Slow-release chlorine dioxide disinfectant and preparation method thereof

A chlorine dioxide and disinfectant technology, applied in the direction of disinfectants, chemical instruments and methods, botany equipment and methods, etc., can solve the problems of easy volatilization of solutions, difficult transportation and storage, unstable performance, etc., and achieve improved thermal stability Sexuality, controllable release speed, low efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In one embodiment, the preparation method of the starch-grafted polyacrylamide comprises the steps of:

[0037] (1) Mix starch, acrylamide, N,N-methylenebisacrylamide and distilled water, and keep the speed of the internal mixer at 70-100r / min in the chamber of the internal mixer at 70-90°C to fully paste Starch and homogenize the mixed reactant for 5-10min;

[0038] (2) Lower the chamber temperature of the internal mixer to 25-35°C, add the newly prepared ammonium persulfate aqueous solution, and mix quickly at 80-120r / min for 1-3min to obtain the starch-grafted polypropylene amides;

[0039] In the step (1), the mass ratio of the starch, acrylamide, N,N-methylenebisacrylamide and distilled water is 2:1:0.02:4.5;

[0040] In the step (2), the concentration of the ammonium persulfate aqueous solution is 0.03g / mL, and the volume is 5mL.

[0041] In a preferred embodiment, the preparation method of the starch-grafted polyacrylamide comprises the steps of:

[0042] (1)...

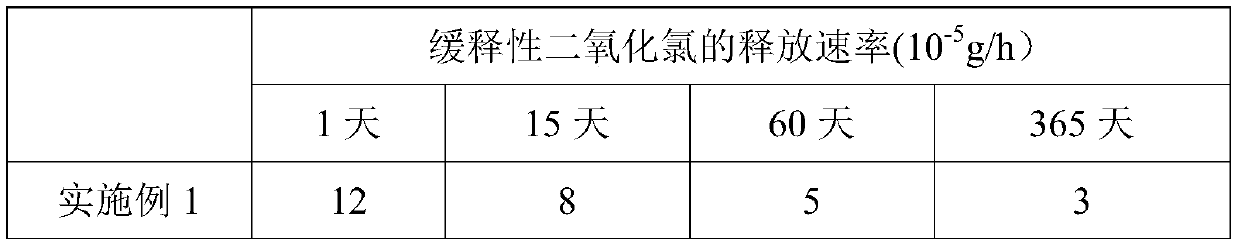

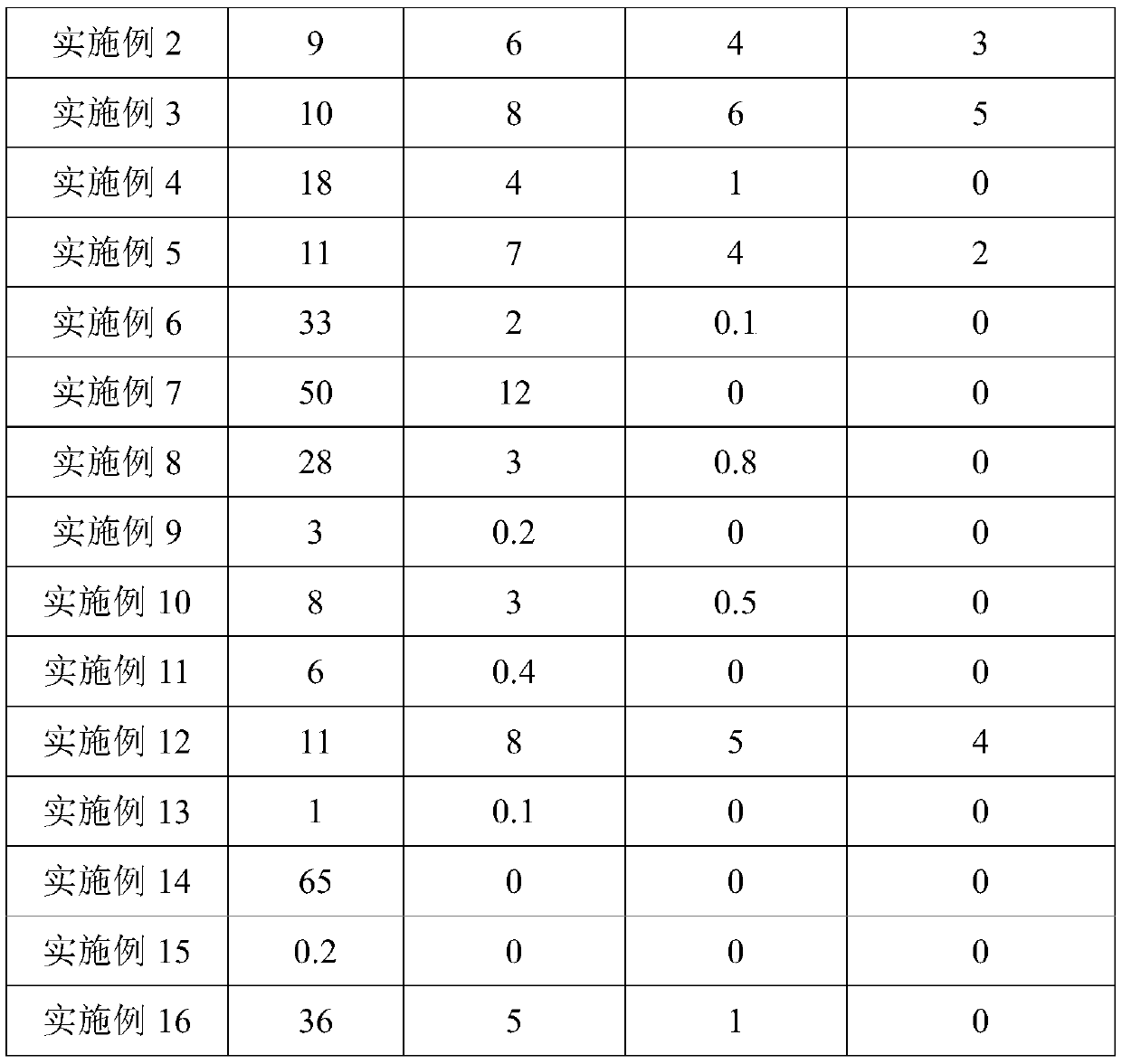

Embodiment 1

[0122] Embodiment 1 provides a kind of slow-release chlorine dioxide disinfectant, and described disinfectant comprises slow-release agent and chlorine dioxide generator; The mass ratio of described slow-release agent and chlorine dioxide generator is 2:1; In parts by weight, the chlorine dioxide generator includes 10 parts of chlorite, 10 parts of activator, and 3 parts of filler;

[0123] The slow-release agent includes a polymer coating agent and an inorganic slow-release agent; the mass ratio of the polymer coating agent and the inorganic slow-release agent is 1:11;

[0124] The inner layer of the polymer coating agent is a water-retaining polymer material, and the outer layer is a water-insoluble or insoluble polymer material; the polymer coating agent is provided with an opening agent; the opening agent is hydroxyethyl fiber element; the mass ratio of the water-retaining polymer material, water-insoluble or insoluble polymer material, and hydroxyethyl cellulose is 3:1:0....

Embodiment 2

[0157] Embodiment 2 provides a kind of slow-release chlorine dioxide disinfectant, and described disinfectant comprises slow-release agent and chlorine dioxide generator; The mass ratio of described slow-release agent and chlorine dioxide generator is 3:1; In parts by weight, the chlorine dioxide generator includes 20 parts of chlorite, 15 parts of activator, and 6 parts of filler;

[0158] The slow-release agent includes a polymer coating agent and an inorganic slow-release agent; the mass ratio of the polymer coating agent and the inorganic slow-release agent is 1:11;

[0159] The inner layer of the polymer coating agent is a water-retaining polymer material, and the outer layer is a water-insoluble or insoluble polymer material; the polymer coating agent is provided with an opening agent; the opening agent is hydroxyethyl fiber element; the mass ratio of the water-retaining polymer material, water-insoluble or insoluble polymer material, and hydroxyethyl cellulose is 3.5:1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com