A kind of copper oxide ore flotation method

A technology of copper oxide ore and raw ore, which is applied in the field of mineral processing and mineral processing, can solve the problems of long process, large consumption of leaching agent, and inconspicuous effect, and achieve the effect of high product grade and improved copper recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

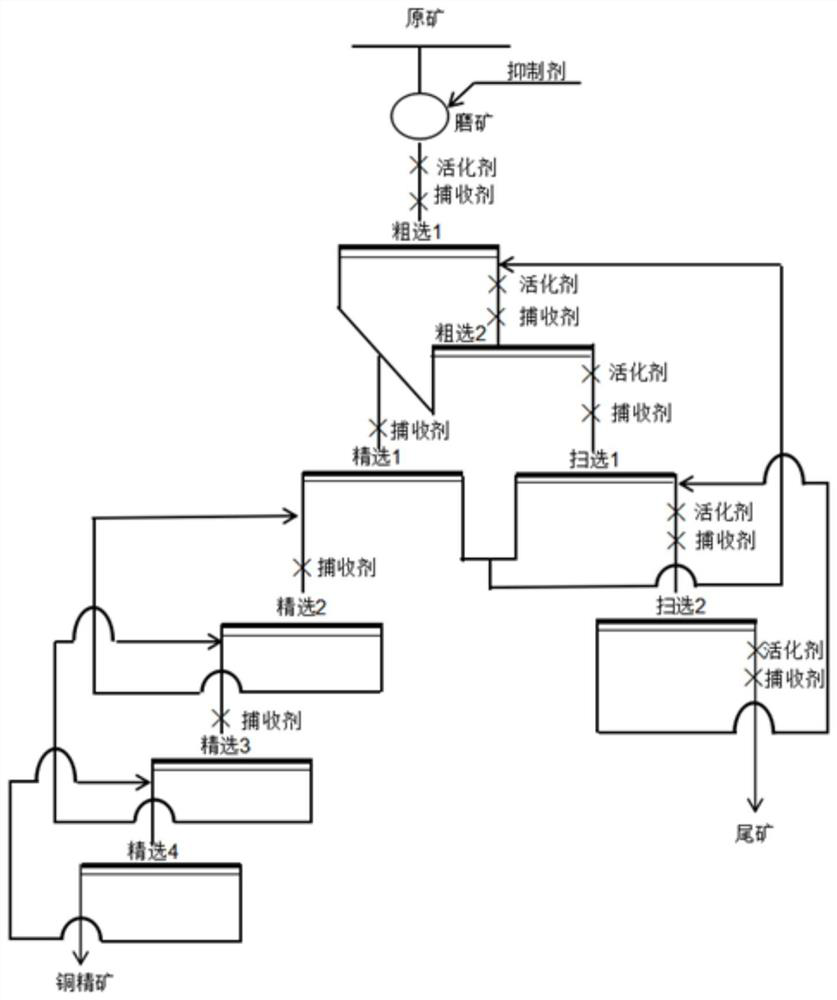

[0048] use figure 1 The process flow shown is to carry out flotation treatment on a copper oxide mine in Yunnan, as follows.

[0049]The copper oxide ore sample was taken from a copper oxide mine in Yunnan. The raw ore contained 1.5% copper, and copper existed as free copper oxide and bound copper oxide, of which bound copper oxide accounted for 8.6%. The mineral is ball milled by adding 500g / t water glass in advance to obtain a floatable slurry with a monomer dissociation degree greater than 90%;

[0050] Floatable pulp has undergone 2 times of roughing, 2 times of sweeping and 4 times of beneficiation:

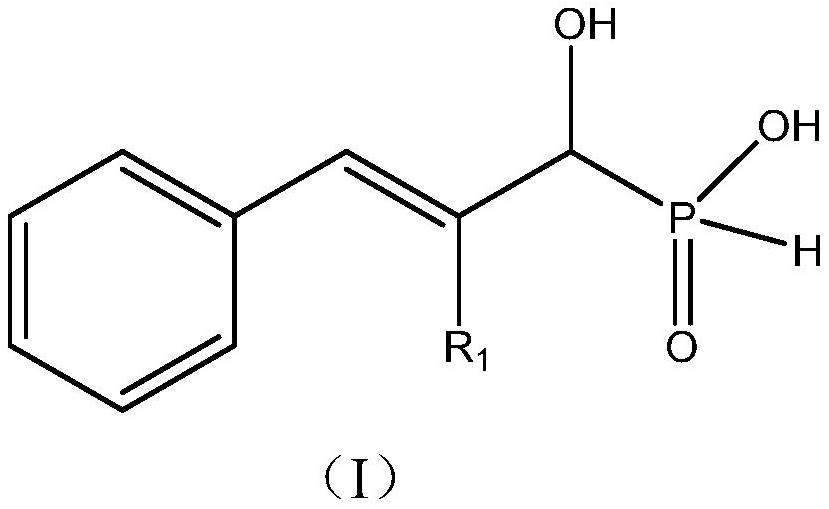

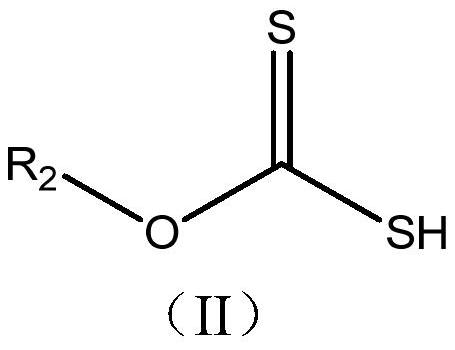

[0051] Rough selection 1. Add 400g / t of ammonium sulfide, 300g / t of α-hydroxyphenylpropenylphosphonous acid and 150g / t of hexyl xanthate,

[0052] Add 300g / t of ammonium sulfide, 200g / t of α-hydroxyphenylpropenyl phosphonous acid and 100g / t of hexyl xanthate to roughing two;

[0053] Add 100g / t of ammonium sulfide, 50g / t of α-hydroxyphenylpropenyl phosphonous acid and 25g...

Embodiment 2

[0062] use figure 1 The process flow shown is to carry out flotation treatment on a copper oxide mine in Xinjiang, as follows.

[0063] The copper oxide ore sample was taken from a copper oxide mine in Xinjiang. The raw ore contained 2.11% copper, and copper existed as free copper oxide and bound copper oxide, of which bound copper oxide accounted for 5.8%. The mineral is ball milled by adding 750g / t water glass in advance to obtain a floatable slurry with a monomer dissociation degree greater than 90%;

[0064] Floatable pulp has undergone 2 times of roughing, 2 times of sweeping and 4 times of beneficiation:

[0065] Rough selection 1. Add 400g / t of ammonium sulfide, 250g / t of α-hydroxy-2-methyl-3-phenylpropenylphosphonous acid and 250g / t of butyl xanthate,

[0066] Add 300g / t of ammonium sulfide, 200g / t of α-hydroxy-2-methyl-3-phenylpropenylphosphonous acid and 200g / t of butyl xanthate in roughing two;

[0067] Add 100g / t of ammonium sulfide, 100g / t of α-hydroxy-2-methyl...

Embodiment 3

[0076] use figure 1 The process flow shown is to carry out flotation treatment on a copper oxide mine in Hubei, as follows.

[0077] The copper oxide ore sample was taken from a copper oxide mine in Hubei. The raw ore contained 0.65% copper, and copper existed as free copper oxide and bound copper oxide, of which bound copper oxide accounted for 10.8%. The mineral is ball milled by adding 1000g / t water glass in advance to obtain a floatable slurry with a monomer dissociation degree greater than 90%;

[0078] Floatable pulp has undergone 2 times of roughing, 2 times of sweeping and 4 times of beneficiation:

[0079] After roughing, add 400g / t of ammonium sulfide, 300g / t of ethyl xanthate and 300g / t of α-hydroxy-2-ethyl-3-phenylpropenylphosphonous acid,

[0080] Add 300g / t of ammonium sulfide, 200g / t of ethyl xanthate and 200g / t of α-hydroxy-2-ethyl-3-phenylpropenyl phosphonous acid in roughing two;

[0081] Add 100g / t of ammonium sulfide, 50g / t of ethyl xanthate and 50g / t of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com