Novel antibacterial and antiviral multifunctional coating and preparation method thereof

An anti-viral and multi-functional technology, applied in the field of coatings, can solve the problems of less research on anti-viral coatings, research and production technology of anti-bacterial and anti-viral coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

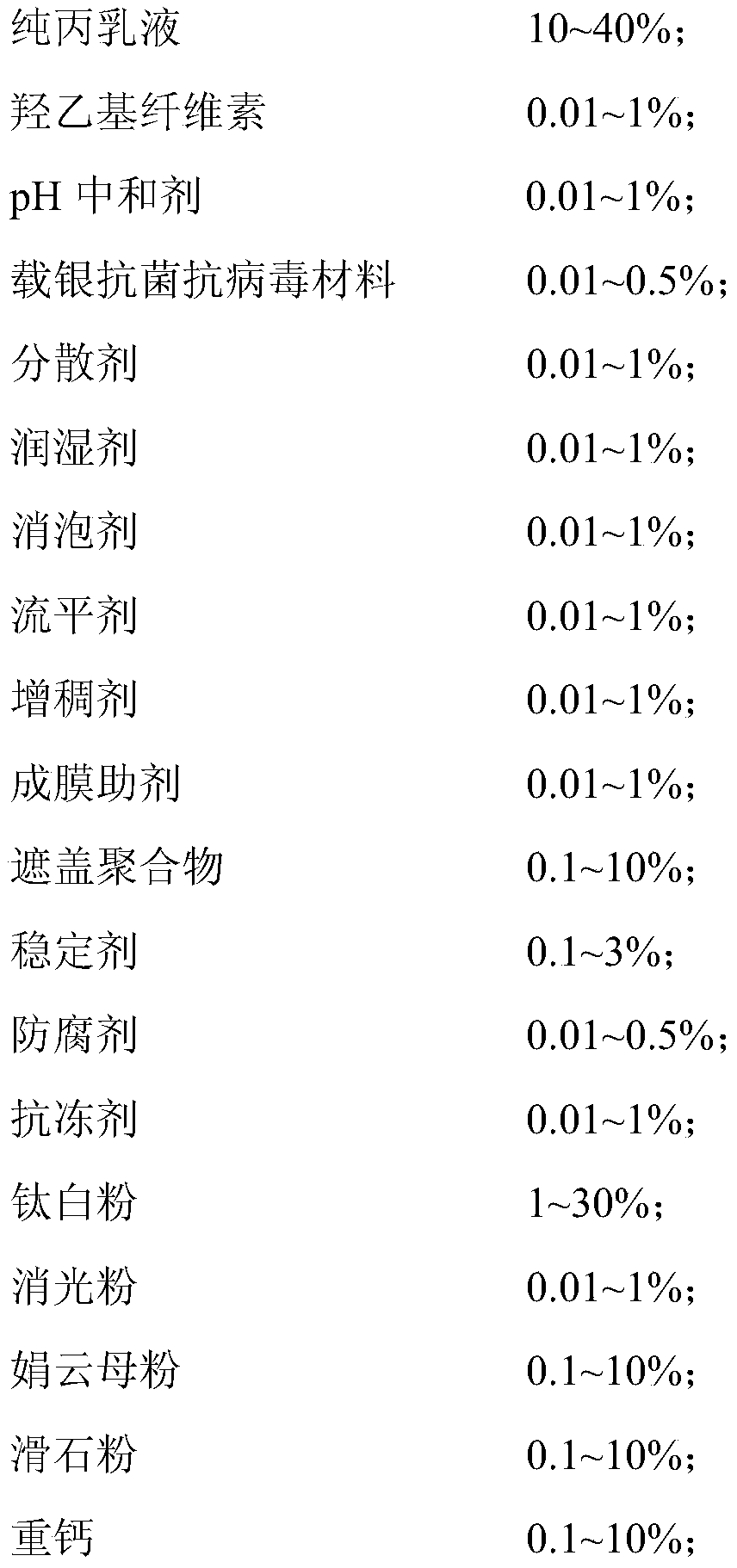

Image

Examples

Embodiment 1

[0055] (1) Preparation of antibacterial and antiviral materials

[0056] 1 ~ 30μm Ag 2 SiO 3 Powder and Ag@Zr(HPO 4 ) 2 The powders were uniformly mixed according to the proportions stated in Table 1 to prepare silver-loaded antibacterial and antiviral materials.

[0057] (2) Preparation of stabilizer

[0058] Mix tetramethylsilane, vinyltrimethoxysilane and propylene glycol uniformly at a weight ratio of 1:2:2, and irradiate with ultraviolet light at 25°C for 10 minutes to prepare a stabilizer.

[0059] (3) Preparation of new antibacterial and antiviral multifunctional coatings

[0060] S10. Weigh each component according to the component dosage shown in Table 1 for later use.

[0061] S20, dissolving the hydroxyethyl cellulose in the water, then adding the pH neutralizer and stirring at 1000r / min for 20min to prepare a first mixture;

[0062] S30. Disperse the dispersant, the wetting agent and the defoamer in the first mixture at 500r / min, stir for 3min, and then add ...

Embodiment 2

[0067] (1) Preparation of antibacterial and antiviral materials

[0068] 1 ~ 30μm Ag 2 SiO 3 Powder and Ag@Zr(HPO 4 ) 2 The powders were uniformly mixed according to the proportions stated in Table 1 to prepare silver-loaded antibacterial and antiviral materials.

[0069] (2) Preparation of stabilizer

[0070] The tetramethylsilane, the vinyltrimethoxysilane and the propylene glycol were uniformly mixed in a weight ratio of 2:1:3, and irradiated with ultraviolet light at 20° C. for 20 minutes to prepare a stabilizer.

[0071] (3) Preparation of new antibacterial and antiviral multifunctional coatings

[0072] S10. Weigh each component according to the component dosage shown in Table 1 for later use.

[0073] S20, dissolving the hydroxyethyl cellulose in the water, then adding the pH neutralizer and stirring at 1000r / min for 15min to prepare a first mixture;

[0074] S30. Disperse the dispersant, the wetting agent and the defoamer in the first mixture at 500r / min, stir f...

Embodiment 3

[0079] (1) Preparation of antibacterial and antiviral materials

[0080] 1 ~ 30μm Ag 2 SiO 3 Powder and Ag@Zr(HPO 4 ) 2 The powders were uniformly mixed according to the proportions stated in Table 1 to prepare silver-loaded antibacterial and antiviral materials.

[0081] (2) Preparation of stabilizer

[0082] The tetramethylsilane, the vinyltrimethoxysilane and the propylene glycol were uniformly mixed in a weight ratio of 3:0.5:5, and irradiated with ultraviolet light at 10° C. for 30 minutes to prepare a stabilizer.

[0083] (3) Preparation of new antibacterial and antiviral multifunctional coatings

[0084] S10. Weigh each component according to the component dosage shown in Table 1 for later use.

[0085] S20, dissolving the hydroxyethyl cellulose in the water, then adding the pH neutralizer and stirring at 1000r / min for 25min to prepare a first mixture;

[0086] S30. Disperse the dispersant, the wetting agent and the defoamer in the first mixture at 500r / min, stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com