A Vertical Flow Constructed Wetland Structure and Configuration Method for Improving Electric Energy Capture During Sewage Purification

A technology for artificial wetland and sewage purification, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of non-conductive filler matrix without breakthrough, decreased Coulombic efficiency, and increased internal resistance and other issues to achieve the effect of improving the electron capture ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]A method for improving the vertical flow constructed wetland configuration of electric energy capture in the sewage purification process, the steps are as follows:

[0037] A. Sewage enters continuously from the bottom of the system and distributes water evenly, and then rises in push flow along the non-conductive filler layer 1 at the bottom. Under the adsorption, retention and oxidation of fillers and microorganisms in this layer, most of the oxygen in the sewage is consumed;

[0038] B. The sewage after step A flows into the anode conductive filler layer 2, the growth and enrichment of the electrogenic bacteria group is promoted in an anaerobic environment and electrons are generated, and the electrons flow out through the anode collector through the outer wire 8, and pass through the outer wire 8 and the load 9 Then flow into the cathode collector 7;

[0039] C, then the sewage flows into the non-conductive filler isolation layer 3, the main function of the non-condu...

Embodiment 2

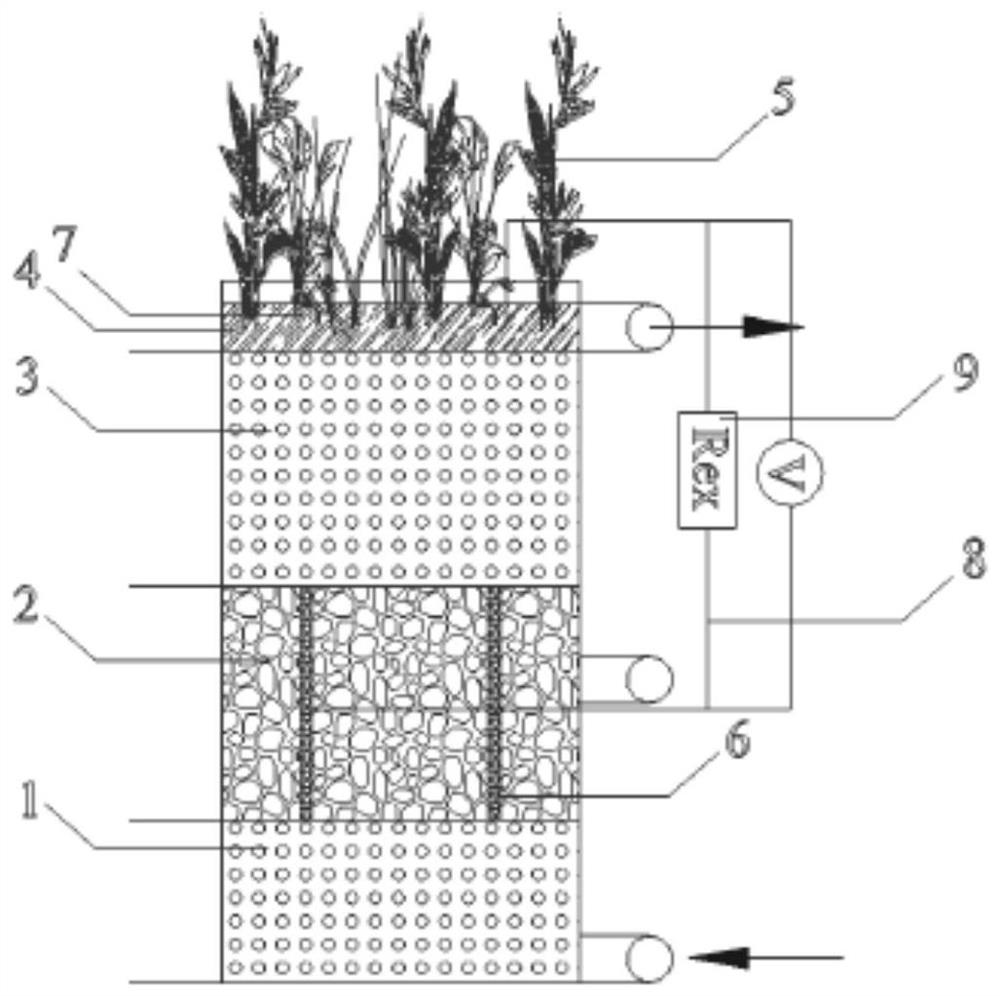

[0047] A vertical flow artificial wetland structure that improves electrical energy capture in the process of sewage purification. This configuration is laid from bottom to top with a bottom non-conductive filler layer 1, an anode conductive filler layer 2; a non-conductive filler isolation layer 3; a cathode conductive filler layer 4; It is characterized in that: the anode conductive filler layer 2 is connected to the bottom non-conductive filler layer 1 and the non-conductive filler isolation layer 3 respectively, the cathode conductive filler layer 4 is connected to the non-conductive filler isolation layer 3, and in the non-conductive filler isolation layer 3 Wetland plants 5 are planted, the anode collector 6 and the cathode collector 7 are connected by an outer wire 8, the anode collector 6 and the cathode collector 7 are respectively placed in the anode conductive filler layer 2 and the cathode conductive filler layer 4, and the anode collector 6 One end and one end of t...

Embodiment 3

[0063] A method of vertical flow constructed wetland configuration to improve electrical energy capture in sewage purification process, the implementation process is:

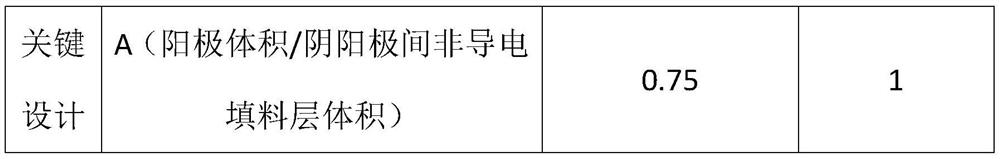

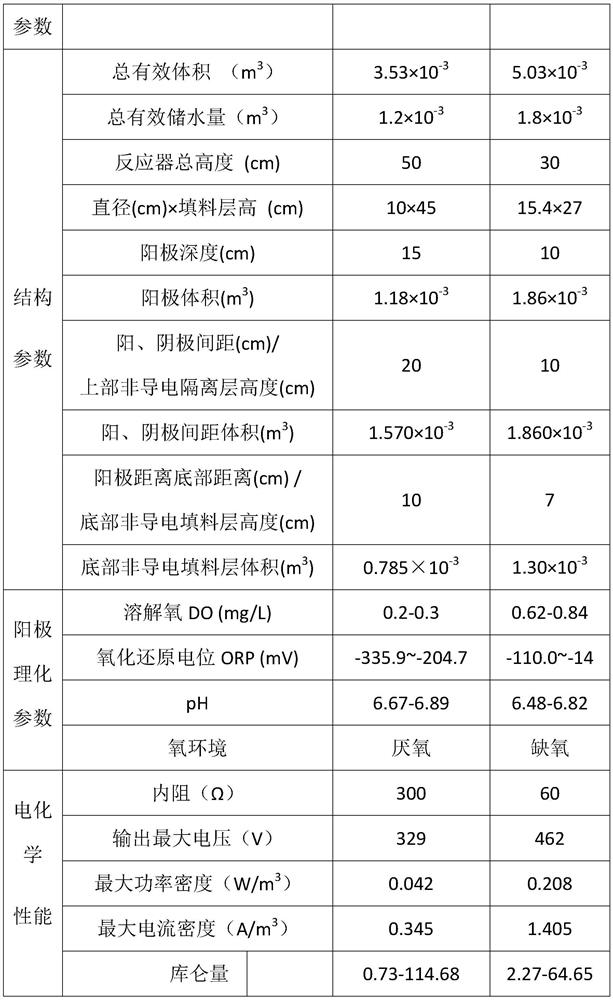

[0064] For the comprehensive sewage of COD=0-1000mg / L concentration scope, adopt the structure among the present invention, compare the electrochemical performance of CW-MFC system under different A values, the result is as shown in table 1: relative to A=0.75, A= 1, the electrical performance parameters of the system are:

[0065] 1) The maximum output voltage is increased by 40.4% to 1.2 times, the maximum current density is increased by 2.03 times, the maximum power density is increased by 4.26 times, and the internal resistance is reduced by 80%;

[0066] 2) The richness of the dominant electrogenic bacterium Geobacter (Geobacter) enriched at the anode increased by 10.2 times, and the richness of Geothrix (Geothrix) increased by 9.93 times;

[0067] 3) The abundance of the dominant denitrification bacteriu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com