Combined electric appliance partial discharge vibration detection method

A partial discharge and vibration detection technology, applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve the problems of equipment failure, threat to the safety of operators, and emerge in an endless stream, and achieve the effect of high accuracy, convenient use and convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

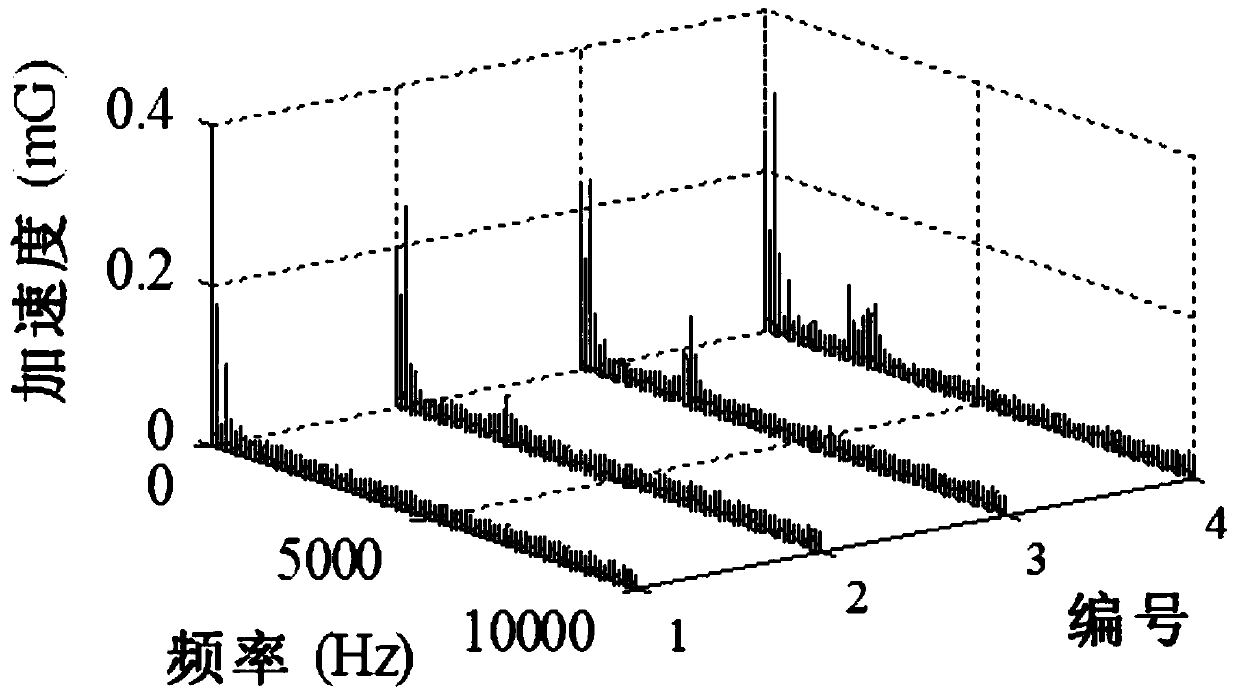

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

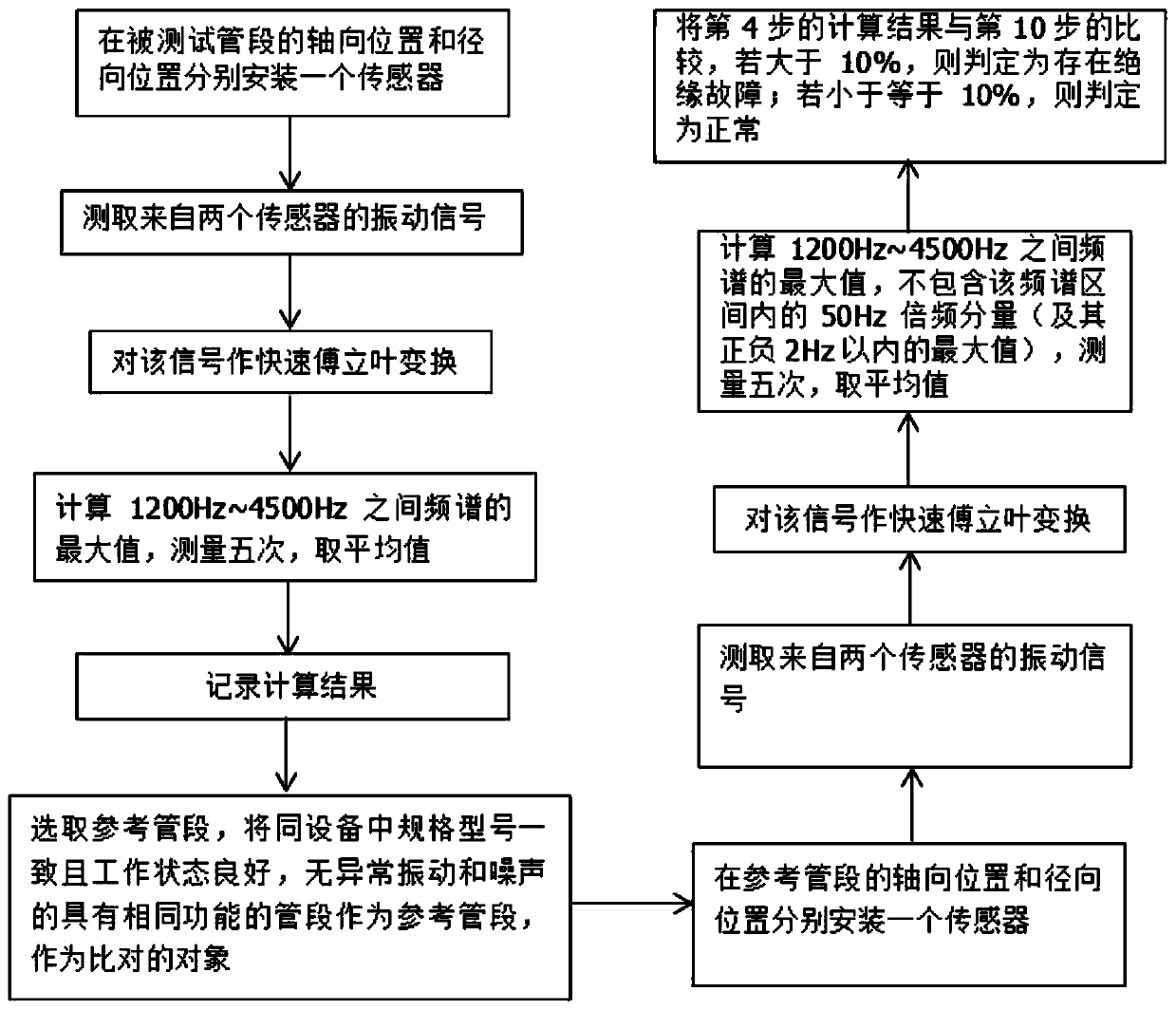

[0032] A method for detecting vibration of partial discharge of combined electrical appliances, such as figure 1 shown, including the following steps:

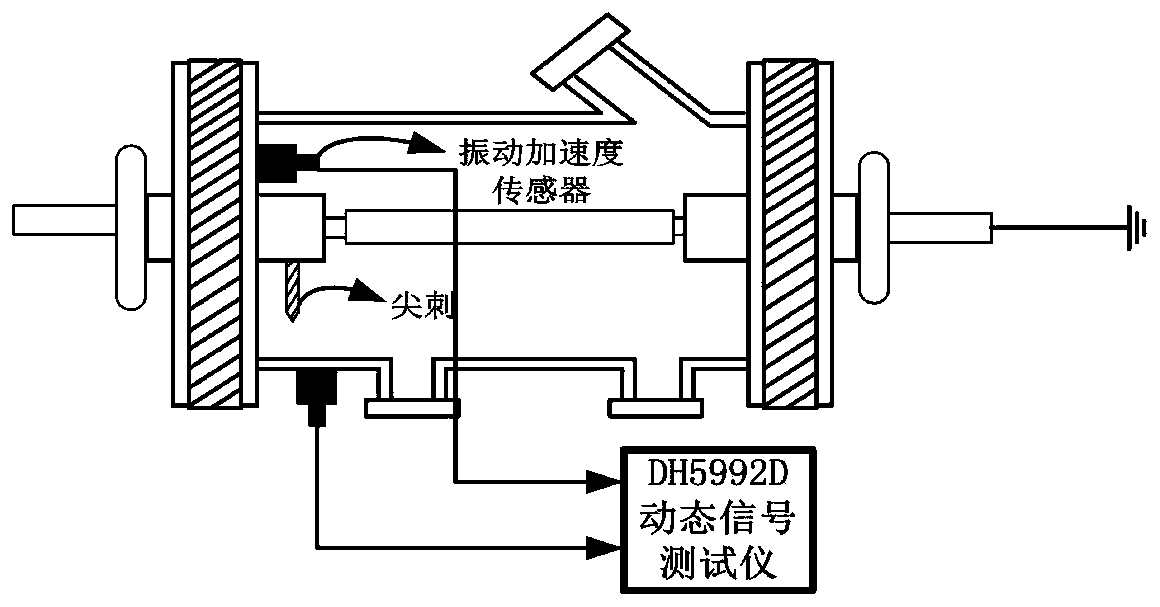

[0033] Step 1. Select a detection position on the pipe section to be tested, and install a vibration acceleration sensor on its axial and radial positions respectively.

[0034] In this step, the placement of the acceleration vibration sensor is based on the principle that the detected vibration signal is the strongest. After testing, the vibration signal detected at the flanges at both ends of the gas chamber is weak, and the vibration signal detected at the middle of the gas chamber is strong. Therefore, the vibration sensor is placed in the middle of a section of air chamber for detection. In addition, considering the difference between the vibration propagation direction and the vibration characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com