HDPE pipes and fittings

A high-density polyethylene and low-density polyethylene technology, which is applied in the direction of pipes/pipe joints/fittings, pipe connection arrangements, pipes, etc., can solve the problems of high-density polyethylene deterioration and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0170] Hereinafter, although an Example is shown and this invention is demonstrated concretely, the technical scope of this invention is not limited to this.

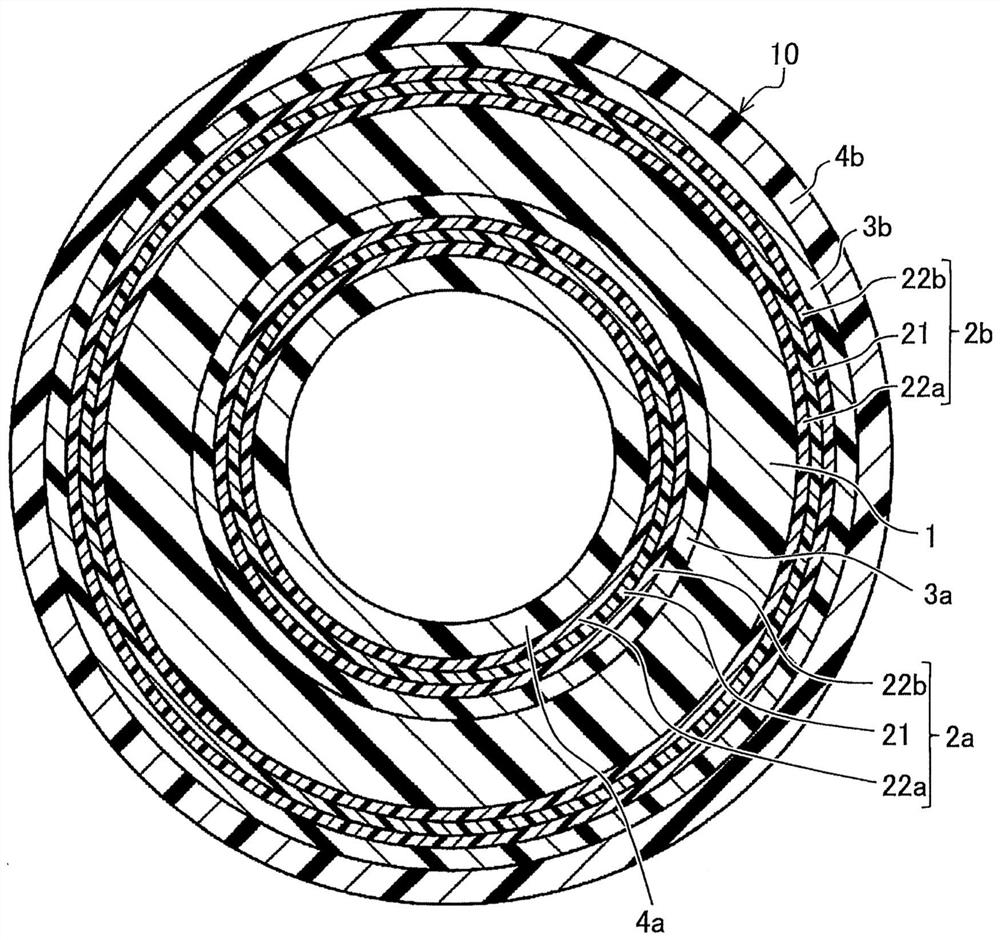

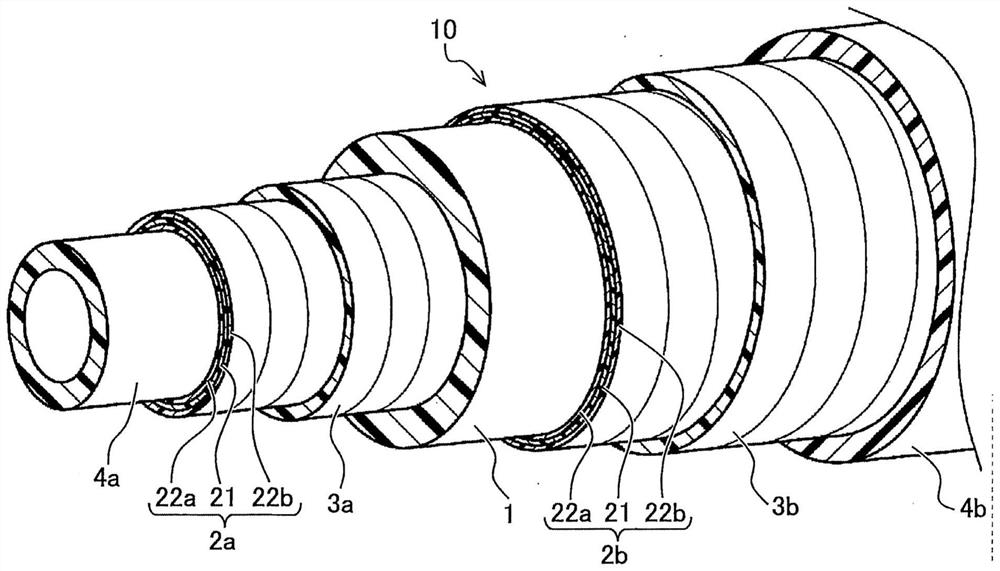

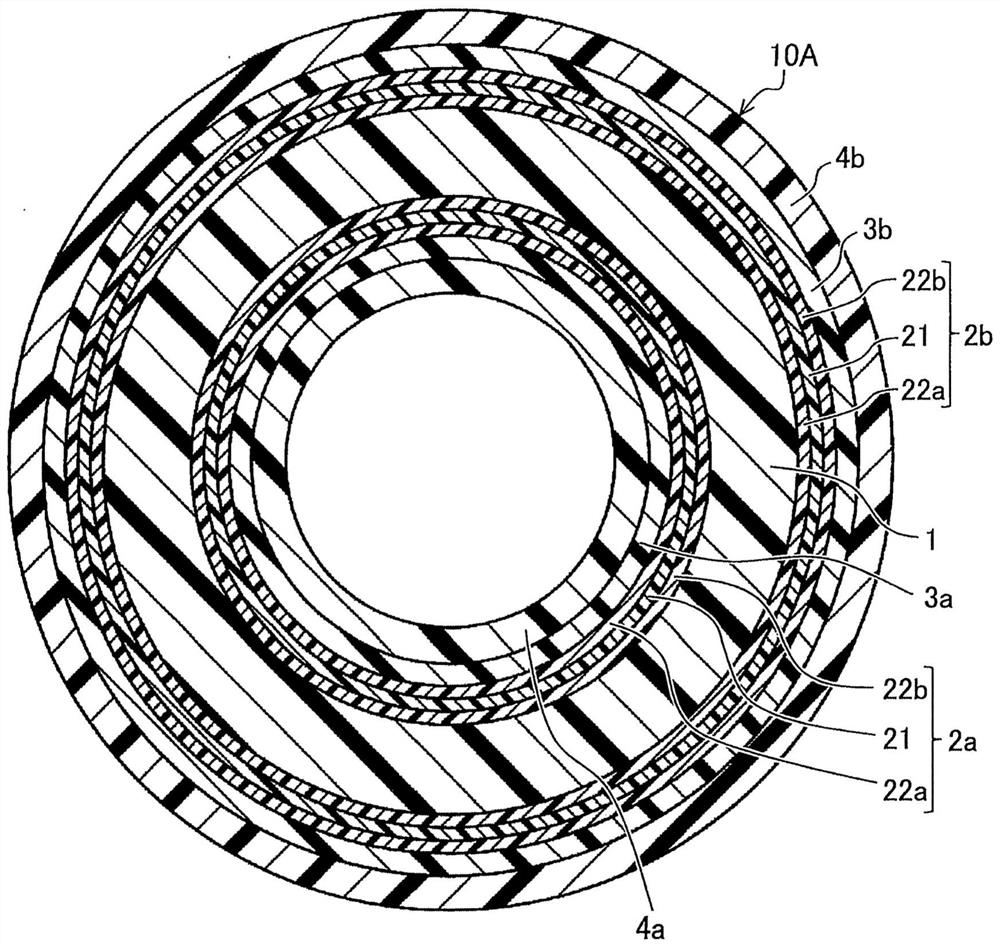

[0171] Test pieces of high-density polyethylene pipes were prepared by varying the addition amount of naphthene-containing oil and aromatic hydrocarbon-containing oil, and the layer configuration of the gas barrier film, and the tensile elongation at break after radiation exposure treatment was evaluated.

[0172] As the conduit, high-density polyethylene produced using a Ziegler catalyst was used. In the base material of high-density polyethylene, as an additive, mix naphthenic oil or oil containing aromatic hydrocarbons, use a Banbury mixer, knead at 180°C for 10 minutes, and granulate high-density polyethylene pipes. particles. Then, the pellets were charged into an injection molding machine to mold a cylindrical catheter.

[0173] Next, using a winding machine, the gas barrier film is wound only on the outer perip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com