Preparation method of bulbus lilii powder

The technology of a lily powder and lily powder, which is applied in the field of preparation of lily powder, can solve the problem of high starch content of lily, achieve the effects of increasing defecation volume and preventing intestinal inflammatory diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

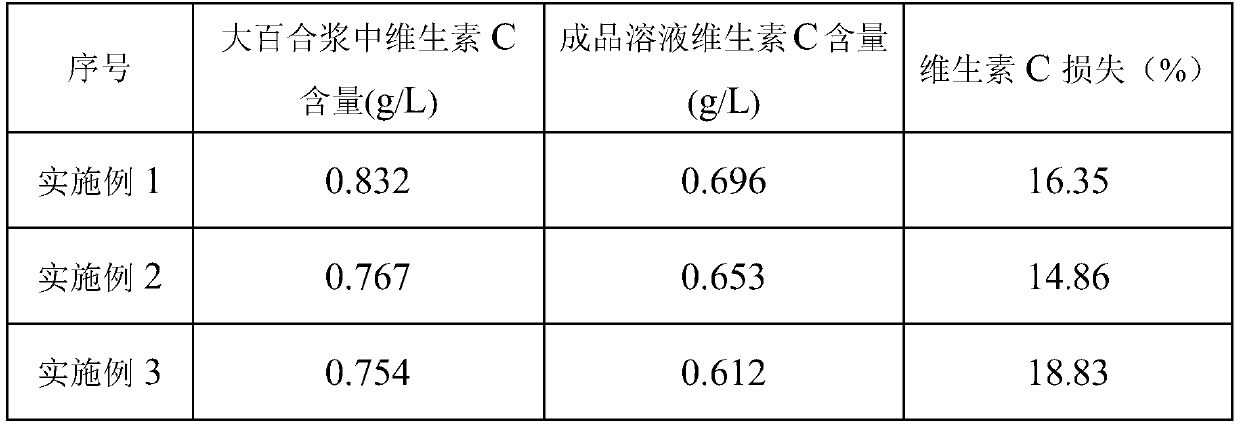

Examples

Embodiment 1

[0023] Harvest the big lily bulbs, peel off the scales, wash 3 times to remove the sediment, filter out the water, add 2 times the weight of water for beating treatment, filter through a 100-mesh sieve, collect the filtrate for concentration, and concentrate to 1 / 5 of the weight of the filtrate. solution, add lysine and mix, the mass ratio of lysine and dalilia scales is 1:10, adjust the pH to 7 with 2% sodium hydroxide solution, and let it stand for 10 minutes. Add 40% mass concentration of citric acid aqueous solution, the weight ratio of citric acid contained in the citric acid aqueous solution to dalilia scales is 1:3, mix and stand for 3 hours and then dry at 30°C for 10 hours; place the obtained dried product in an oven at 130°C for reaction After 6 hours, take it out and let it cool naturally, disperse the obtained product in distilled water, wash twice, dry at 35°C, pulverize and pass through a 50-mesh sieve to obtain the required Dalily powder.

Embodiment 2

[0025] Harvest the big lily bulbs, peel off the scales, wash 3 times to remove the sediment, filter out the water, add 3 times the weight of water for beating treatment, filter through a 100-mesh sieve, collect the filtrate for concentration, and concentrate to 4 / 15 of the weight of the filtrate. The concentrated solution is mixed with lysine, the mass ratio of lysine and Dalily flakes is 1:15, the pH is adjusted to 8 with a 3% sodium hydroxide solution, and left for 13 minutes. Add 50% mass concentration of citric acid aqueous solution, the weight ratio of citric acid contained in the citric acid aqueous solution to dalilia scales is 1:4, mix and stand for 4 hours and then dry at 35°C for 8 hours; place the obtained dried product in an oven at 140°C for reaction After 4 hours, take it out and let it cool naturally, disperse the obtained product in distilled water, wash twice, dry at 38° C., and pulverize through a 70-mesh sieve to obtain the desired lily powder.

Embodiment 3

[0027] Harvest the big lily bulbs, peel off the scales, wash 4 times to remove the sediment, filter out the water, add 2 times the weight of water for beating treatment, filter through a 100-mesh sieve, collect the filtrate for concentration, and concentrate to 1 / 3 of the weight of the filtrate. The concentrated solution was mixed with lysine, the mass ratio of lysine and Dalily flakes was 1:20, the pH was adjusted to 9 with 5% sodium hydroxide solution, and left for 15 minutes. Add 60% mass concentration of citric acid aqueous solution, the weight ratio of citric acid contained in the citric acid aqueous solution to dalilia scales is 1:5, mix and stand for 5 hours and then dry at 40°C for 7 hours; place the obtained dried product in an oven at 150°C for reaction After 2 hours, take it out and let it cool naturally, disperse the obtained product in distilled water, wash twice, dry at 45° C., and pulverize through a 100-mesh sieve to obtain the desired lily powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com