Bristle-reinforced automatic mold sweeper

A reinforced, sweeping machine technology, applied in the direction of bristle brackets, cleaning methods using tools, brushes, etc., can solve the problems of the brush belt being fastened, the brush cannot be replaced, the brush belt falling off, etc., to eliminate Risk of falling off installation roller, easy production and maintenance, effect of saving quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

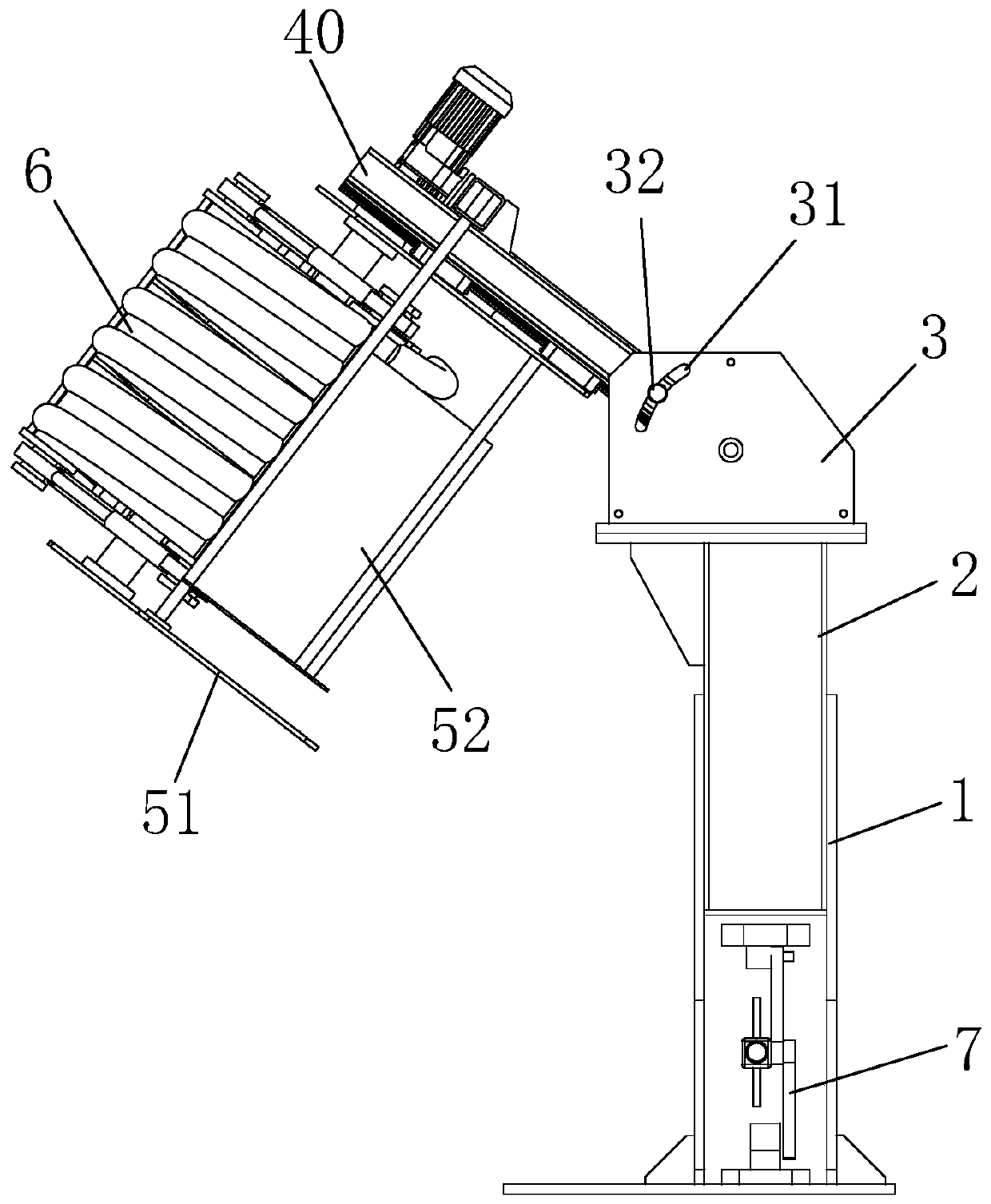

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

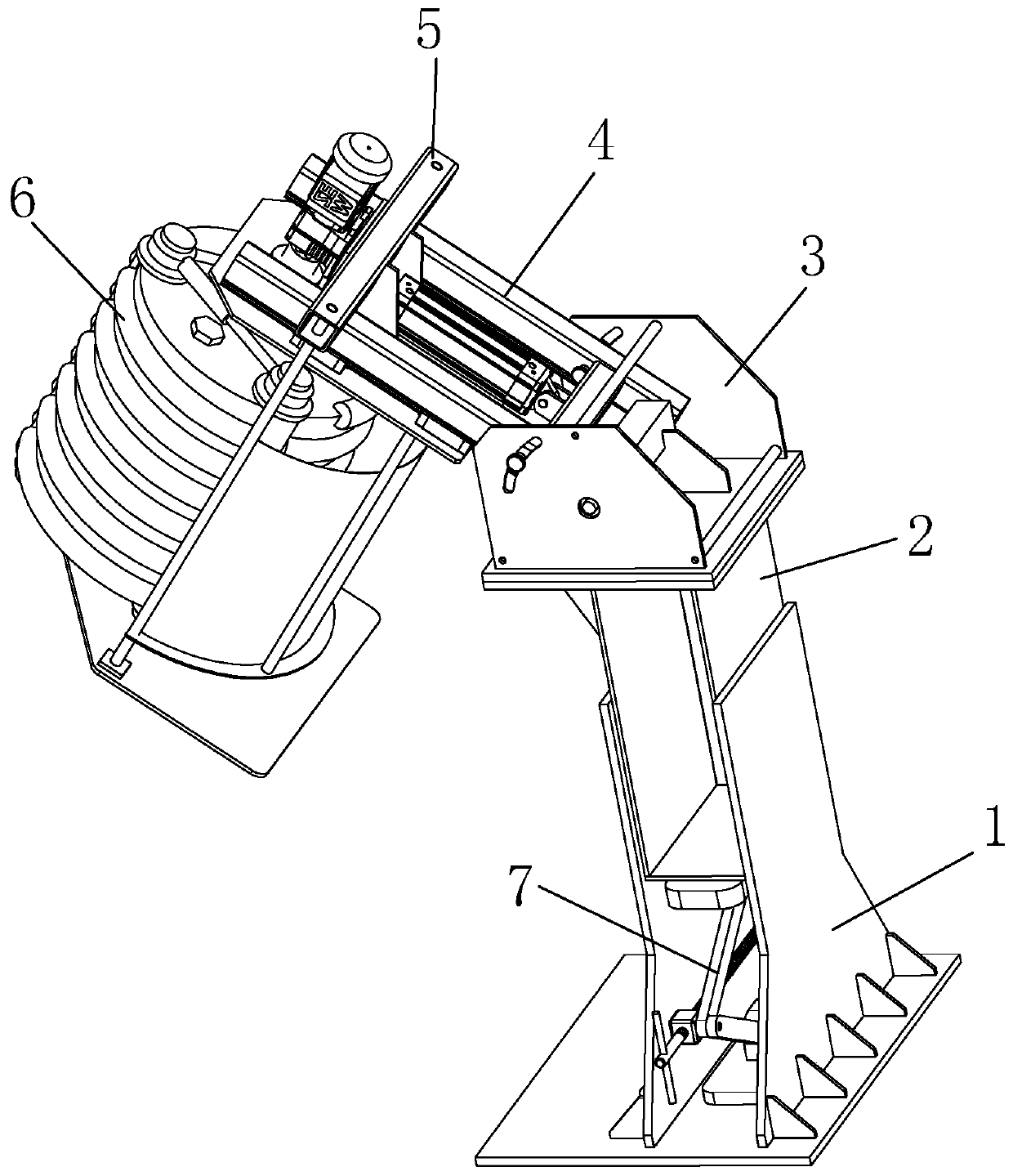

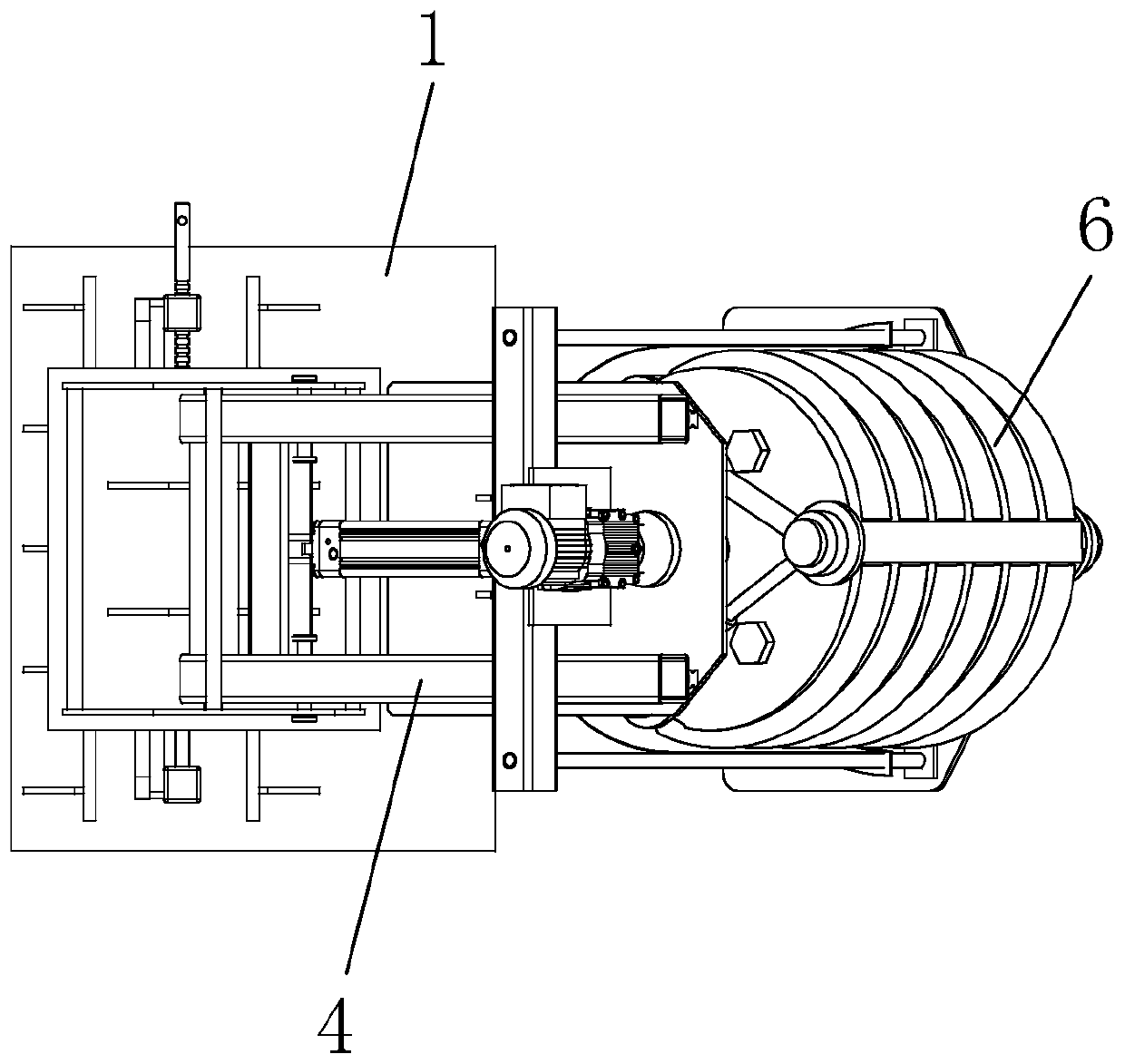

[0043] Such as Figure 1-3 The bristle-reinforced automatic mold cleaning machine shown includes a base 1, a sliding seat 2 and an installation seat 3, the sliding seat 2 can slide up and down relative to the base 1, wherein sliding wheels are provided on both sides of the sliding seat 2, and the base The inner side of the seat 1 is provided with a sliding groove, and the sliding wheels are rolled in the sliding groove to facilitate the sliding of the sliding seat 2 relative to the base 1, and the mounting seat 3 is fixed on the top of the sliding seat 2. The base 1, the sliding seat 2 Both the mounting base and the mounting base 3 are made of hard alloy steel to improve the support strength and prolong the service life. The base 1 includes a horizontally arranged base plate and two vertically distributed side plates, and a rib plate is provided between the base plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com