Double-row automatic ditching machine for saline-alkali soil improvement and construction method thereof

A trencher and saline-alkali land technology are applied in the field of double-row automatic trencher and its construction, which can solve the problems of low construction efficiency, long construction time, and increase the labor intensity of workers, so as to shorten the construction efficiency and construction time. The effect of short time and low labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

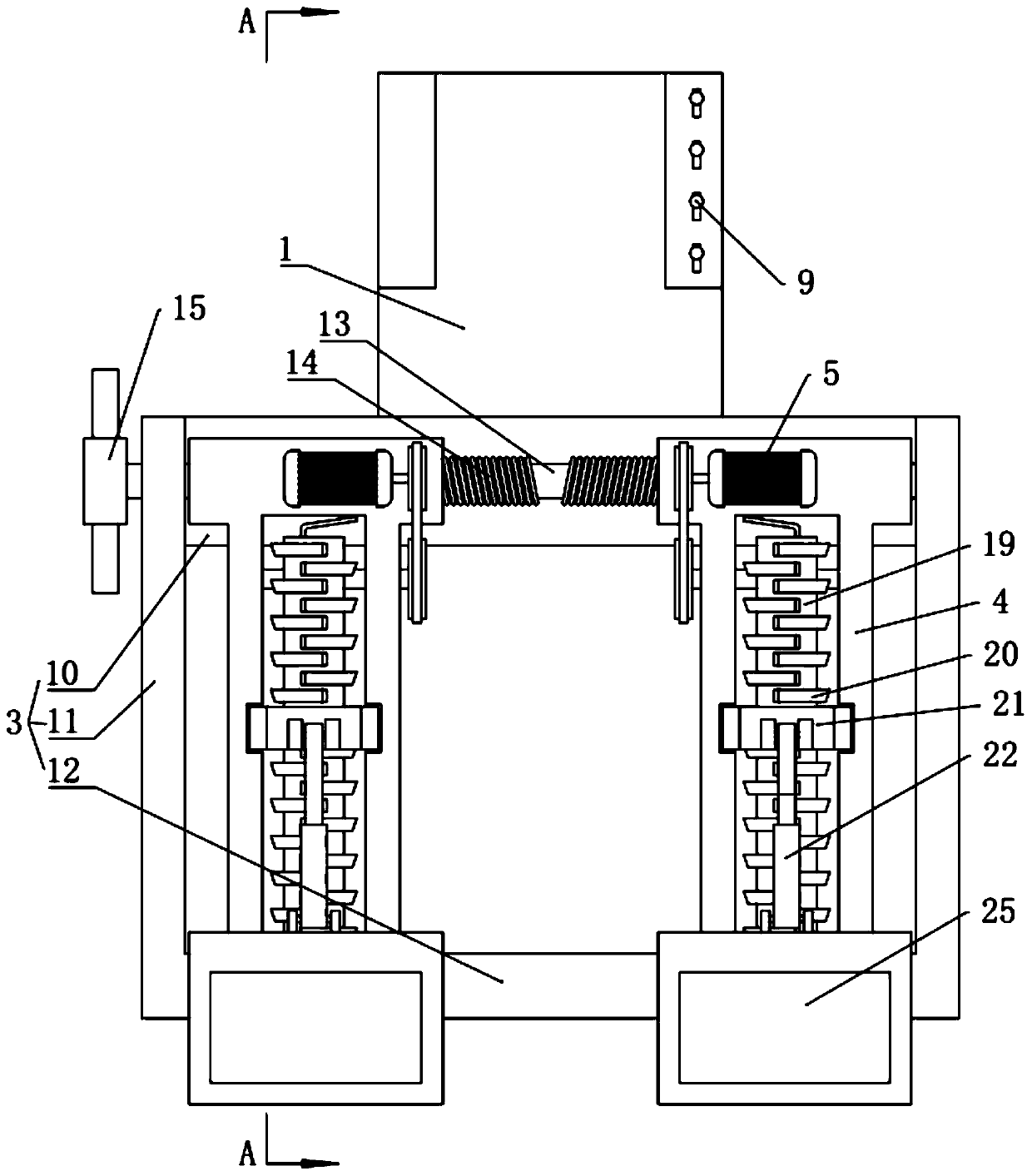

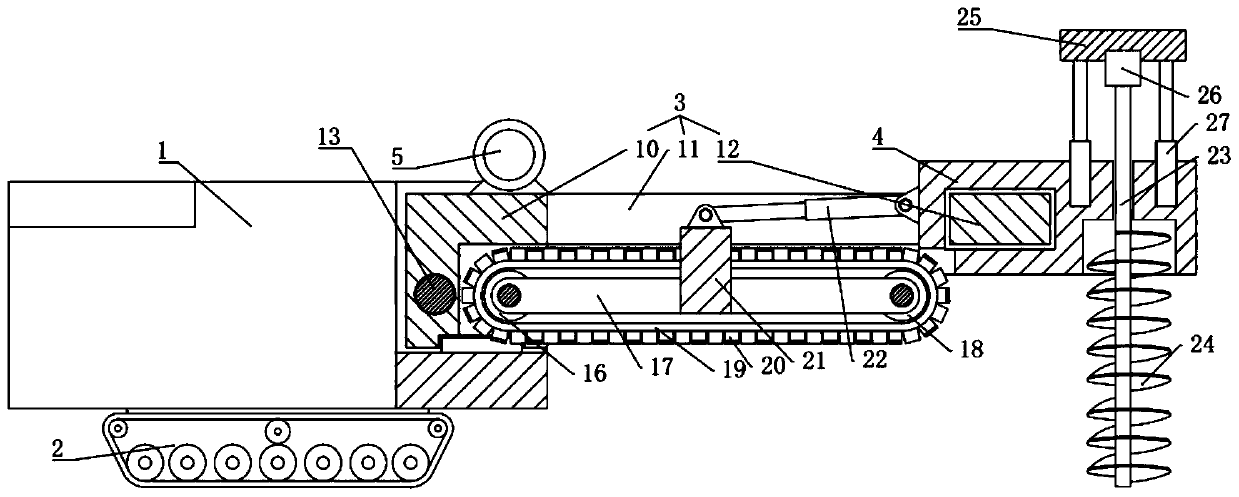

[0036] like Figure 1-Figure 3 Commonly shown, the double-row automatic ditching machine for saline-alkali land improvement includes a body 1, and the two sides of the bottom of the body 1 are symmetrically arranged on the track wheels 2 for driving the body 1 forward. The body 1 is provided with a ditching device and Control system for controlling trenching devices.

[0037] The ditching device includes a fixed frame 3 fixed to the rear end of the body 1, on which two symmetrically arranged mounts 4 are slidably installed, and a slide is provided between the ends of the two mounts 4 near the body 1 and the fixed frame 3. mechanism, each mounting seat 4 is provided with a ditching mechanism driven by the first drive motor 5, and each mounting seat 4 is provided with a drilling mechanism at one end away from the body 1.

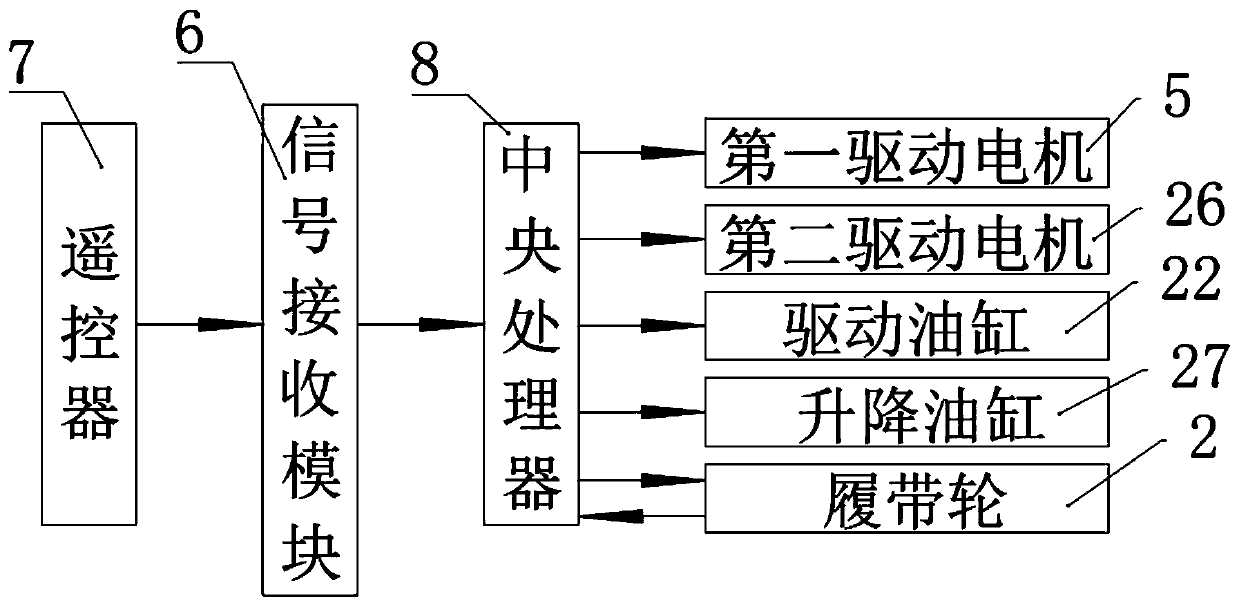

[0038] The control system includes a central processing unit 8 that is communicatively connected with the signal receiving module 6 and the remote controller...

Embodiment 2

[0052] The construction method of the double-row automatic ditching machine for the improvement of saline-alkali land includes the following steps:

[0053] S1. Adjust the ditching distance, turn the rotary handle 15 as required, and adjust the distance between the two mounting seats 4 by adjusting the screw 13, so as to adjust the distance between the two ditching mechanisms to a suitable size;

[0054] S2. Adjust the depth of ditching. After the remote controller 7 controls the ditching machine to move to the position where ditching needs to be done, control the first drive motor 5 to start and drive the ditching mechanism to start running, and then use the remote controller according to the required ditching depth. 7. The piston rod of the driving oil cylinder 22 is controlled to stretch out, and drives the rear end of the ditching mechanism to rotate downwards to adjust the ditching depth of the ditching mechanism;

[0055] S3, fixed-distance drilling, the remote control 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com