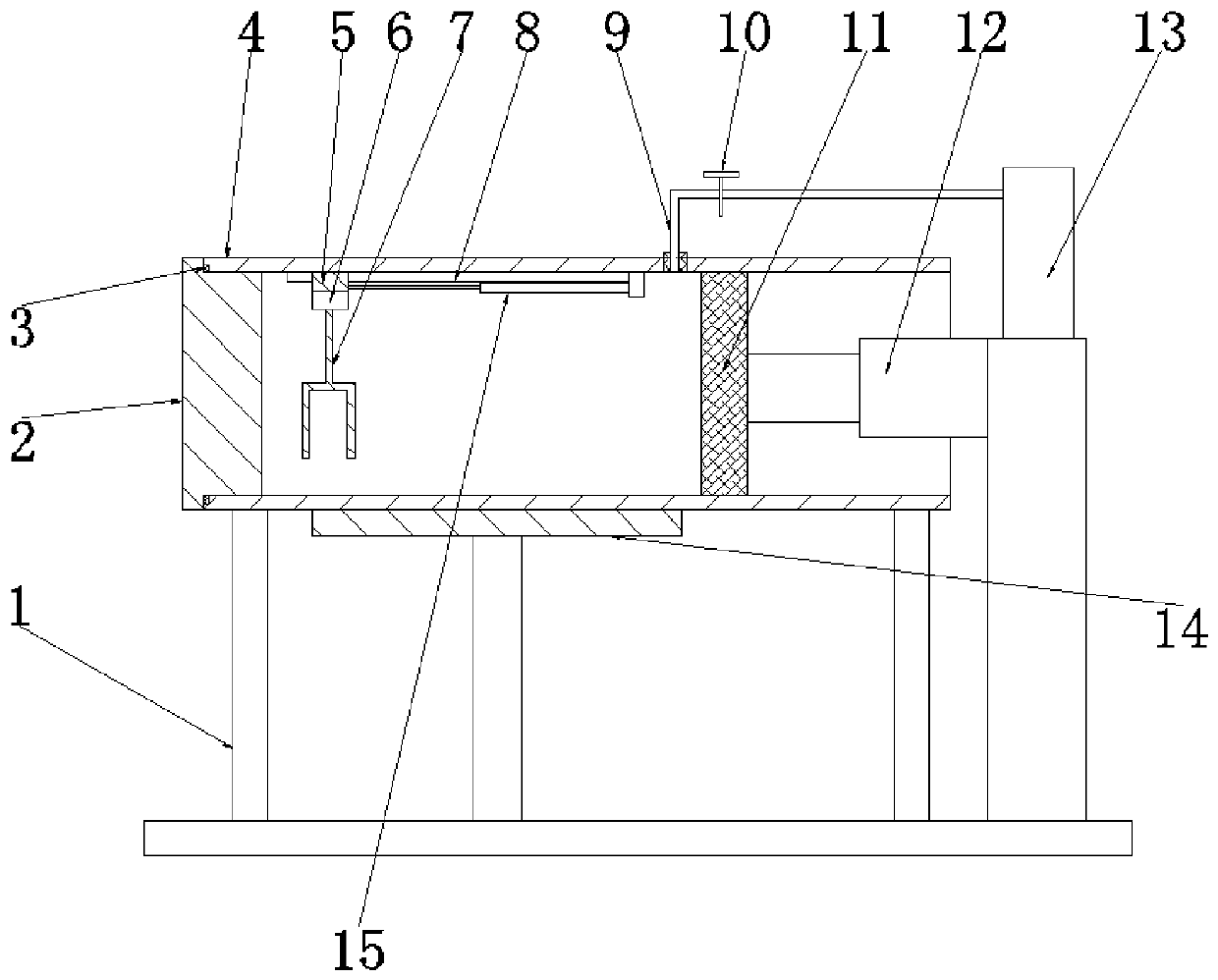

[0030] The fermenting drum among the embodiment 1-3 is basically as attached figure 1 Shown:

[0031] Fermentation cylinder 4 is fixed on the ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com