Nitrogen sealing system and method for turbo expander with function of bearing box cooling

A turboexpander, nitrogen sealing technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problem of difficult to take into account the cooling of gas turbine sealed bearing boxes, etc. Service life, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

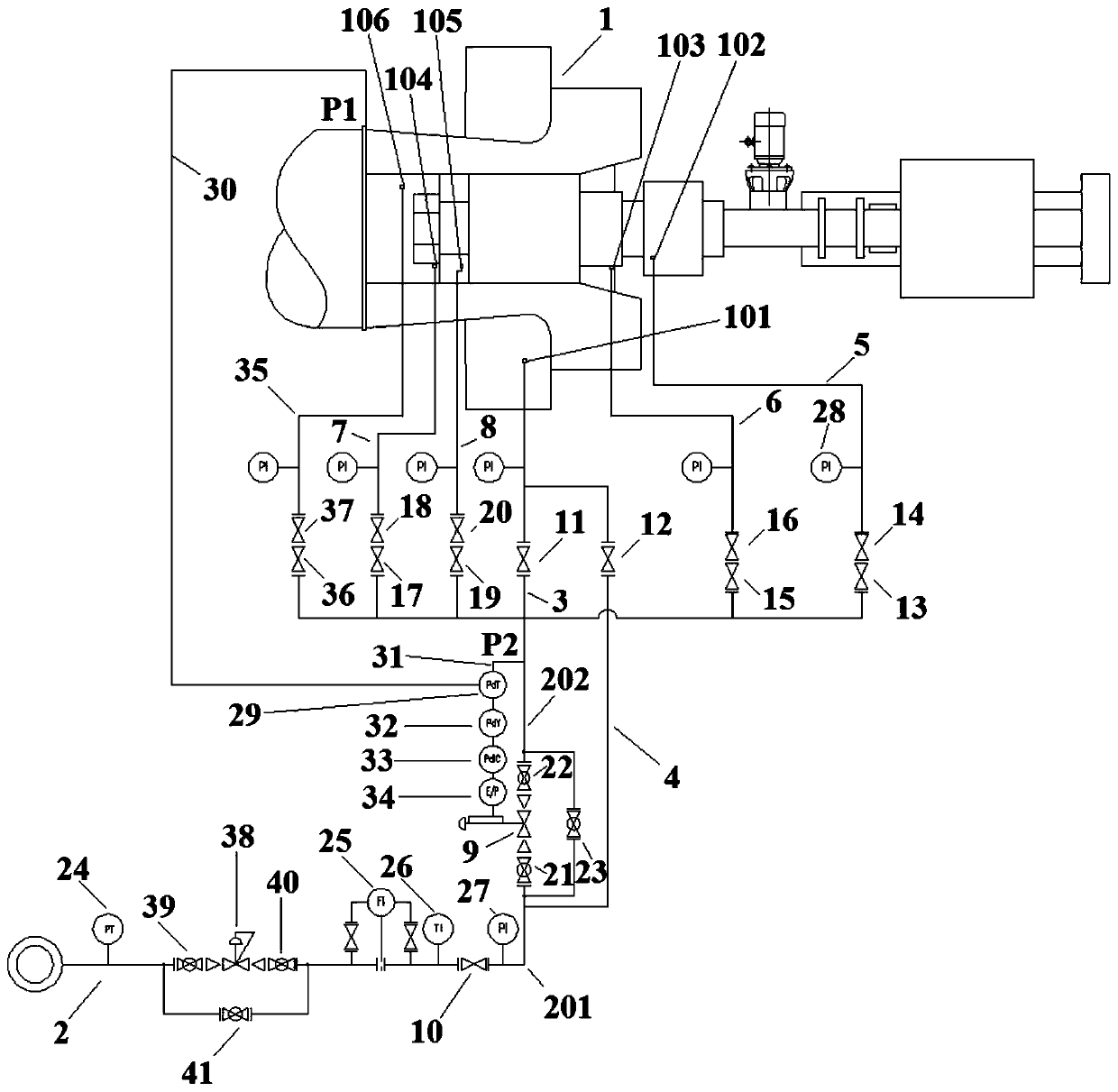

[0042] This embodiment provides a nitrogen sealing system for a turboexpander with cooling of the bearing box, such as figure 1 As shown, it includes a turboexpander 1, and the turboexpander 1 is provided with a nitrogen filling port 101 for the vane adjustment chamber, a carbon ring seal nitrogen filling port 102 on the intake side, a labyrinth seal nitrogen filling port 103 on the intake side, and an exhaust Side carbon ring seal nitrogen filling port 104, exhaust side labyrinth seal nitrogen filling port 105 and exhaust side bearing box nitrogen filling port 106;

[0043] It also includes the main pipeline 2, the sealing pipeline of the stator blade adjustment chamber A 3, the sealing pipeline of the stator blade adjustment chamber B 4, the carbon ring sealing pipeline on the intake side 5, the labyrinth sealing pipeline on the intake side 6, the carbon ring on the exhaust side Sealing pipeline 7, exhaust side labyrinth sealing pipeline 8 and exhaust side bearing box coolin...

Embodiment 2

[0053] This embodiment provides a nitrogen sealing method for a turboexpander with cooling of the bearing box, which uses the nitrogen sealing system for the turboexpander with cooling of the bearing box in Example 1 to seal the turboexpander 1 The static vane adjustment cavity, the carbon ring seal on the intake side, the labyrinth seal on the intake side, the carbon ring seal on the exhaust side and the labyrinth seal on the exhaust side are filled with nitrogen to seal the bearing housing on the exhaust side of turbo expander 1. Nitrogen cooling.

[0054] Specifically, in this method, the pressure behind the regulating valve is 0.4-0.6MPa; the pressure behind the regulating valve is kept 20-30kPa higher than the pressure of the sealed gas, and the pneumatic pressure is adjusted according to the real-time detection value of the pressure behind the regulating valve and the pressure of the sealed gas. The membrane regulating valve 9 performs real-time adjustment, and the nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com