Non-woven fabric material and preparation method and application thereof

A technology of non-woven fabric and grafting reaction, which is applied in the field of non-woven fabric materials and preparation of non-woven fabric materials, which can solve the problems of unfavorable pollutant diffusion, narrow space in the car, and poor air circulation, so as to improve the air quality in the car , low cost, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

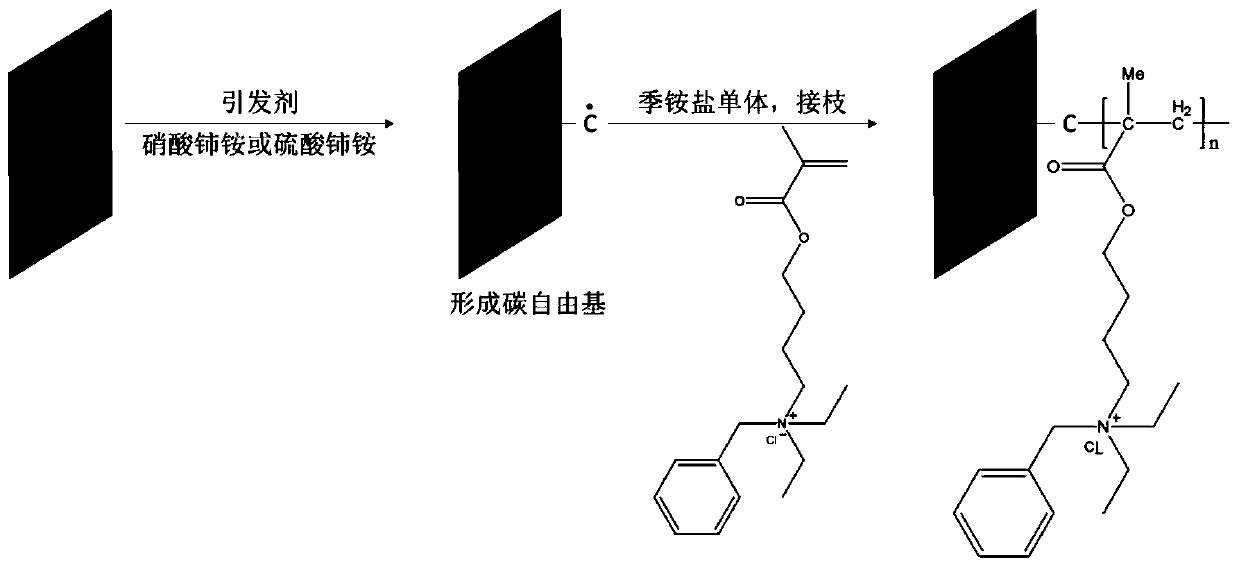

[0057] The invention provides a grafted quaternary ammonium salt non-woven fabric material for an air-conditioning filter element for vehicles and a preparation method thereof, which is characterized in that the surface of the non-woven fabric for an air-conditioning filter element is modified by redox grafting, and the grafted quaternary ammonium Salt monomer forms graft layer, comprises the following steps:

[0058] (1) Add the quaternary ammonium salt monomer material in deionized water and stir evenly, so that the molar concentration of the quaternary ammonium salt monomer is 0.6mol / L, which is defined as solution A;

[0059] (2) add ceric ammonium nitrate initiator in solution A, make ceric ammonium nitrate initiator molar concentration be 0.02mol / L, be defined as solution B;

[0060] (3) Put an area of 100cm in solution B 2 Polypropylene (PP) filter cloth (gram weight 135g / m 2 ) and stir, so that the mass ratio of non-woven fabric and solution B is 1:20, which is def...

Embodiment 2

[0065] The invention provides a grafted quaternary ammonium salt non-woven fabric material for an air-conditioning filter element for vehicles and a preparation method thereof, which is characterized in that the surface of the non-woven fabric for an air-conditioning filter element is modified by redox grafting, and the grafted quaternary ammonium Salt monomer forms graft layer, comprises the following steps:

[0066] (1) Add the quaternary ammonium salt monomer material in deionized water and stir evenly, so that the molar concentration of the quaternary ammonium salt monomer is 1.0mol / L, which is defined as solution A;

[0067] (2) add ceric ammonium sulfate initiator in solution A, make ceric ammonium sulfate initiator molar concentration be 0.04mol / L, be defined as solution B;

[0068] (3) Put an area of 100cm in solution B 2 Polypropylene (PP) filter cloth (gram weight 135g / m 2 ) and stir so that the mass ratio of non-woven fabric and solution B is 1:60, which is defi...

Embodiment 3

[0073] The invention provides a grafted quaternary ammonium salt non-woven fabric material for an air-conditioning filter element for vehicles and a preparation method thereof, which is characterized in that the surface of the non-woven fabric for an air-conditioning filter element is modified by redox grafting, and the grafted quaternary ammonium Salt monomer forms graft layer, comprises the following steps:

[0074] (1) Add the quaternary ammonium salt monomer material in deionized water and stir evenly, so that the molar concentration of the quaternary ammonium salt monomer is 1.4mol / L, which is defined as solution A;

[0075] (2) add ceric ammonium sulfate initiator in solution A, make ceric ammonium sulfate initiator molar concentration be 0.05mol / L, be defined as solution B;

[0076] (3) Put an area of 100cm in solution B 2 Polypropylene (PP) filter cloth (gram weight 110g / m 2 ) and stir, so that the mass ratio of non-woven fabric and solution B is 1:100, which is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com