A kind of injection molded frame circular electrode connector and its manufacturing method

A technology of circular electrodes and connectors, applied in the direction of connection, connection, clamping/spring connection and other directions where permanent deformation plays a role, it can solve the problems of poor wear resistance and insufficient strength of electrical connector structural parts, and achieve high durability Wear characteristics, high structural strength, cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

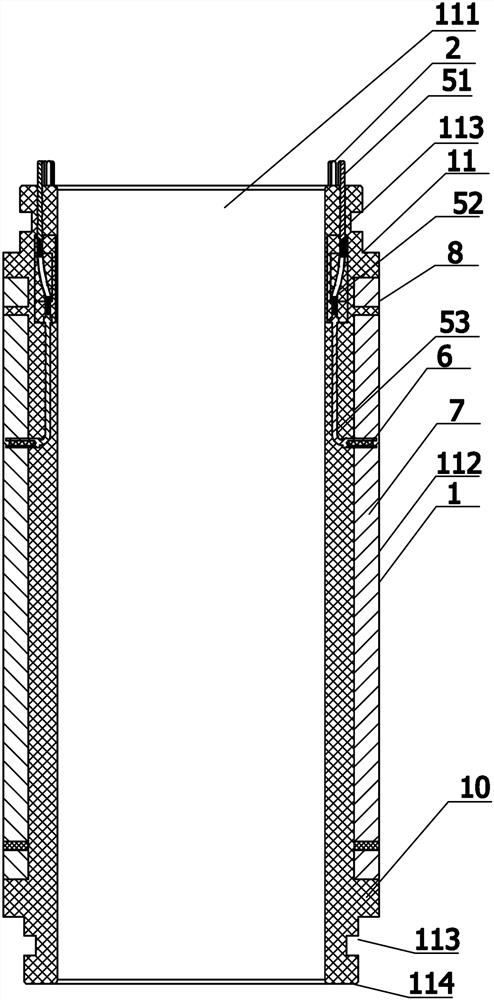

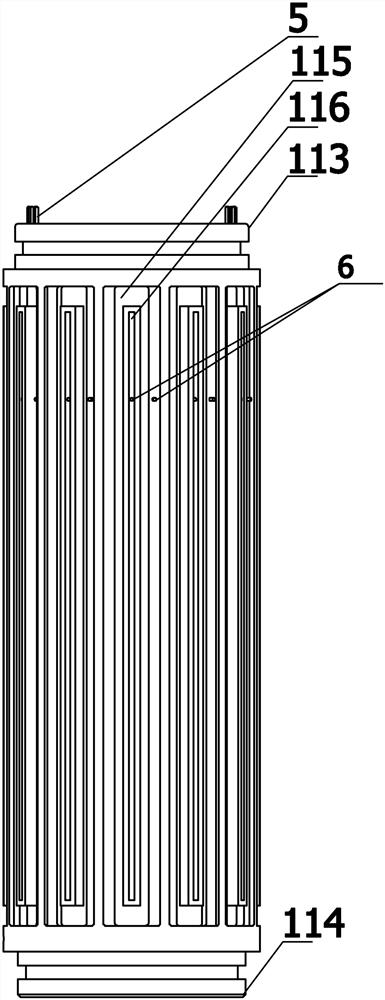

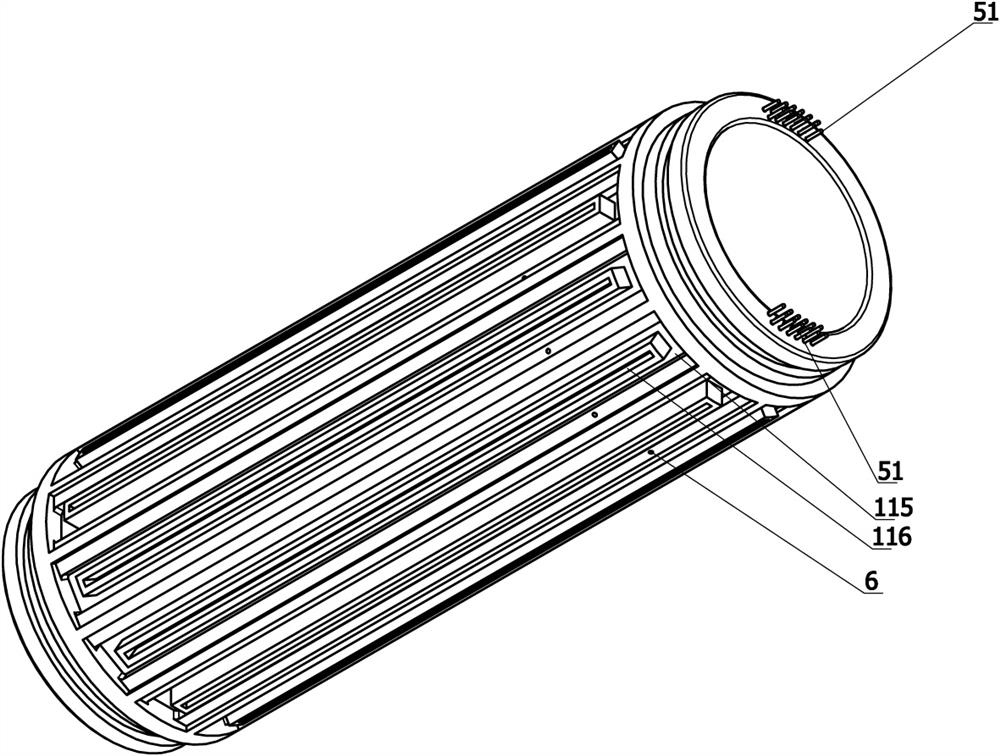

[0049] Such as Figure 1~Figure 19 As shown, a circular electrode connector with an injection molded skeleton, the electrode connector 1 includes an outer shell fitting 11, an inner fitting 2 partially embedded in the outer shell fitting 11, and a plurality of inner fittings arranged outside the outer shell fitting 11. The inner fitting 2 is electrically connected to a plurality of contacts. The inner fitting 2 is embedded in the outer casing fitting 11, and a plurality of contact pieces are respectively arranged on the outer circumferential curved surface of the outer casing fitting 11. A part of the inner fitting 2 extends out of the outer casing fitting 11, and the inner fitting 2 A part embedded in the housing assembly 11 is electrically connected to the contact. And a metal elastic piece 6 is provided between the electrical connection of the inner fitting piece 2 and the contact piece.

[0050] Such as Figure 7~Figure 15 As shown, the inner fitting 2 includes a fixed ...

Embodiment 2

[0062] On the basis of the first embodiment, the crimping member 5 connects the straight pin 51 and the bent pin 53 through the high temperature wire 52 . The second electrode block 8 and the first electrode block 7 are respectively connected to the straight pins 51 of the crimping member 5 . The straight pins 51 and the bent pins 53 are overlapped by the high-temperature wires 52 , and different connection arrangements are realized through the high-temperature wires 52 , thereby realizing sampling outputs of different arrangements. Among the two rows of straight pins 51 arranged inside and outside the inner fitting 2, the inner row of straight pins 51 is electrically connected to the second electrode block 8; the outer row of straight pins 51 is electrically connected to the first electrode block 7.

Embodiment 3

[0064] A method for manufacturing an injection-molded skeleton circular electrode connector, comprising the following steps:

[0065] Step 1, positioning and supporting several crimping parts 5 through the fixing ring 3, combining the crimping parts 5 with the transfer support ring 4 to form the inner fitting part 2; screwing the screw 303 into the threaded hole provided on the fixing ring 3 302 , limit the combination of the pressing joint 5 and the fixing ring 3 . Specifically, one end of the crimping member 5 is provided with a recessed receiving hole 537, and a blocking block 533 for blocking the receiving hole 537 is also provided on the receiving hole 537; the blocking block 533 of the crimping member 5 is correspondingly embedded into the retaining ring 3.

[0066] The assembly steps of the crimping joint 5 include: lapping the straight pin 51 with the bent pin 53 through the high-temperature wire 52, and coating the outside of the joint where the straight pin 51, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com