Wafer linear cutting slurry filtering device and cleaning control system thereof

A filter device and wire cutting technology, which is applied in the direction of filter circuit, filter separation, fixed filter element filter, etc., can solve the problems of mud dirt, abnormal disconnection, and reduced production efficiency, so as to avoid secondary adhesion and improve The effect of improving life and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

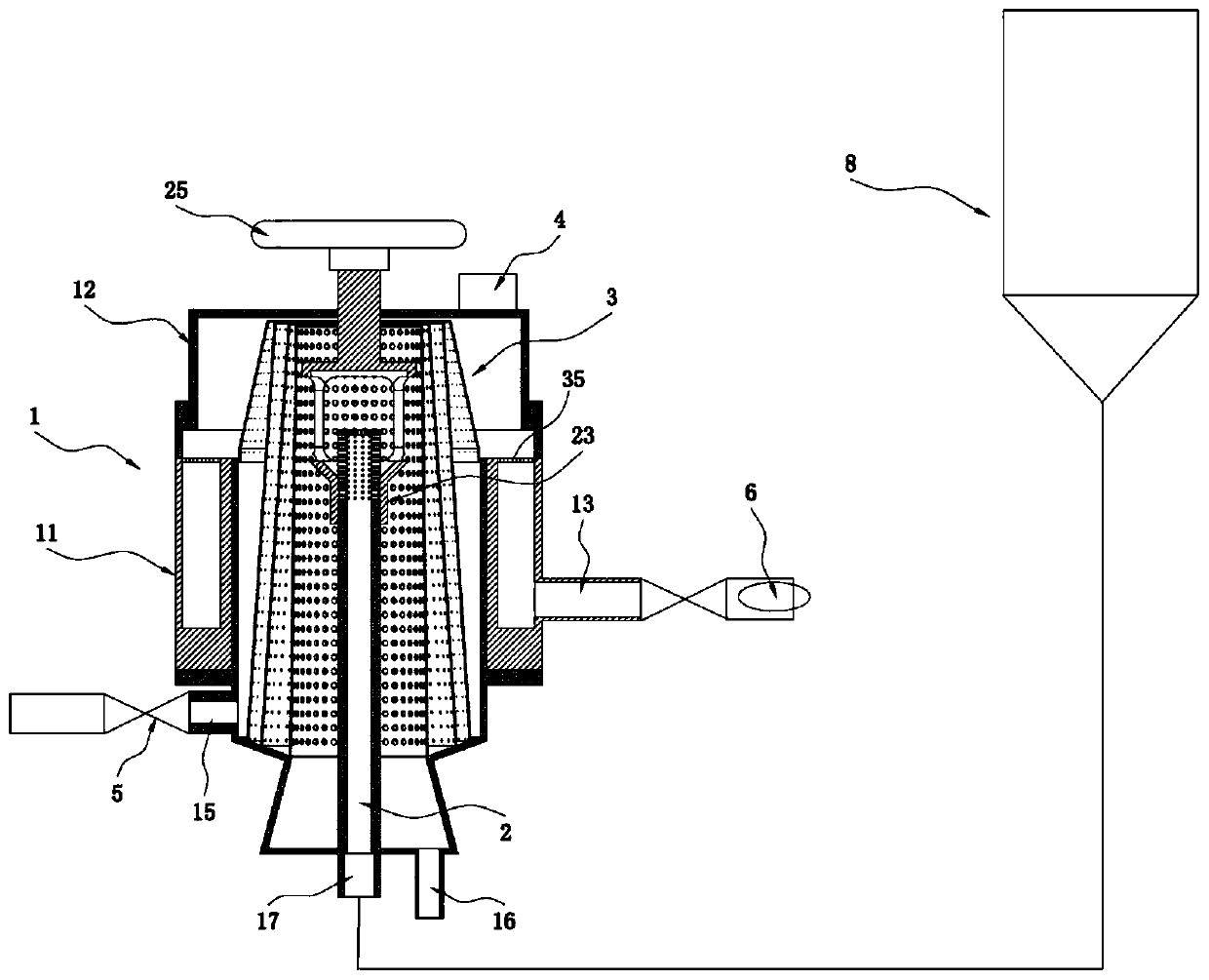

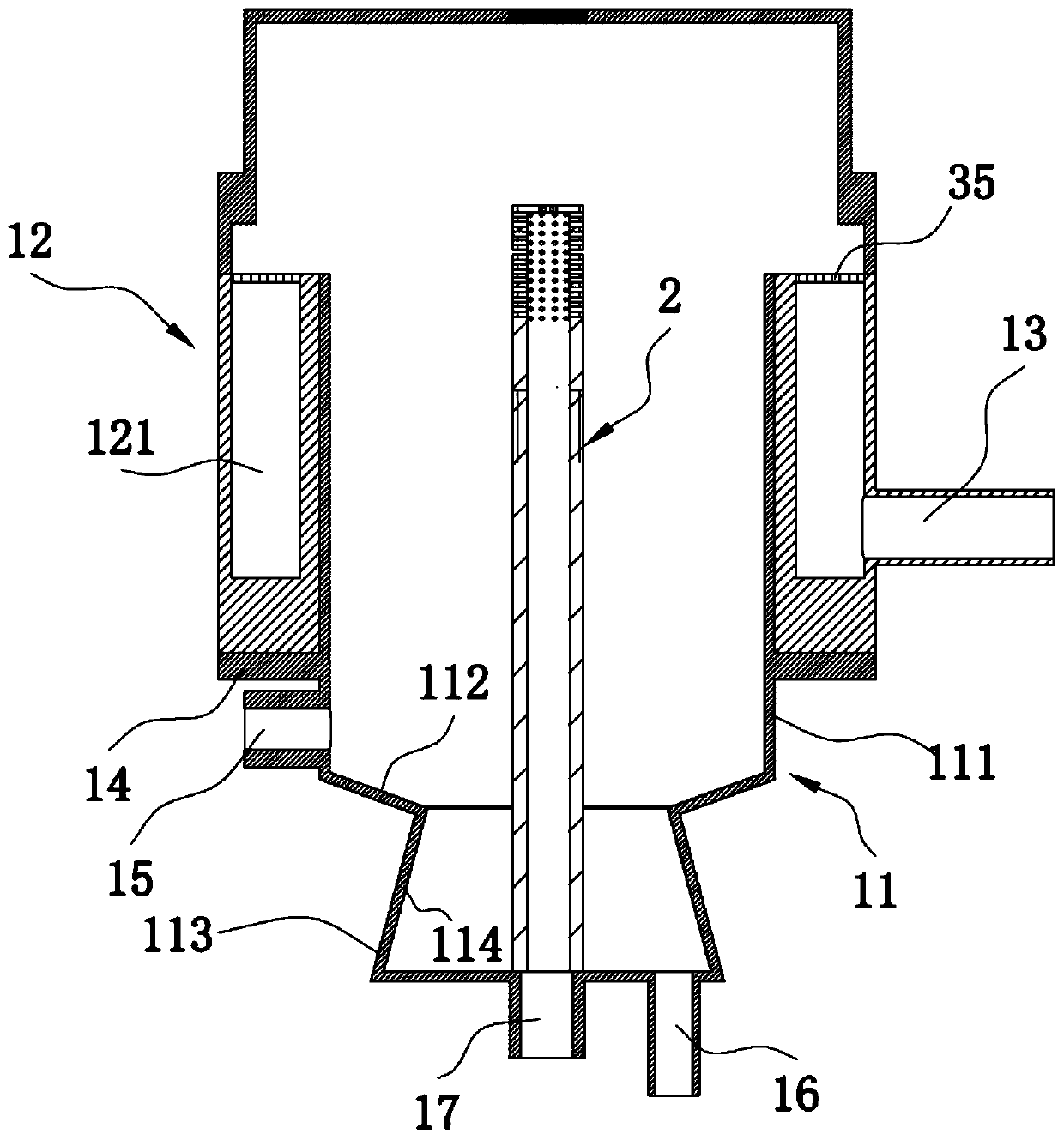

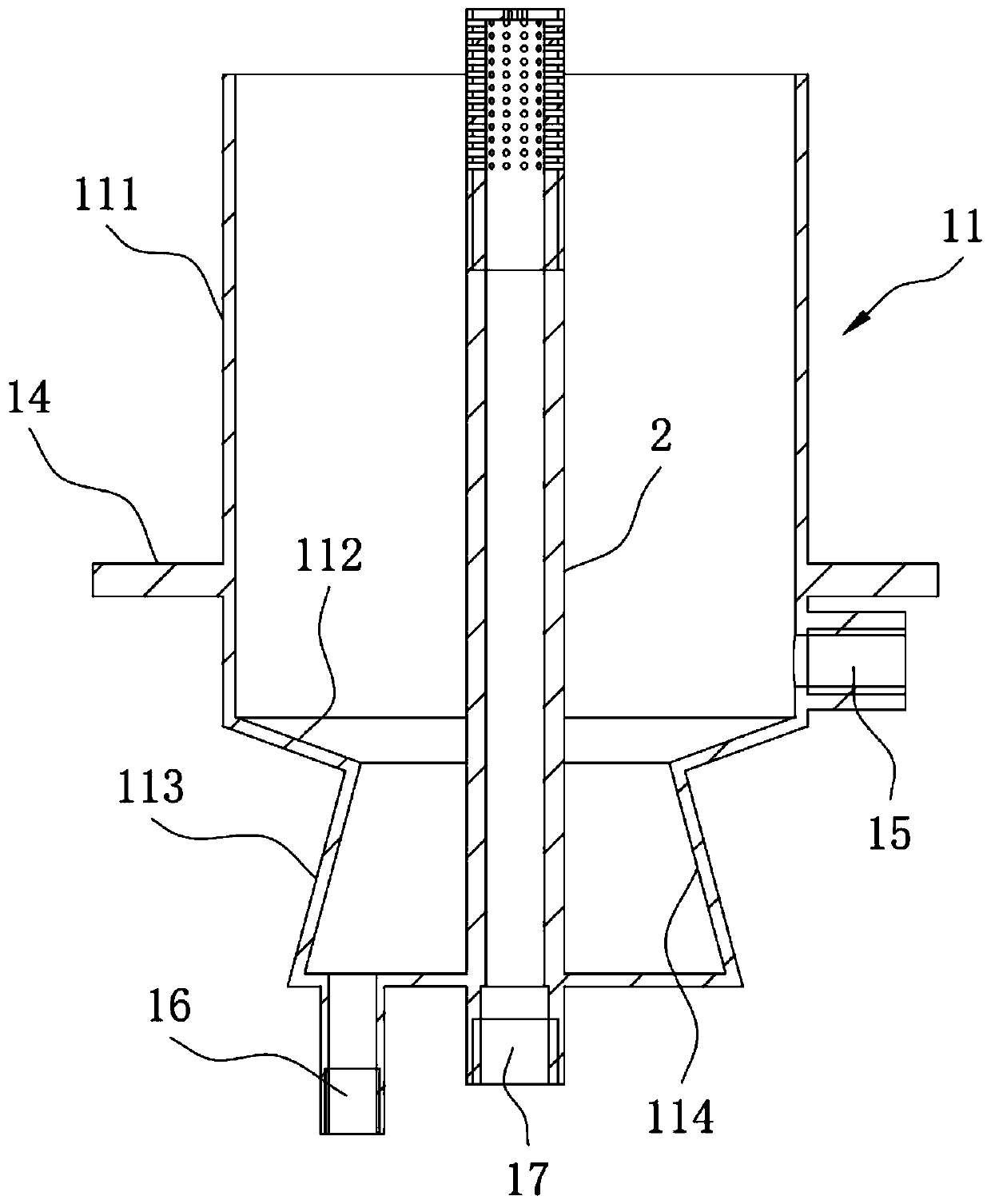

[0049] refer to Figure 1-Figure 7 , the present embodiment provides a wafer wire cutting mud filter device, comprising:

[0050] Sedimentation cylinder 1, used for settling mud debris, deposition cylinder 1 is provided with mud outlet 13;

[0051] The filter assembly 3 arranged in the deposition cylinder 1, the deposition cylinder 1 is separated by the filter assembly 3 to form an inner cavity and an outer cavity, and the mud outlet 13, the outer cavity and the inner cavity are connected in sequence, and the filter assembly 3 includes at least one layer of filter screen 31. The mesh surface of the net 31 is arranged obliquely with the vertical direction;

[0052] The j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com