Stratum adaptation evaluation method for pushing type rotary steering system

A technology of rotary steering and evaluation method, which is applied in the field of oil drilling, and can solve problems such as evaluation of stratum adaptability of the pushable rotary steerable system, and achieve the effect of avoiding control failure and improving effectiveness and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

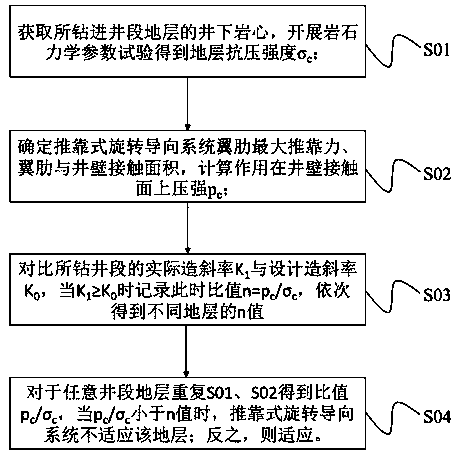

[0023] As a preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0024] A method for evaluating formation adaptation of a push-by rotary steerable system, characterized in that it includes the following steps:

[0025] A. Steps for obtaining the compressive strength of the formation: collect the downhole cores of the strata in the drilled well section, and perform a compressive strength compression test on the collected downhole cores to obtain the compressive strength σ of the formation c ;

[0026] B. Acquisition of the pressure of the rib acting on the well wall contact surface: According to the maximum thrust force P of the wing rib and the contact area A between the wing rib and the well wall of the pushing rotary steerable system, the action of the wing rib on the well wall contact surface is obtained pressure p c ;

[0027] C. Adaptability evaluation step: compare the actual build-up rate K of the drilled...

Embodiment 2

[0029] As another preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0030] A formation adaptation evaluation method of a push-by rotary steerable system, comprising the following steps:

[0031] A. Steps for obtaining the compressive strength of the formation: collect the downhole cores of the strata in the drilled well section, and perform a compressive strength compression test on the collected downhole cores to obtain the compressive strength σ of the formation c ; collect the downhole core of the drilled well section formation, process the downhole core into a cylindrical test sample with a diameter of 25 mm and a length of 50 mm, and grind the two ends of the test sample. The average value of the compressive strength of all test samples is taken as the compressive strength σ of the formation c ;

[0032] B. Acquisition of the pressure of the rib acting on the well wall contact surface: According to the ma...

Embodiment 3

[0035] As another preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0036] A formation adaptation evaluation method of a push-by rotary steerable system, comprising the following steps:

[0037] A. Steps for obtaining the compressive strength of the formation: collect the downhole cores of the strata in the drilled well section, and perform a compressive strength compression test on the collected downhole cores to obtain the compressive strength σ of the formation c ; collect the downhole core of the drilled well section formation, process the downhole core into a cylindrical test sample with a diameter of 25 mm and a length of 50 mm, and grind the two ends of the test sample. The average value of the compressive strength of all test samples is taken as the compressive strength σ of the formation c .

[0038] B. Acquisition of the pressure of the rib acting on the well wall contact surface: According to the maxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com