Sewage treatment system and water treatment process thereof

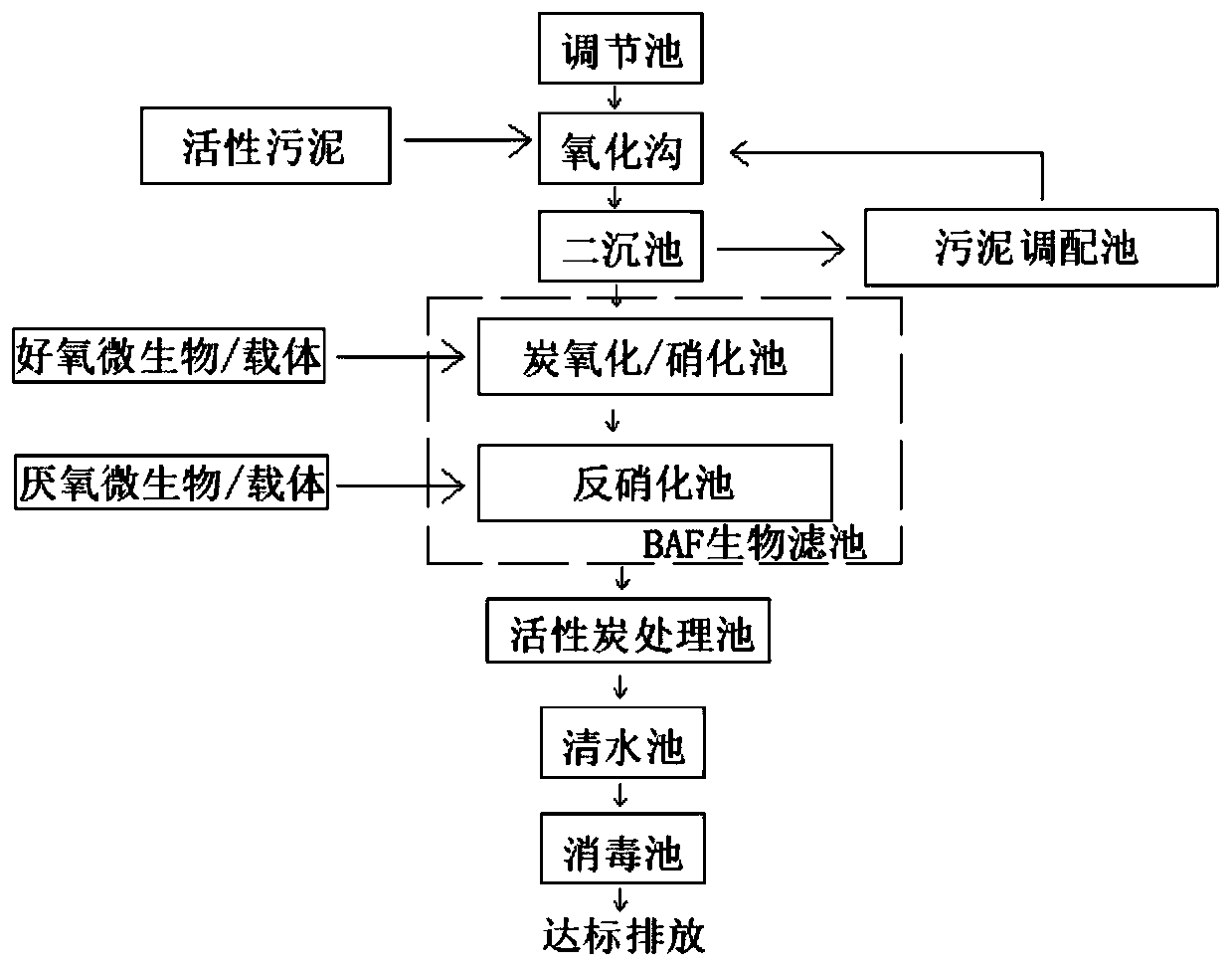

A sewage treatment system and sewage technology, applied in water/sewage treatment, water/sewage multi-stage treatment, biological water/sewage treatment, etc. Removal rate, improved purification effect, better effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

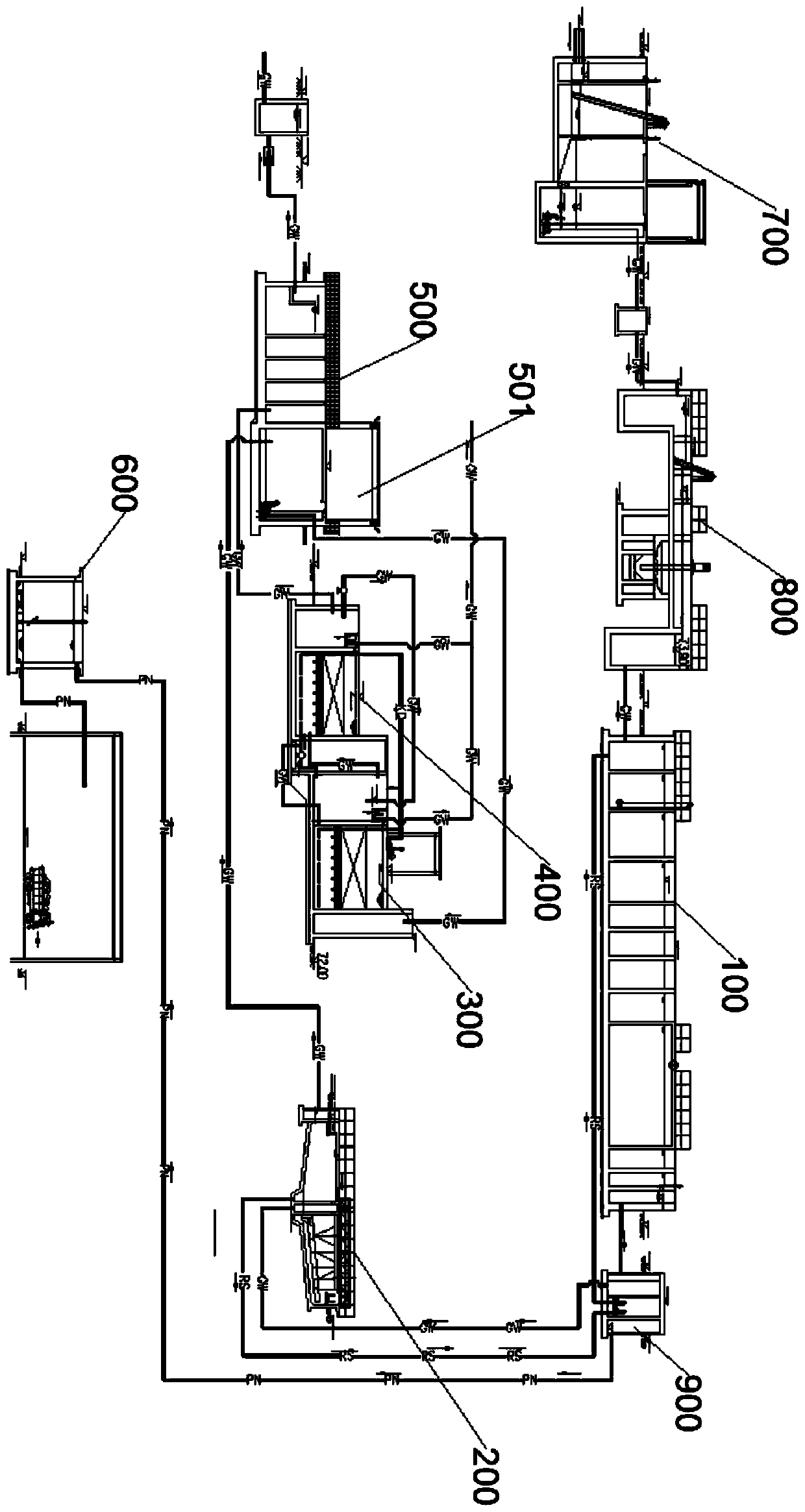

[0057] Step 1: the sewage in the regulating tank 700 enters the oxidation ditch 100 for treatment, and after 12 hours of treatment, the first-grade water is obtained;

[0058] Step 2: the primary water in step 1 enters the secondary sedimentation tank 200, and after precipitation, its supernatant is taken to obtain secondary water;

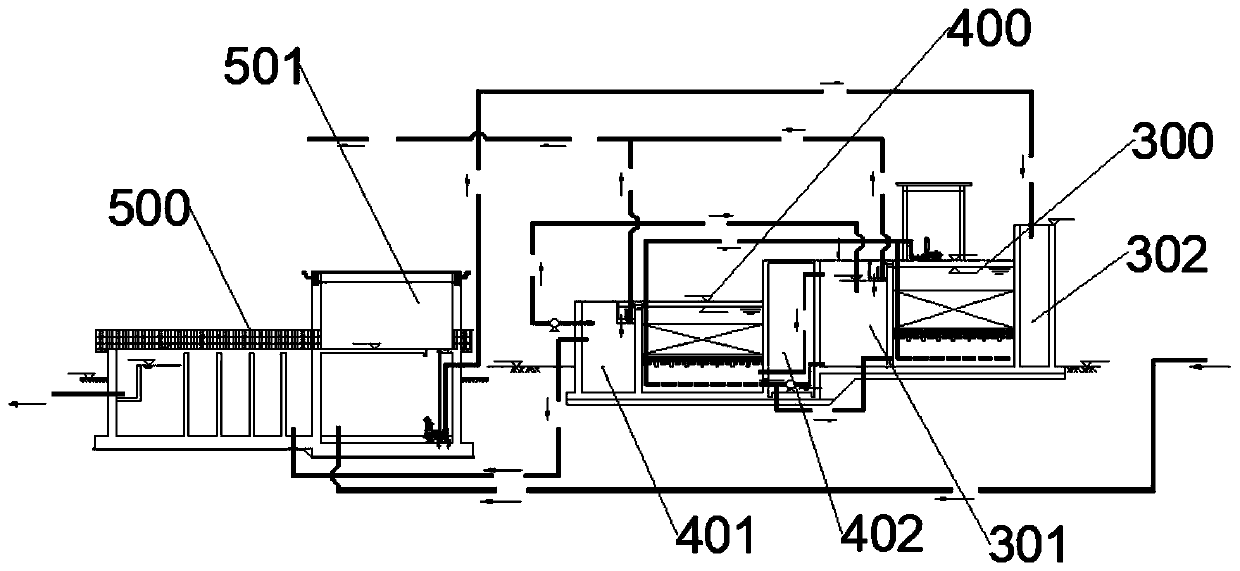

[0059] Step 3: The secondary water in step 2 enters the BAF biofilter for treatment, specifically, the carbon oxidation / nitrification tank 300 and the denitrification tank 400 are equipped with aeration equipment, and the aeration equipment is connected to the fan, wherein Treat in carbon oxidation / nitrification tank 300 for 10h, the gas-water ratio is 10:1, the ammonia nitrogen in the water is carried out nitrification reaction under the effect of aerobic microorganism, gets its supernatant liquid, obtains nitrification water; Backwashing in the air, the backwashing time is 24h, the gas backwashing intensity: 9L / m 2 .s, water backwash intensity:...

Embodiment 2

[0063] Step 1: The sewage in the regulating tank 700 enters the oxidation ditch 100 for treatment, and after 18 hours of treatment, the first-grade water is obtained;

[0064] Step 2: the primary water in step 1 enters the secondary sedimentation tank 200, and after precipitation, its supernatant is taken to obtain secondary water;

[0065] Step 3: The secondary water in step 2 enters the BAF biofilter for treatment, wherein it is treated in the carbon oxidation / nitrification tank 300 for 12 hours, the gas-water ratio is 20:1, and the ammonia nitrogen in the water is under the action of aerobic microorganisms Carry out nitrification reaction, take its supernatant to obtain nitrification water; backwash the nitrification water in a clear water tank, the backwash time is 36h, and the gas backwash intensity: 9L / m 2 .s, water backwash intensity: 4.5L / m 2 .s; then denitrify the backwashed nitrification water in the denitrification tank for 10 hours, the reflux water ratio is 5:1; ...

Embodiment 3

[0069] Step 1: the sewage in the regulating tank 700 enters the oxidation ditch 100 for treatment, and after 20 hours of treatment, first-grade water is obtained;

[0070] Step 2: the primary water in step 1 enters the secondary sedimentation tank 200, and after precipitation, its supernatant is taken to obtain secondary water;

[0071] Step 3: The secondary water in step 2 enters the BAF biofilter for treatment, wherein it is treated in the carbon oxidation / nitrification tank 300 for 15 hours, the gas-water ratio is 20:1, and the ammonia nitrogen in the water is under the action of aerobic microorganisms Carry out nitrification reaction, take its supernatant to obtain nitrification water; backwash the nitrification water in a clear water tank, the backwash time is 48h, and the gas backwash intensity: 9L / m 2 .s, water backwash intensity: 4.5L / m 2 .s; then denitrify the backwashed nitrification water in the denitrification tank for 10 hours, the reflux water ratio is 5:1; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com