Wave-absorbing material with three-layer hollow structure as well as preparation method and application thereof

A technology of wave absorbing material and hollow structure, applied in the field of wave absorbing material, can solve the problem of strong wave absorbing performance, and achieve the effect of wide wave absorbing frequency band, light weight and large hollow volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention provides a preparation method of three-layer hollow nanoparticles. The material is applied in the fields of wave absorption, energy and catalysis. The preparation method includes the following steps:

[0037] (1) reducing the ferrous sulfate reaction solution to obtain iron particles;

[0038] (2) plating a layer of metal on the surface of the iron particles to obtain the iron particles covered by the metal;

[0039] (3) using dilute hydrochloric acid to corrode the iron particles covered by the metal to obtain hollow metal nanoparticles;

[0040] (4) Coating a layer of metal on the hollow metal nanoparticles to obtain two layers of metal hollow nanoparticles.

[0041] (5) The two-layer metal hollow nanoparticles are hydrothermally reacted to obtain three-layer hollow nanoparticles

[0042] The three-layer hollow nanoparticles provided by the present invention are respectively a magnetic metal layer, an intermetallic compound layer, and a metal o...

Embodiment

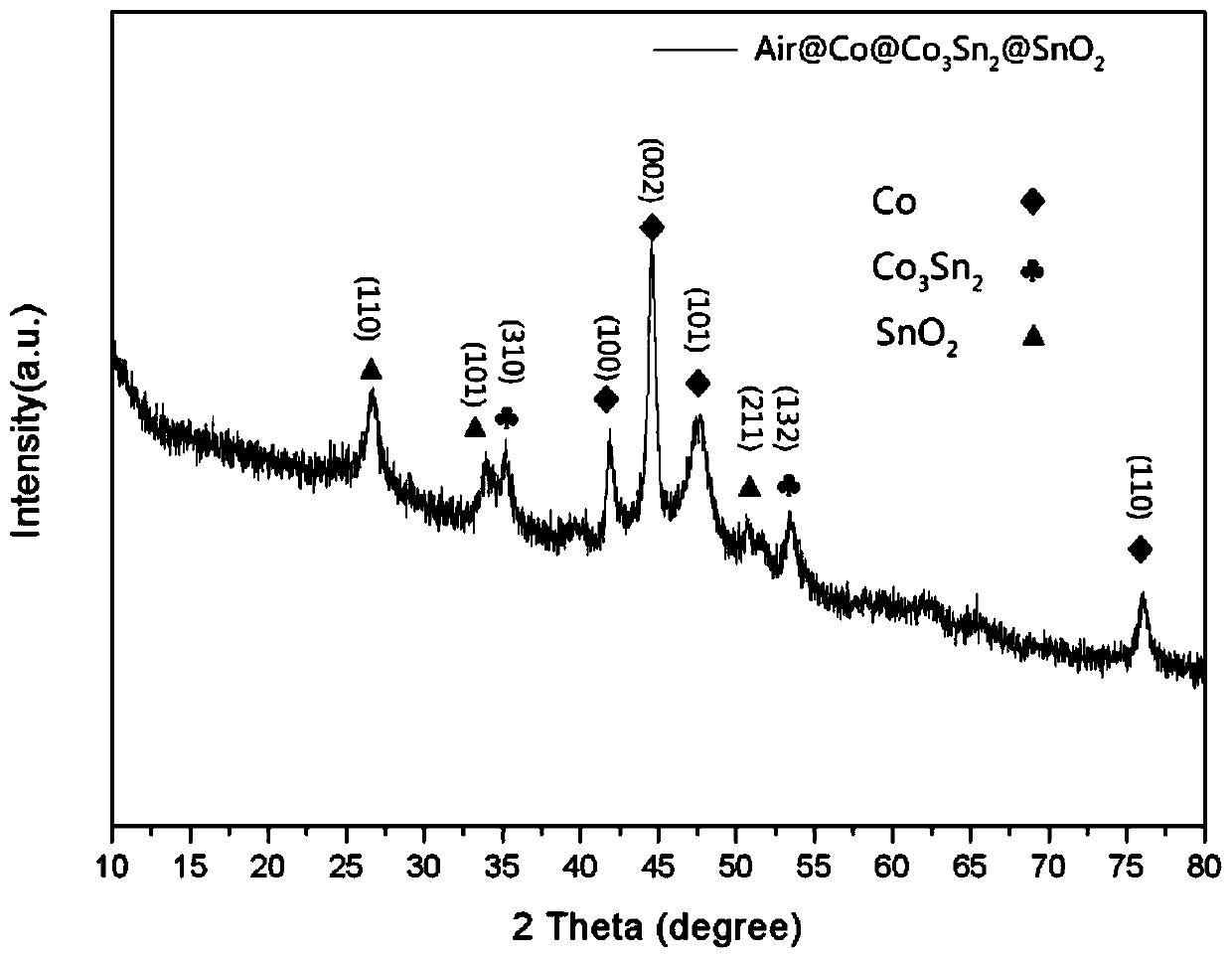

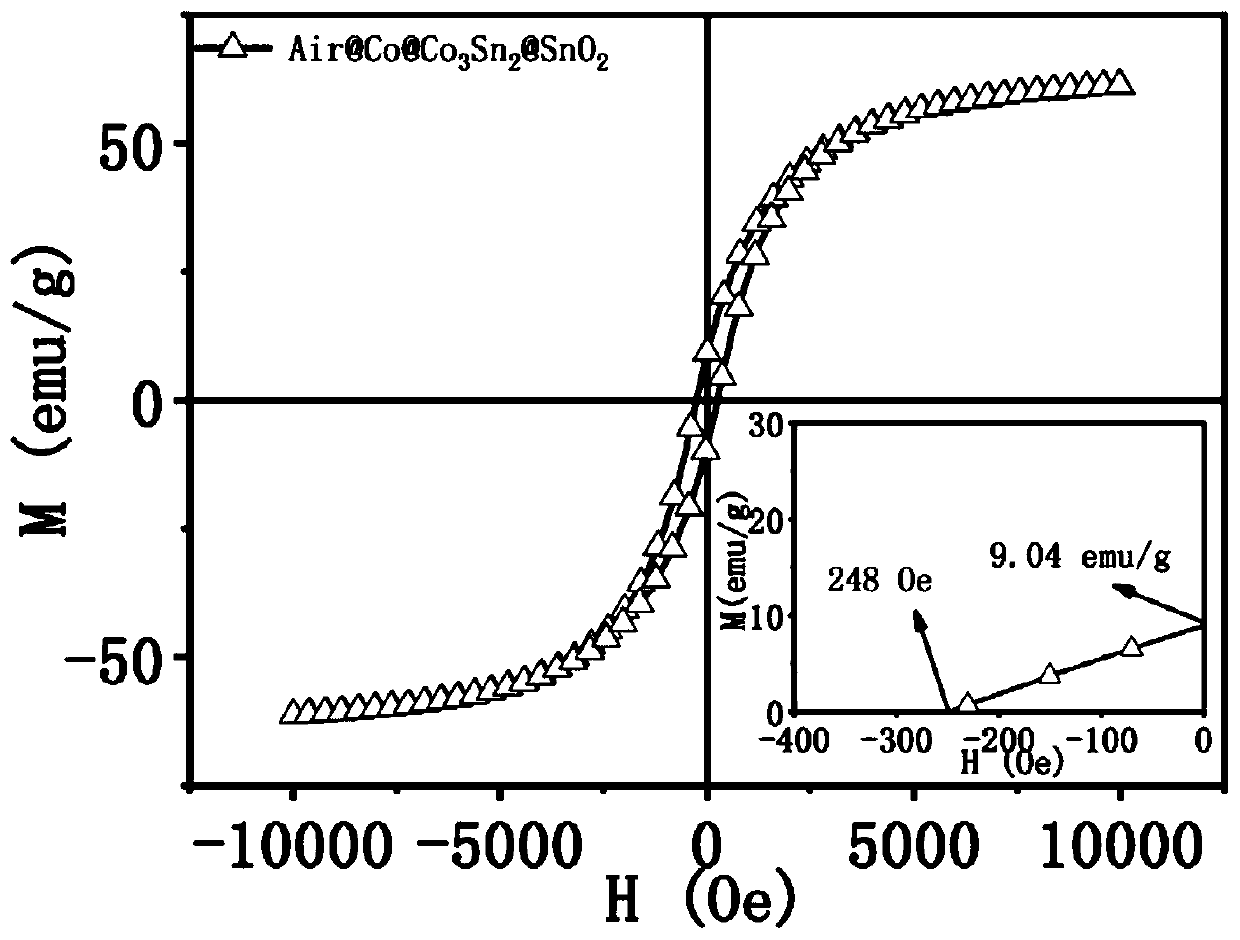

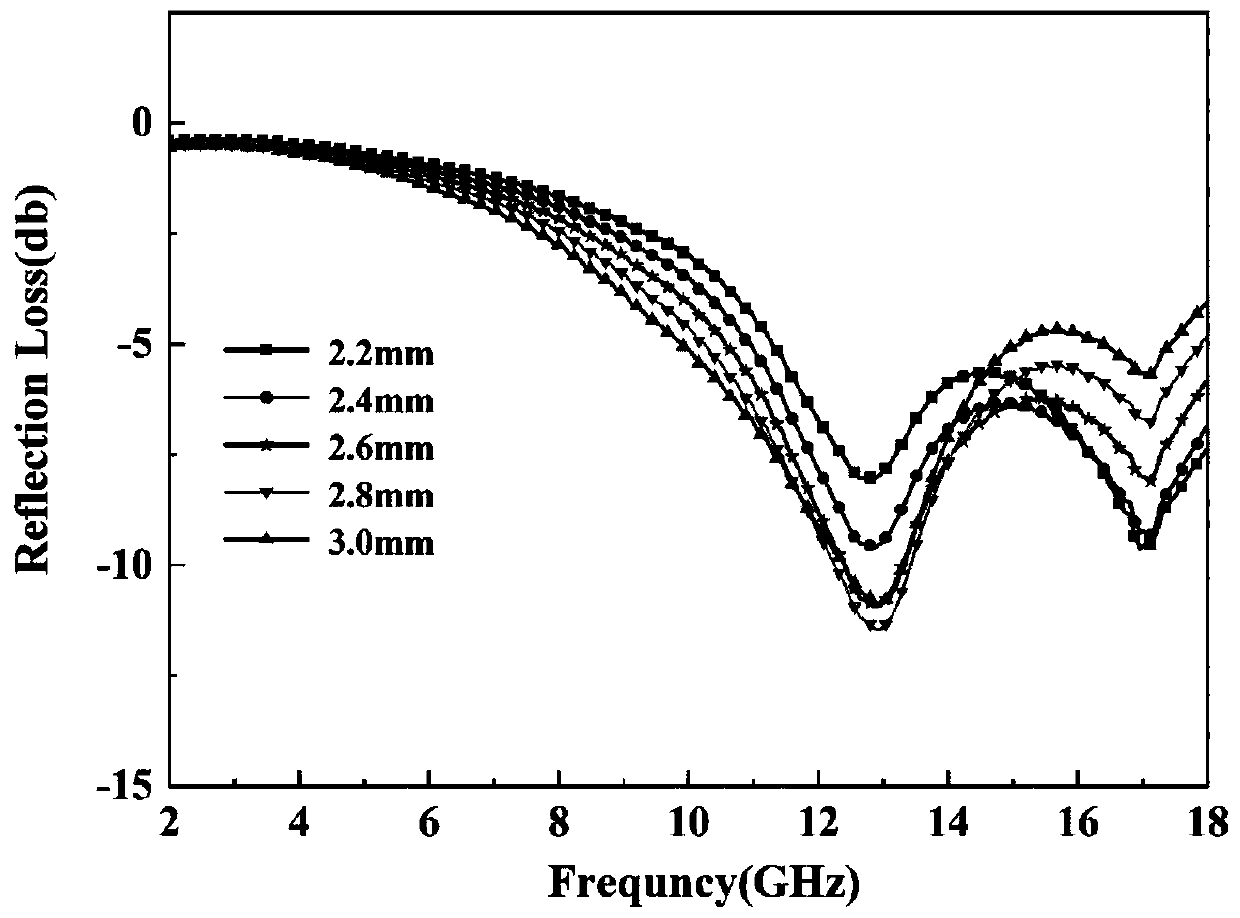

[0072] Air@Co@Co 3 sn 2 @SnO 2 Three layers of hollow nanoparticles:

[0073] aUsing NaBH 4 Reduced FeSO 4 , to get Fe particles.

[0074] Preparation of reaction solution and reducing solution

[0075] Reaction solution: FeSO 4 ·7H 2 O, 0.1mol / L×100ml, used after preparation Medium-speed qualitative filter paper filtration.

[0076] Reducing solution: NaBH 4 , 0.5mol / L×40ml+60ml NH 3 ·H 2 O, the two are fully mixed before use.

[0077] Use a constant current pump to drop the mixed reducing solution into the reaction solution and keep stirring, the titration rate is 3ml / min; the water bath is heated at a temperature of 40°C; Fe particles with a particle size of 280-330nm are generated.

[0078] The Fe particles were ultrasonically cleaned three times with deionized water, each time for one minute, to obtain Fe particles.

[0079] b electroless cobalt plating:

[0080] Reaction solution: CoSO 4 ·7H 2 O 0.027mol / L, KNaC 4 O6H 4 0.021mol / L, a total of 300ml o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com