Bus connecting device and inflatable ring main unit performance test system and method based on bus connecting device

A technology of bus bar connection and inflatable ring, which is applied in the direction of measuring device, measuring device casing, measuring electricity, etc., can solve the problems of low test efficiency, inaccurate test results, and affecting the performance of inflatable ring main unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

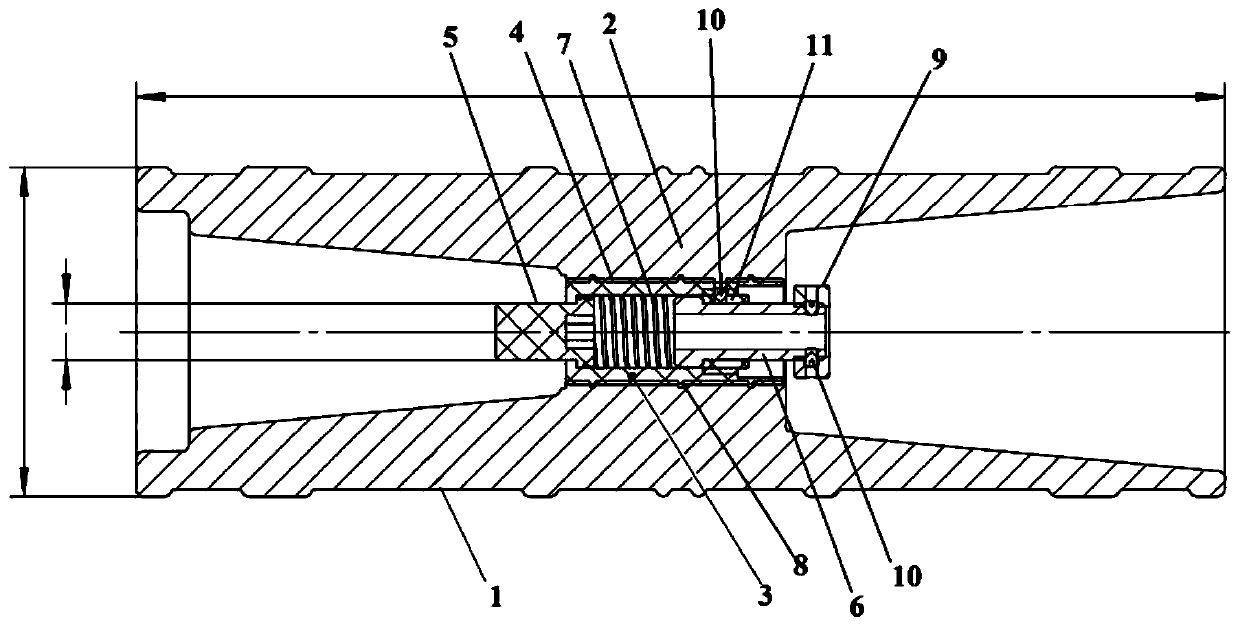

[0022] see figure 1 , the bus connection device includes an insulating envelope 1 with both ends open; the middle part of the inner cavity of the insulating envelope 1 is provided with a blocking member 2 that blocks the inner cavity; The fitting assembly 3; the fitting assembly 3 includes a copper pipe 4, one end of the copper pipe 4 is fixed with a static contact 5, and the other end of the copper pipe 4 is provided with a moving contact 6, and the static contact 5 and the moving contact 6 are connected by a spring 7 arranged in the inner cavity of the copper tube 4 .

[0023] Wherein, the outer wall of the copper pipe 4 is provided with a positioning ring 8 . The surface of the barrier member 2 in contact with the copper pipe 4 is provided with a concave ring that fits with the positioning ring 8 . The end of the moving contact 6 is provided with a moving contact disc 9 . The movable contact plate 9 is fixed on the end of the movable contact 6 by fastening screws 10 . T...

Embodiment 2

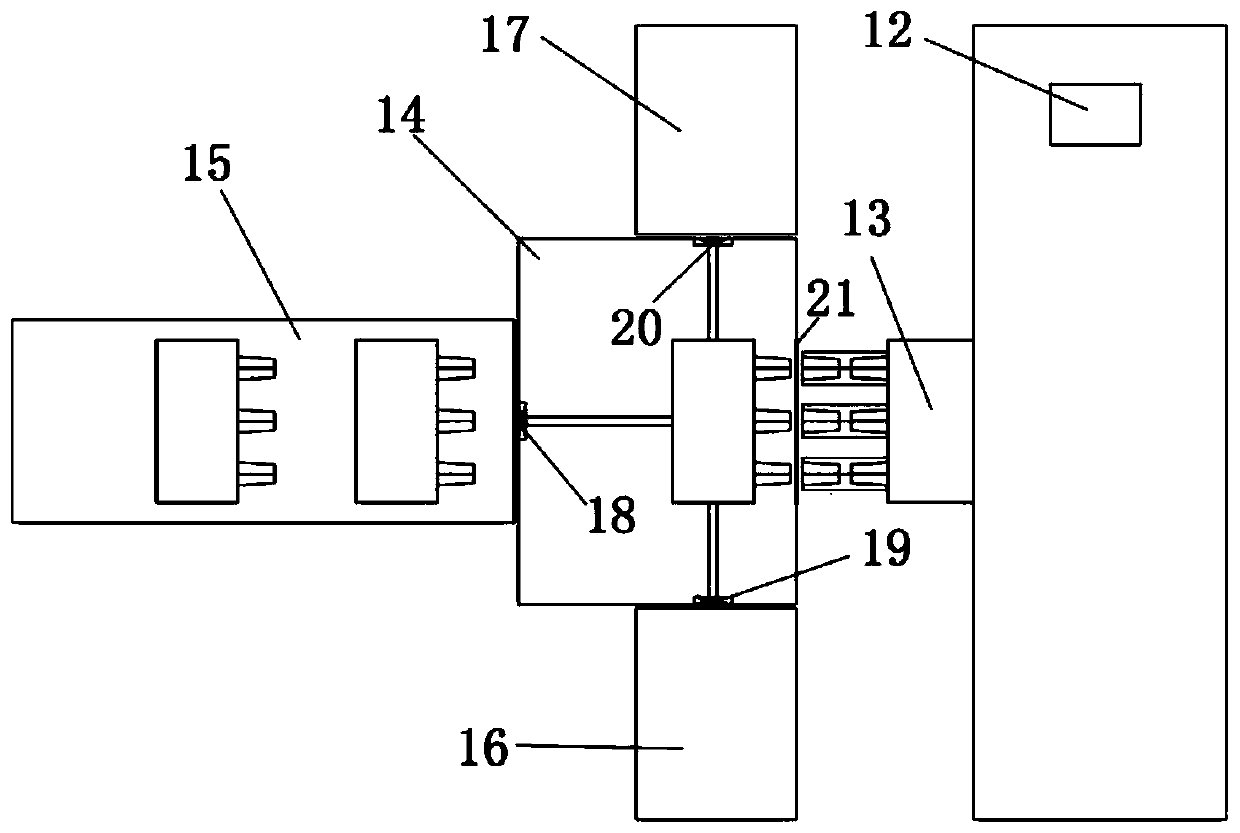

[0025] The performance testing system of the inflatable ring network cabinet includes an operating platform 12 and a test platform 13 connected to the operating platform 12; the outlet casing of the test platform 13 is connected to the static contact of the above-mentioned busbar connection device through the inner concave thread at the end. External thread fastening connection; the performance testing system of the inflatable ring network cabinet also includes a test station 14, and the sampling end of the test station 14 is connected with the conveyor belt 15 of the inflatable ring network cabinet to be tested, and the test station 14 One side is connected with qualified product conveyor belt 16, and the other side is connected with non-qualified product conveyor belt 17; The sampling end of described test station 14 is provided with to-be-tested inflatable ring network cabinet pushing mechanism 18; Described test station 14 An end near the qualified product conveyor belt 16 ...

Embodiment 3

[0027] The inflatable ring main unit performance test method based on the above-mentioned inflatable ring main unit performance testing system is to transport the inflatable ring main unit to be tested to the test station 14 through the inflatable ring main unit conveyor belt 15 to be tested; The ring network cabinet pushing mechanism 18 transports the inflatable ring network cabinet to be tested to the positioning platform 21, and when the wall of the inflatable ring network cabinet to be tested contacts the positioning platform 21, the outlet sleeve of the inflatable ring network cabinet to be tested extends into the bus connection device. The open end pushes the moving contact 6 to compress the spring 7 between the moving contact 6 and the static contact 5, and the operating platform 12 controls the testing platform 13 to start the electrical performance test; after the test is completed, the operating platform 12 issues a control command, When the inflatable ring network ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com