Liquid crystal polymer film for flexible printed circuit board

A liquid crystal polymer, flexible printing technology, applied in flexible printed circuit boards, printed circuits, printed circuits, etc., can solve the problems of high frequency applications of flexible printed circuit boards, high dielectric constant and dielectric loss factor, and achieve Effects of low dielectric loss factor, low dielectric constant, good dielectric properties and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

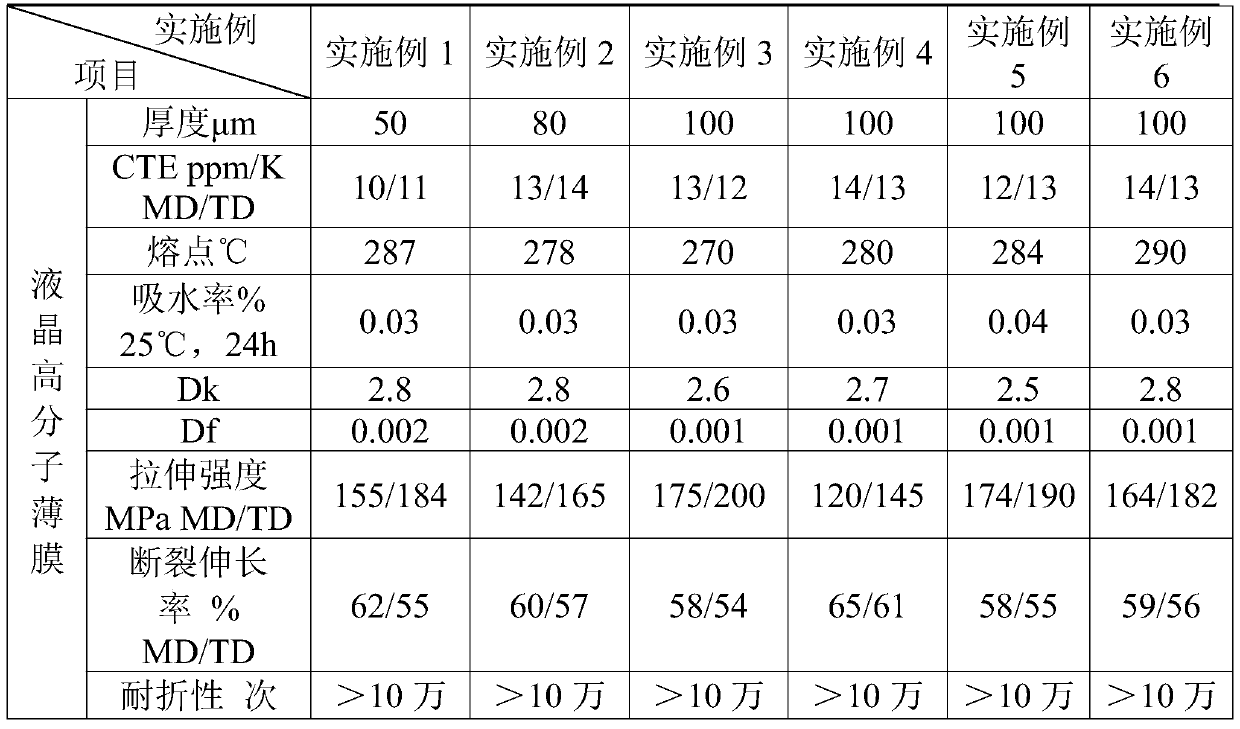

Examples

Embodiment 1

[0066] According to the mass ratio, 75% of A950RX, 21% of DURAFIDE 1130A64, 3% of FG1901 and 1% of Luwax OP are mixed to form a mixture, and the mixture is placed in a twin-screw extruder for melt plasticization, twin-screw extrusion The temperature of the mixture in the discharge machine is 100°C-300°C, the temperature of the die head is 290°C-300°C, the temperature of the cold roll is 240°C, and the melted and plasticized preform is cast into a cast sheet to obtain a prefabricated film.

[0067] The prefabricated film is first stretched longitudinally at a stretching ratio of 2.5 times, and then stretched transversely at a stretching ratio of 3 times at a stretching temperature of 240°C. After stretching, it is wound and cut horizontally to prepare the thickness 50μm liquid crystal polymer film.

[0068] The above-mentioned liquid crystal polymer film is used as the material of the substrate of the flexible printed circuit board to prepare a flexible printed circuit board. ...

Embodiment 2

[0070] In terms of mass ratio, 80% of A950RX, 17.5% of DURAFIDE 1130A64, 2% of FG1901 and 0.5% of Luwax OP are mixed to form a mixture, and the mixture is placed in a twin-screw extruder for melt plasticization, twin-screw extrusion The temperature of the mixture in the discharge machine is 100°C-300°C, the temperature of the die head is 290°C-300°C, the temperature of the cold roll is 220°C, and the melted and plasticized preform is cast into a precast film to obtain a prefabricated film.

[0071] The prefabricated film is first stretched longitudinally, with a stretching ratio of 2 times, and then stretched transversely, with a stretching ratio of 2.5 times, and the stretching temperature is 250°C. After stretching, it is wound and cut horizontally to prepare the thickness 80μm liquid crystal polymer film.

[0072] The above-mentioned liquid crystal polymer film is used as the material of the substrate of the flexible printed circuit board to prepare a flexible printed circu...

Embodiment 3

[0074] According to the mass ratio, 85% of A950RX, 12.5% of DURAFIDE 1130A64, 2% of FG1901 and 0.5% of Luwax OP are mixed to form a mixture, and the mixture is placed in a twin-screw extruder for melt plasticization, twin-screw extrusion The temperature of the mixture in the discharge machine is 100°C-300°C, the temperature of the die head is 290°C-300°C, the temperature of the cold roll is 220°C, and the melted and plasticized preform is cast into a precast film to obtain a prefabricated film.

[0075] The prefabricated film is first stretched longitudinally, with a stretching ratio of 3 times, and then stretched transversely, with a stretching ratio of 3 times, and the stretching temperature is 260°C. After stretching, it is wound and cut horizontally to prepare the thickness 100μm liquid crystal polymer film.

[0076] The above-mentioned liquid crystal polymer film is used as the material of the substrate of the flexible printed circuit board to prepare a flexible printed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com