Acidic heavy metal wastewater treatment method and system

A wastewater treatment system and wastewater treatment technology, applied in water treatment parameter control, water/sewage multi-stage treatment, neutralized water/sewage treatment, etc., can solve the problems of low level of automation control, unstable water quality, waste of resources, etc. problems, to achieve the effect of reducing environmental pollution and waste of resources, reducing chemical consumption and labor costs, and achieving stable water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

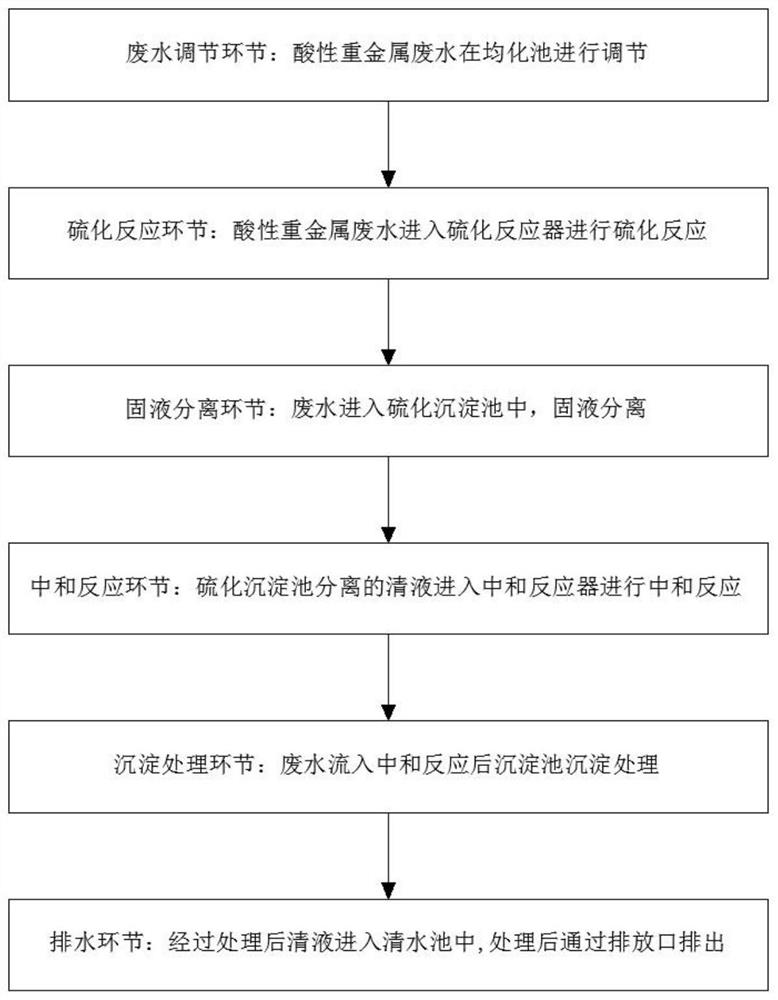

[0037] see figure 1 , a method for treating acidic heavy metal wastewater in the present embodiment, comprising the steps of:

[0038] Step S1, wastewater adjustment link: the acidic heavy metal wastewater is adjusted in the homogenization tank for equalization and homogeneity, and the residence time in the homogenization tank is 3 to 12 hours;

[0039] Step S2, the vulcanization reaction link: the acidic heavy metal wastewater flows into the vulcanization reactor by gravity using the height difference to carry out the vulcanization reaction, and the dosage of the vulcanization agent in the vulcanization reactor is adjusted by controlling the ORP value;

[0040] Step S3, solid-liquid separation link: waste water enters the vulcanization sedimentation tank, PAM flocculant (polyacrylamide) is added to the vulcanization sedimentation tank, and solid-liquid separation is realized by gravity sedimentation, and part of the concentrated mud in the vulcanization sedimentation tank is ...

Embodiment 2

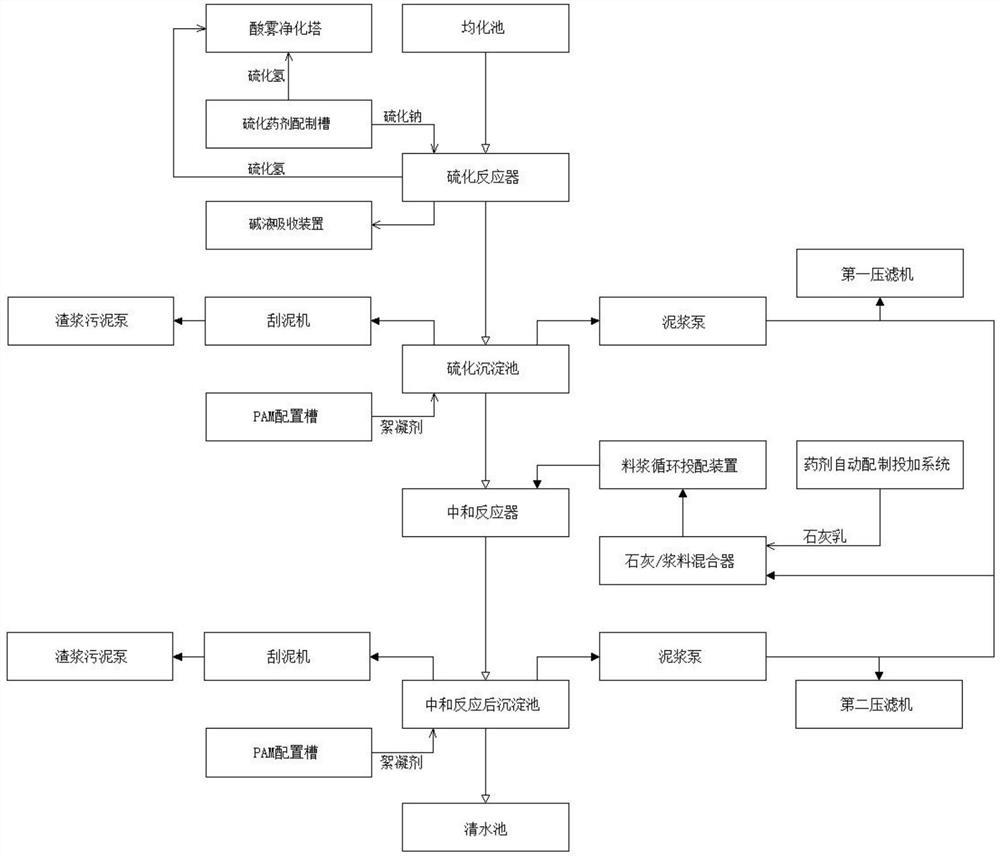

[0051] see figure 2 The present invention provides an acidic heavy metal wastewater treatment system based on the above-mentioned embodiment acidic heavy metal wastewater treatment method, comprising a homogenization tank, a vulcanization reactor, a vulcanization sedimentation tank, a neutralization reactor, a post-neutralization reaction sedimentation tank and The clean water tank, the vulcanization sedimentation tank and the post-neutralization reaction sedimentation tank are all connected to the PAM configuration tank, the neutralization reactor is connected to the lime / slurry mixer, and the lime / slurry mixer is connected to the chemical automatic configuration delivery system, and the sulfuration sedimentation tank After neutralization and reaction, mud pumps are installed in the sedimentation tanks, and the output end of the mud pumps is connected to the lime / slurry mixer through pipelines.

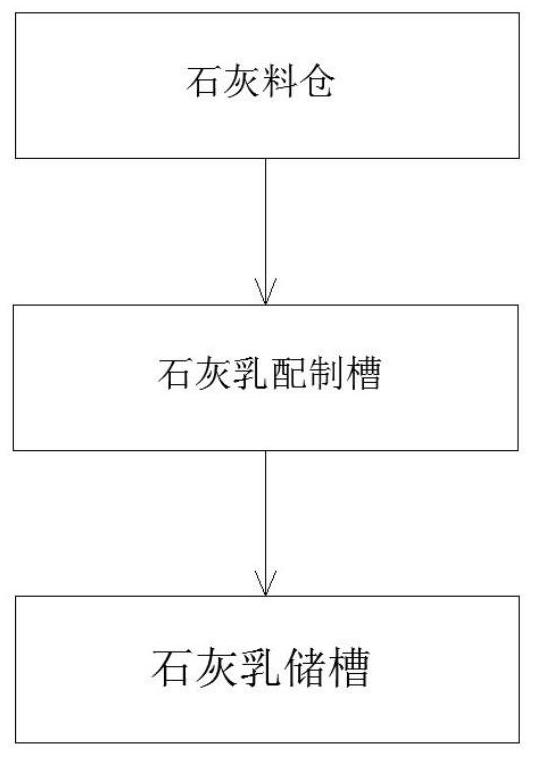

[0052] see image 3 , the automatic preparation and dosing system of the medic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com