Friction nano-generator and preparation method and application thereof

A nanogenerator and electrode technology, which is applied in triboelectric generators, liquid chemical plating, metal material coating technology, etc. The effect of electric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

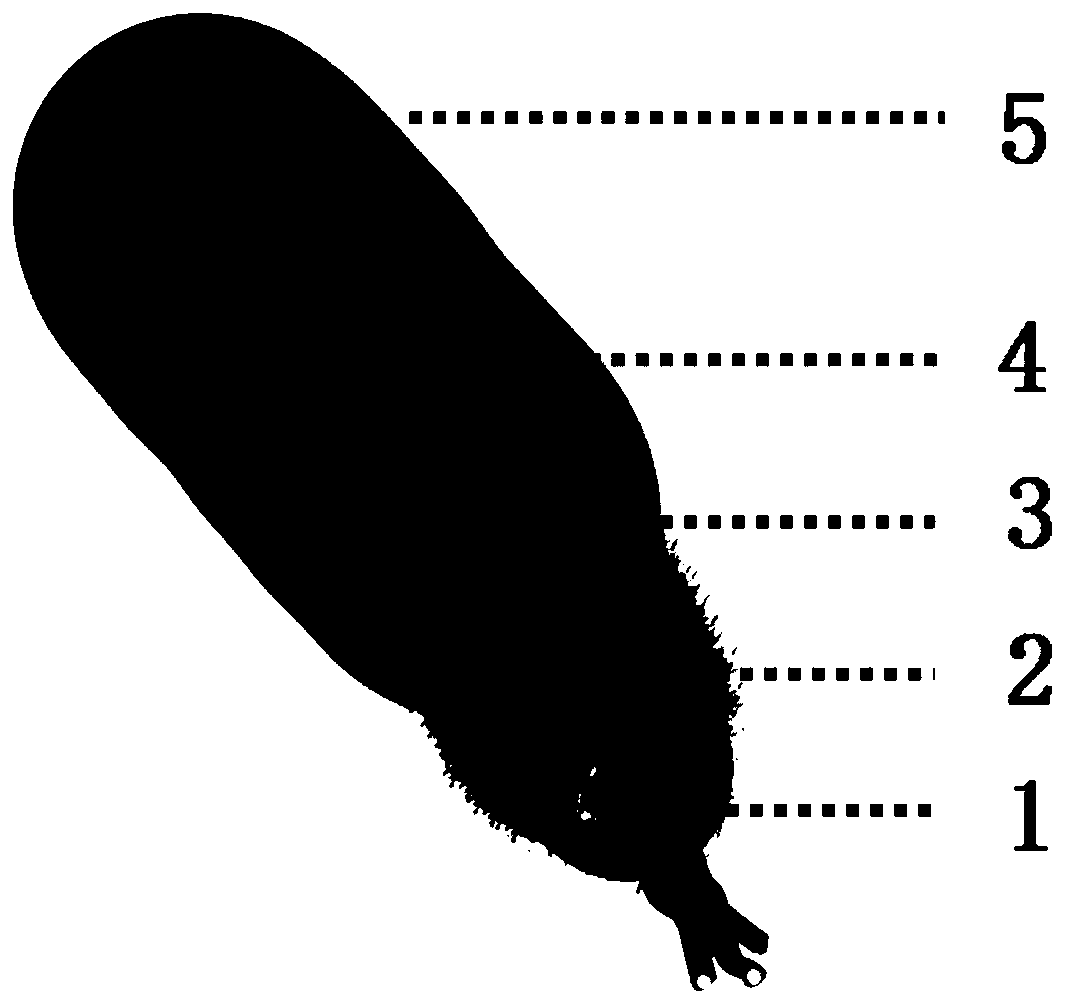

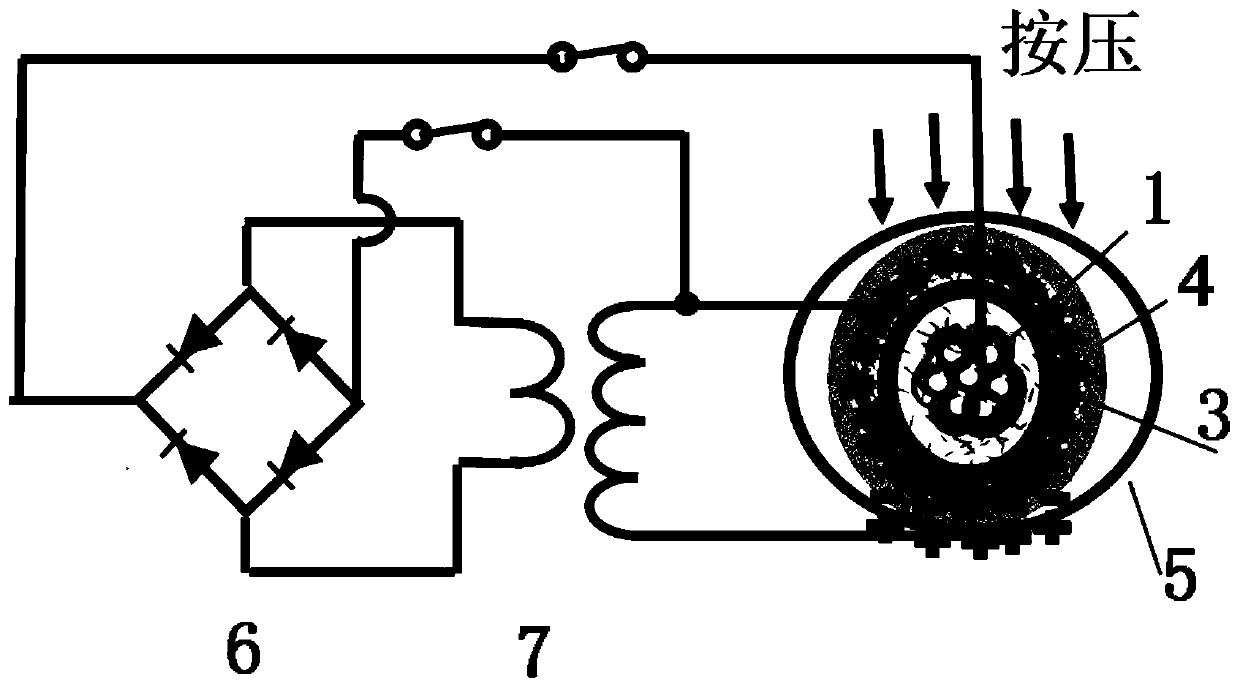

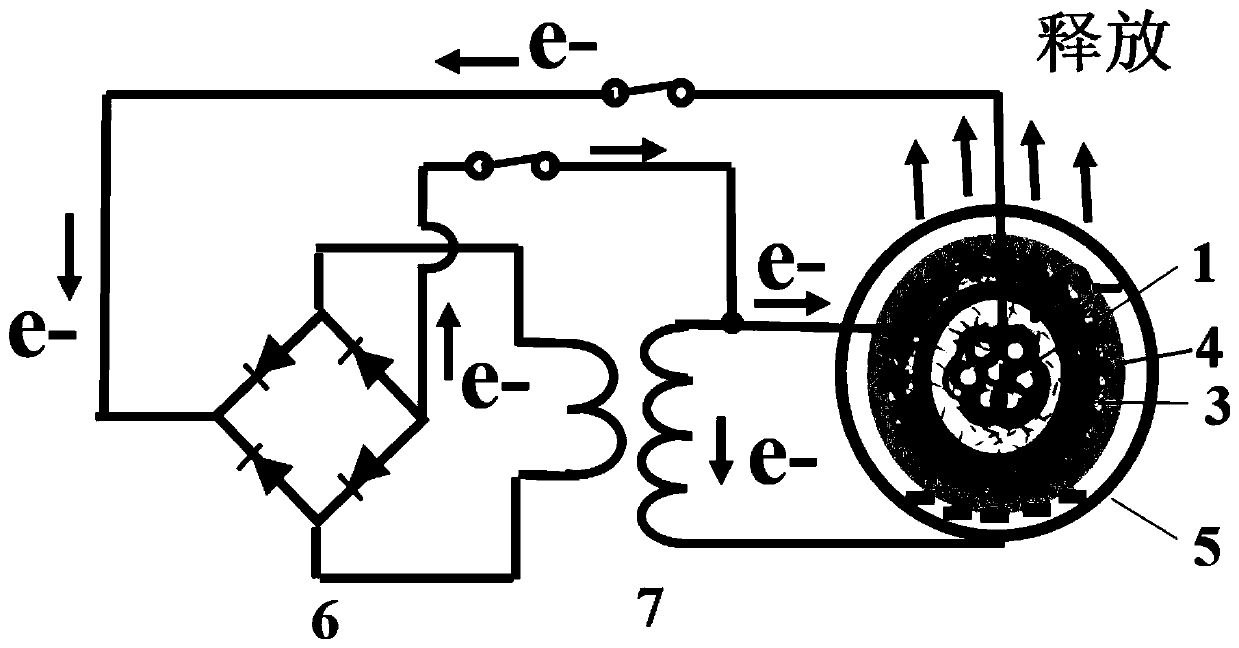

[0072] The structure of the triboelectric nanogenerator provided by this embodiment is as follows: figure 1 shown. The triboelectric nanogenerator provided in this embodiment includes a fibrous capacitor, an interface control layer 4 and a friction electrode 5; the interface control layer 4 is coated on the fibrous capacitor, and the hollow tubular friction electrode 5 is set outside the interface control layer 4 The fibrous capacitor includes a fibrous positive electrode 1, a solid electrolyte 2 covering the fibrous positive electrode 1, and a negative electrode 3 covering the solid electrolyte 2. The distance between the positive electrode 1 and the negative electrode 3 of the fibrous capacitor is 20 μm. In addition, the fibrous positive electrode 1 has the same central axis as the negative electrode 3 as a whole. Generally speaking, the fibrous capacitor, the interface control layer 4 and the friction electrode 5 are all coaxial.

[0073] In the triboelectric nanogenerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com