3D-printable ultra-high performance concrete as well as preparation method and use method thereof

An ultra-high-performance, 3D printing technology, applied in the field of concrete, can solve the problems of not being able to inherit the high strength and high toughness of UHPC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention also provides a method for preparing the 3D printable ultra-high performance concrete described in the above technical solution, comprising the following steps:

[0057] (1) Portland cement, silica fume, fly ash, quartz powder, fine aggregate, coarse aggregate and stabilizer are mixed to obtain a mixed material;

[0058] Mix the water reducer with water to obtain a mixed slurry;

[0059] mixing cellulose with water to obtain a cellulose solution;

[0060] (2) mixing the mixed material, mixed slurry and cellulose solution obtained in the step (1) to obtain a mixture;

[0061] (3) mixing steel fibers with the mixture obtained in step (2) to obtain 3D printable ultra-high performance concrete.

[0062] The invention mixes Portland cement, silica fume, fly ash, quartz powder, fine aggregate, coarse aggregate and stabilizer to obtain a mixed material. The present invention has no special limitation on the operation of mixing the Portland cement, sili...

Embodiment 1

[0078] In terms of parts by weight, 612 parts of Portland cement with a strength grade of 52.5, 200 parts of silica fume with a particle size of 6 μm to 8 μm, 112 parts of fly ash with a particle size of 350 μm to 380 μm, and a particle size of 0.09 mm to 336 parts of 0.10mm quartz powder, the particle size is 0.22-0.23mm, and the bulk density is 1620kg / m 3 360 parts of quartz sand, the particle size is 1.0-1.11mm, and the bulk density is 1521kg / m 3 504 parts of quartz sand, 68 parts of quick-hardening sulfoaluminate cement and 5 parts of attapulgite are mixed to obtain a mixed material; 10 parts are mixed with 108 parts of water (the mass ratio of water reducer and water is 10:108) to obtain mixed slurry; Parts of water were mixed (the mass ratio of hydroxypropylmethylcellulose to water was 10:108) to obtain a cellulose solution.

[0079] (2) Pre-stir the obtained mixed material in the stirring pot for 120s; then add the obtained mixed slurry into the pre-stirred mixed mat...

Embodiment 2

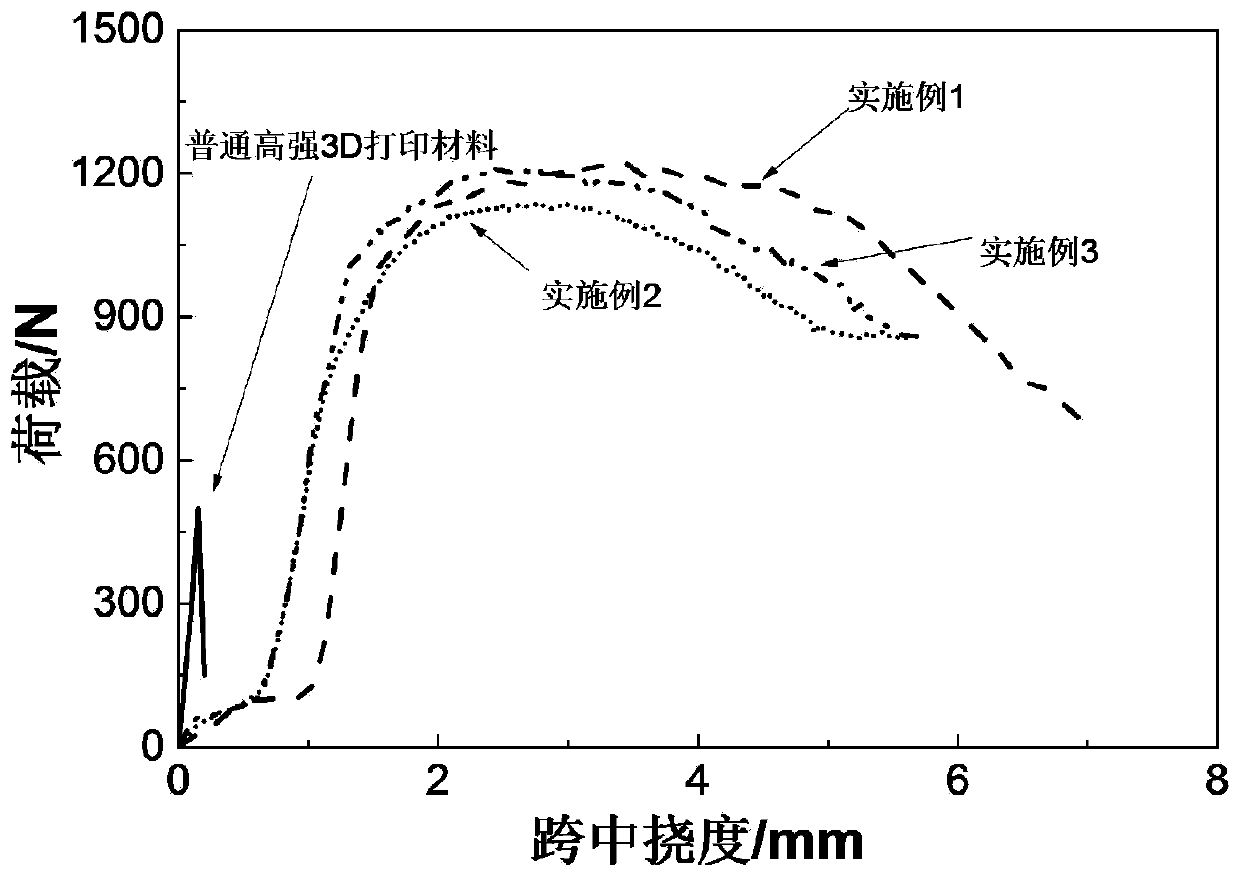

[0082] The difference between Example 2 and Example 1 is that "68 parts of rapid-hardening sulfoaluminate cement and 5 parts of attapulgite" are replaced by "5 parts of attapulgite", and the other steps are the same as in Example 1, that is, the obtained 3D printable ultra-high performance concrete. The 3D printable ultra-high performance concrete is printed using the 3D printing parameters in Example 1, and the obtained products are as follows: image 3 , the mechanical properties are characterized as figure 2 Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com