Automatic processing equipment for substrate of circuit board

A technology for processing equipment and circuit boards, which is applied in the field of automatic processing equipment for circuit board substrates, can solve problems such as low processing efficiency, high rate of missed detection by manual detection, and failure of manual detection to achieve processing, so as to improve processing efficiency and ensure processing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

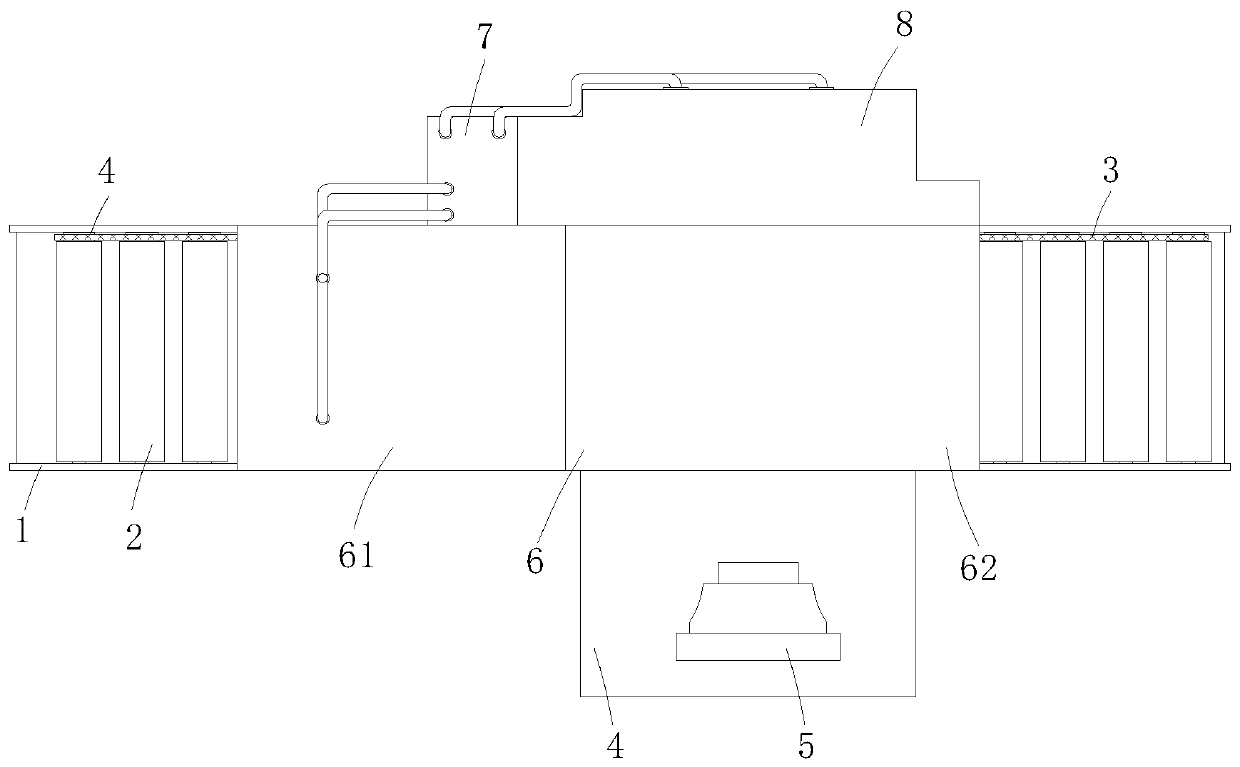

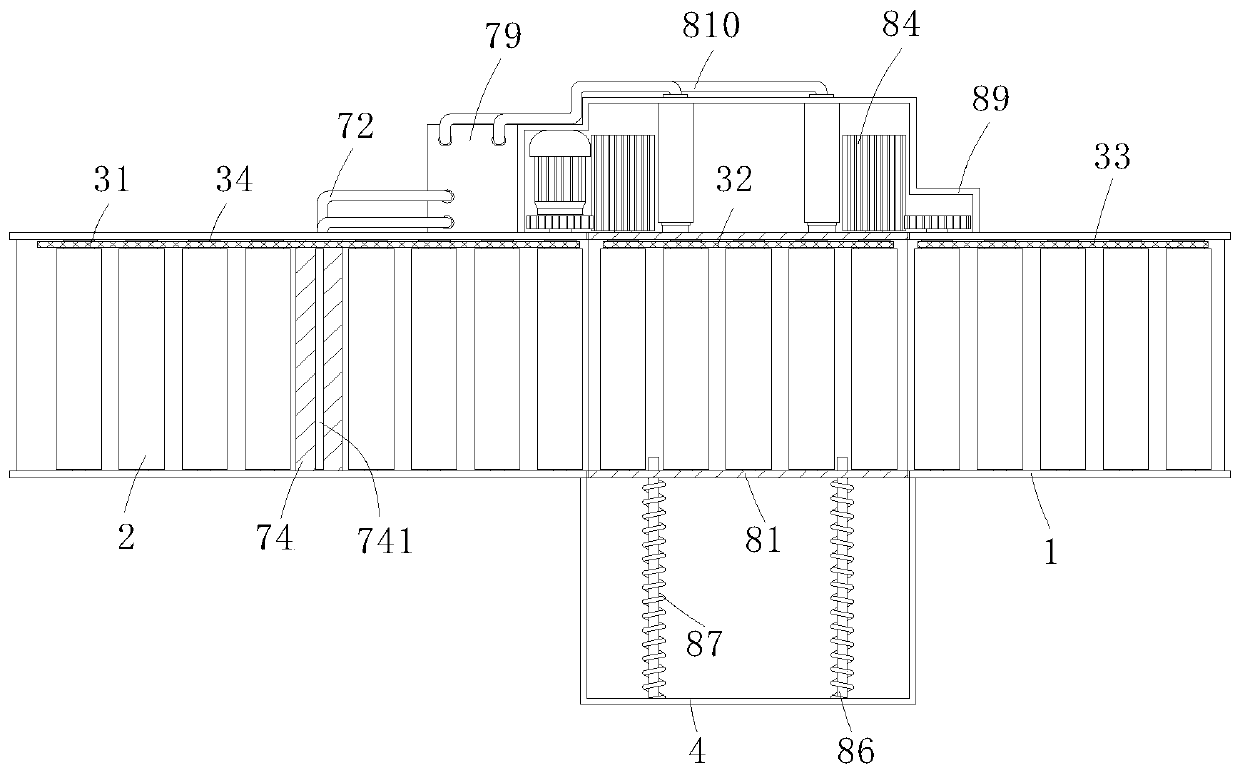

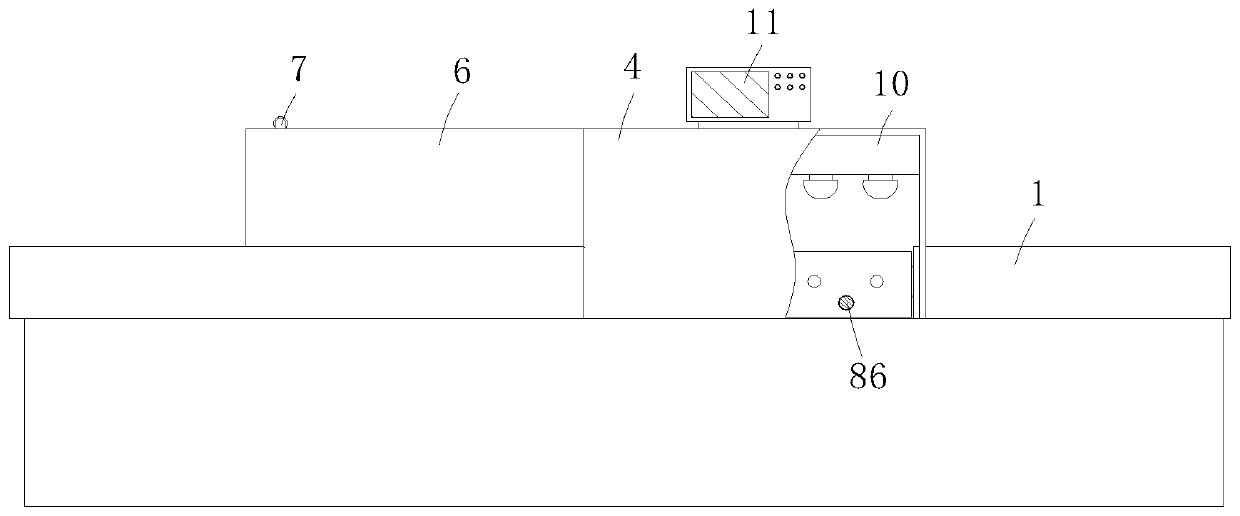

[0037]An automatic substrate processing equipment for circuit boards, comprising a bar-shaped transmission case 1 with an unclosed upper end, a plurality of transmission rollers 2 are horizontally installed in the inner cavity of the strip-shaped transmission case 1, and the plurality of transmission rollers 2 are A transmission belt assembly 3 is provided, and the transmission belt assembly 3 includes a transmission belt I31, a transmission belt II32 and a transmission belt III33 distributed sequentially from left to right along the moving direction of the substrate a, and the internal rotation of the transmission belt I31, the transmission belt II32 and the transmission belt III33 is installed with multiple a transmission pulley 34, and the transmission pulley 34 is matched and coaxially installed on the shaft end of the transmission roller 2, through the transmission mechanism of the transmission belt I31, the transmission belt II32 and the transmission belt III33 respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com