Frost-resistant high-performance concrete and preparation method thereof

A technology of high-performance concrete and frost resistance, applied in the field of concrete, can solve problems affecting other strength of concrete, large expansion of concrete, corrosion of steel bars, etc., and achieve the effect of improving frost resistance, strength, and frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

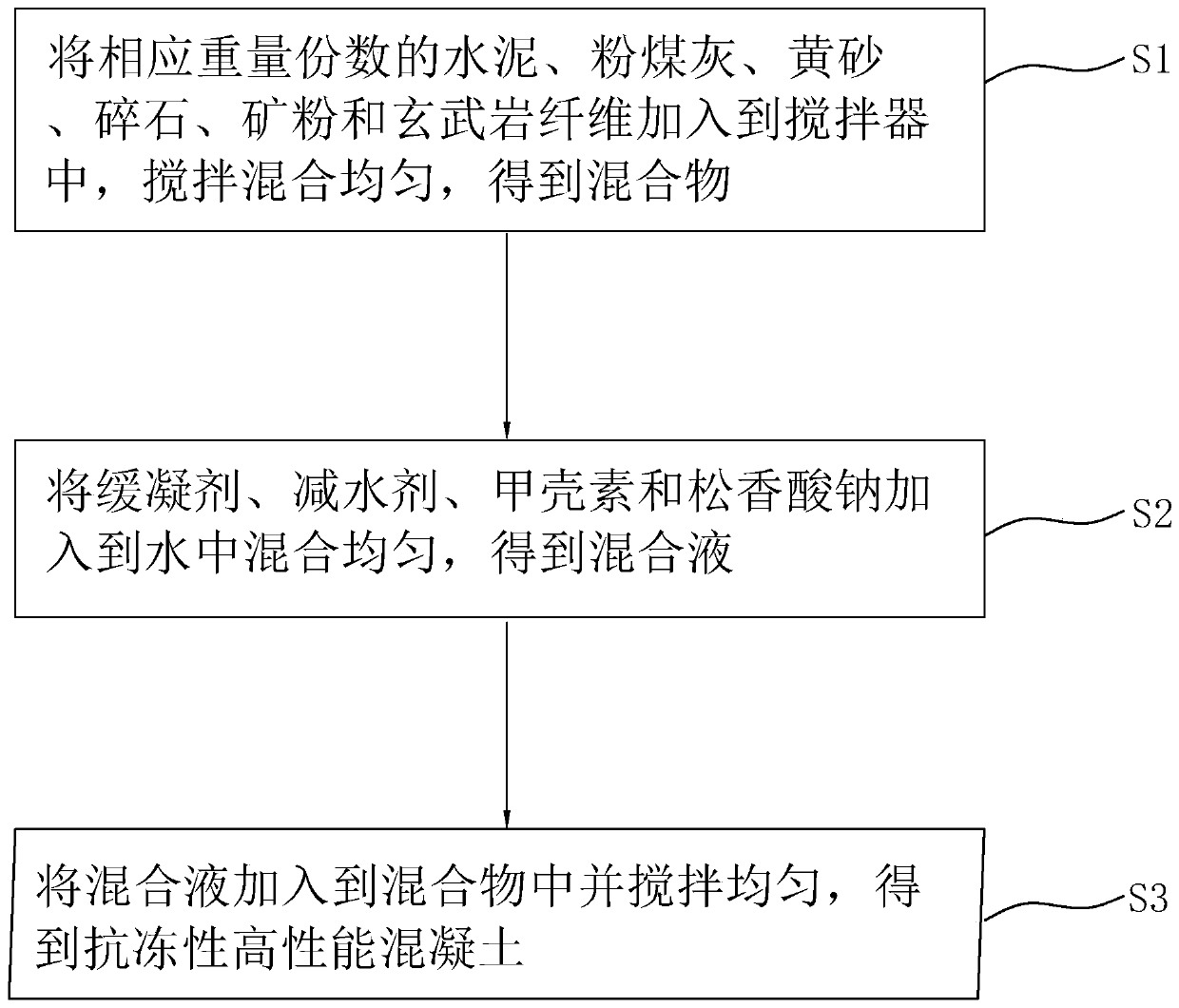

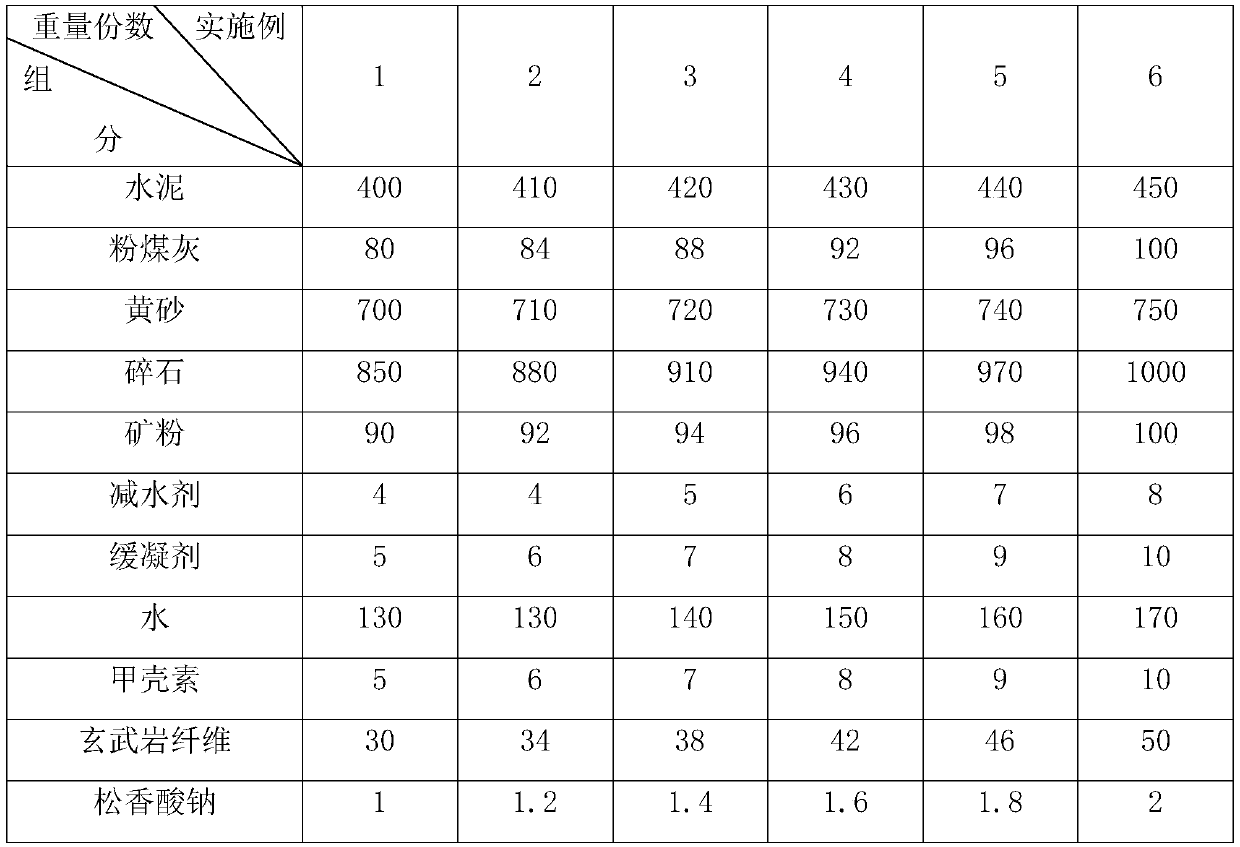

[0055] Embodiment 1: as figure 1 As shown, a kind of frost-resistant high-performance concrete and its preparation method, each component and its corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0056] S1, adding cement, fly ash, yellow sand, crushed stone, slag powder and basalt fiber into the agitator tank in corresponding parts by weight, and stirring for 6 minutes at 500 rpm to form a mixture;

[0057] S2, adding retarder, water reducer, chitin and sodium rosinate into water and mixing evenly, stirring at 800 rpm for 5 minutes to obtain a mixed solution;

[0058] S3, adding the mixed solution into the mixture and stirring evenly, and continuously stirring and mixing at 600 rpm for 8 minutes to obtain frost-resistant high-performance concrete.

[0059] In this embodiment, the diameter of the basalt fiber is 10 μm and the length is 5 mm.

Embodiment 2-6

[0060] Example 2-6: A frost-resistant high-performance concrete and its preparation method. The difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0061] Each component and parts by weight thereof in table 1 embodiment 1-6

[0062]

Embodiment 7

[0063] Example 7: A frost-resistant high-performance concrete and its preparation method. The difference from Example 1 is that the diameter of the basalt fiber in this example is 12 μm and the length is 8 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com