Comprehensive utilization method of aluminum-containing waste acid

A technology for waste acid and aluminum waste, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve unspecified problems, achieve the effect of reducing addition and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

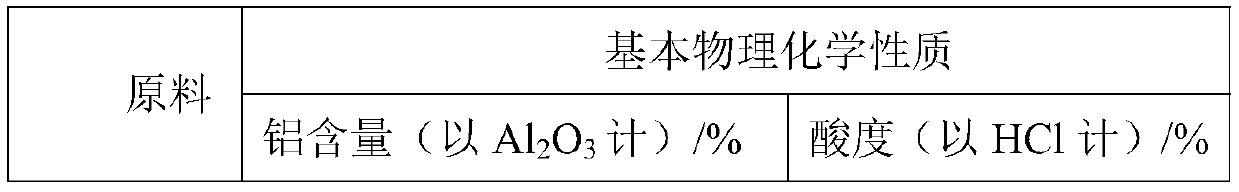

[0029] The aluminum-containing waste acid of the present embodiment is aluminum-containing waste hydrochloric acid, specifically as follows:

[0030]

[0031]

[0032] A method for comprehensive utilization of aluminum-containing waste acid, comprising the steps of:

[0033] 1) 5t of aluminum-containing waste acid is treated with 100-mesh precision filtration, and the flow rate is controlled at 1t / h. After being pumped into the filter, it enters the special separation membrane module. The special separation membrane is an acid and alkali resistant NF membrane;

[0034] 2) Slowly adjust the booster valve, slowly increase the pressure to 4Mpa, observe the liquid level gauge at the water production end rise slowly, gradually pressurize to 4.5Mpa, record the flow rate at the water production end as 550L / h, and the water production enters the reuse pool;

[0035] 3) In order to ensure that the flow rate of the produced water end is maintained at 400-500L / h, the operating pres...

Embodiment 2

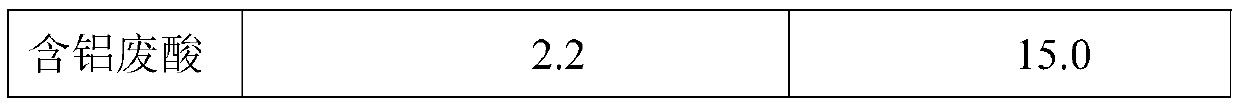

[0040] The aluminum-containing waste acid of the present embodiment is aluminum-containing waste phosphoric acid, specifically as follows:

[0041]

[0042] A method for comprehensive utilization of aluminum-containing waste acid, comprising the steps of:

[0043] 1) 5t of aluminum-containing waste acid is treated with 100-mesh precision filtration, and the flow rate is controlled at 1t / h. After being pumped into the filter, it enters the special separation membrane module. The special separation membrane is an acid and alkali resistant NF membrane;

[0044] 2) Slowly adjust the booster valve, slowly increase the pressure by 2Mpa, observe the liquid level gauge at the water production end rise slowly, gradually pressurize to 3Mpa, record the flow rate at the water production end as 560L / h, and the water production enters the reuse pool;

[0045] 3) In order to ensure that the flow rate of the produced water end is maintained at 500L / h, the operating pressure is constantly a...

Embodiment 3

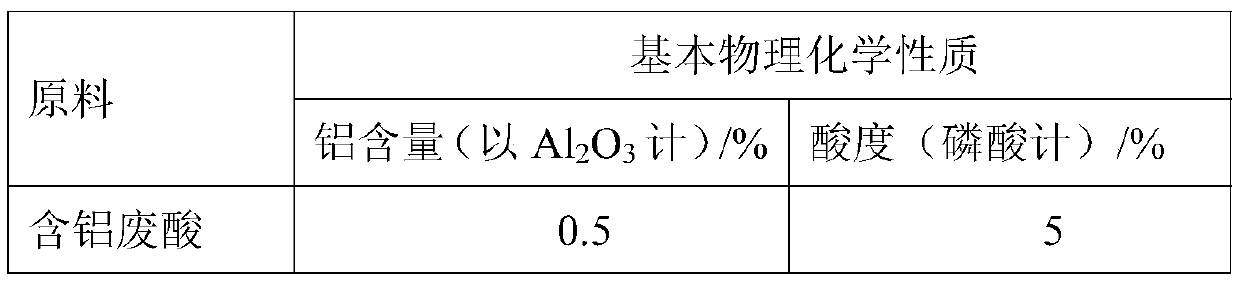

[0050] The aluminum-containing waste acid of the present embodiment is aluminum-containing waste sulfuric acid, specifically as follows:

[0051]

[0052] A method for comprehensive utilization of aluminum-containing waste acid, comprising the steps of:

[0053] 1) 5t of aluminum-containing waste acid is treated with 100-mesh precision filtration, and the flow rate is controlled at 1t / h. After being pumped into the filter, it enters the special separation membrane module. The special separation membrane is an acid and alkali resistant NF membrane;

[0054] 2) Slowly adjust the booster valve, slowly increase the pressure to 4Mpa, observe the liquid level gauge at the water production end rise slowly, gradually pressurize to 6Mpa, record the flow rate at the water production end as 540L / h, and the water production enters the reuse pool;

[0055] 3) In order to ensure that the flow rate of the produced water end is maintained at 500L / h, the operating pressure is constantly adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com