A kind of thermal shock resistant nizn ferrite material and preparation method thereof

A ferrite material and ferrite technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of unsatisfactory thermal shock, dark cracking phenomenon, etc., achieve low thermal expansion coefficient, and inhibit the expansion of cracks , The effect of improving thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Step 2, preparation of the ferrite main material.

[0047] Weigh raw material Fe according to formula 2 o 3 , NiO, ZnO, CuO, for later use; put the weighed main component raw materials into the sand mill, according to the material: ball: water mass ratio 1:4:1.5, add 1mm to 5mm in diameter into the sand mill tank Zirconia balls and deionized water, set the speed of the sand mill at 200-250rpm, and after ball milling for 4h-10h, the particle size of the powder is controlled at D50=1.0μm±0.2μm to prepare the slurry; put the slurry obtained in step 2 Dry in an oven, the oven temperature is set at 100°C-200°C, and the time is 10h-24h; then the powder is placed in a high-temperature sintering furnace for pre-sintering, the temperature is set at 830°C-880°C, and the heating curve is 1°C- 4°C / min, keep warm for 2h to 4h and then cool naturally to get calcined powder.

[0048] Step 3. Preparation of a NiZn heat-shock resistant material for large-scale ultra-thin products.

...

example 1

[0098] A thermal shock resistant NiZn ferrite material, its formula is divided into main component and additive component;

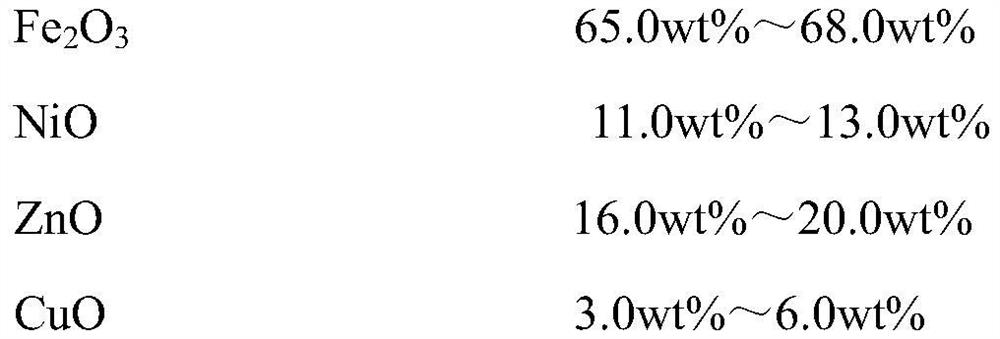

[0099] The main components are based on the weight of oxides:

[0100]

[0101] The additive is special glass powder, accounting for the weight of the main material:

[0102] Glass powder 0.5%

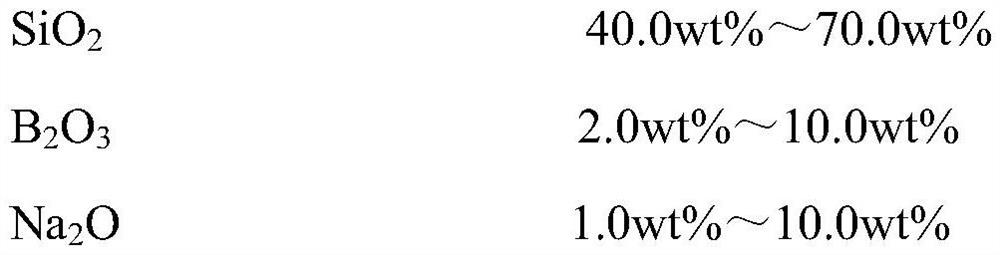

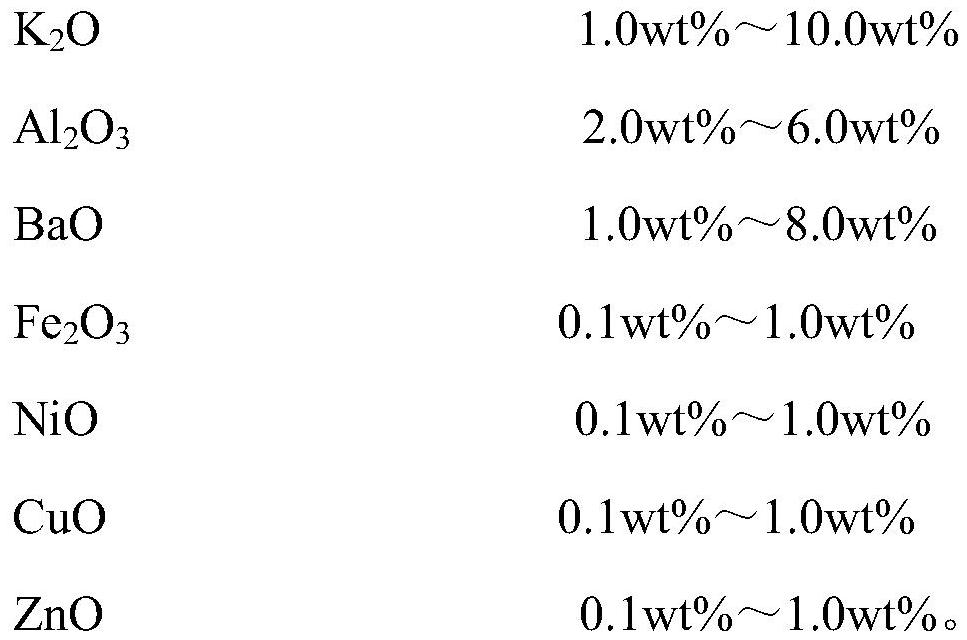

[0103] The main composition of glass powder is SiO 2 , B 2 o 3 、Na 2 O, K 2 O, Al 2 o 3 , BaO, Fe 2 o 3 , NiO, CuO, ZnO, the composition of which is based on the weight percentage of the total glass powder,

[0104]

[0105]

[0106] The main components of raw materials and additive components are high-purity raw materials, and the purity is Fe 2 o 3 ≥99.5wt%, NiO≥99.5wt%, ZnO≥99.5wt%, CuO≥99.5wt%, SiO 2 ≥99wt%, B 2 o 3 ≥99wt%, Na 2 O≥99wt%, K 2 O≥99wt%, Al 2 o 3 ≥99wt%, BaO≥99wt%.

[0107] A kind of manufacturing method of heat-shock resistant NiZn ferrite material for large-scale ultra-thin product, comprises the following steps:

...

example 2

[0137] A thermal shock resistant NiZn ferrite material, its formula is divided into main component and additive component;

[0138] The main components are based on the weight of oxides:

[0139]

[0140] The additive is special glass powder, accounting for the weight of the main material:

[0141] Glass powder 0.6%

[0142] The main composition of glass powder is SiO 2 , B 2 o 3 、Na 2 O, K 2 O, Al 2 o 3 , BaO, Fe 2 o 3 , NiO, CuO, ZnO, the composition of which is based on the weight percentage of the total glass powder,

[0143]

[0144] The main components of raw materials and additive components are high-purity raw materials, and the purity is Fe 2 o 3 ≥99.5wt%, NiO≥99.5wt%, ZnO≥99.5wt%, CuO≥99.5wt%, SiO 2 ≥99wt%, B 2 o 3 ≥99wt%, Na 2 O≥99wt%, K 2 O≥99wt%, Al 2 o 3 ≥99wt%, BaO≥99wt%.

[0145] A kind of manufacturing method of heat-shock resistant NiZn ferrite material for large-scale ultra-thin product, comprises the following steps:

[0146] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com