Non-woven material and preparation method and application thereof

A non-woven fabric and graft reaction technology, applied in the field of materials, can solve the problems of unfavorable pollutant diffusion, poor air circulation, narrow interior space, etc., and achieve a simple and easy preparation method, improve service life, and expand the scope of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

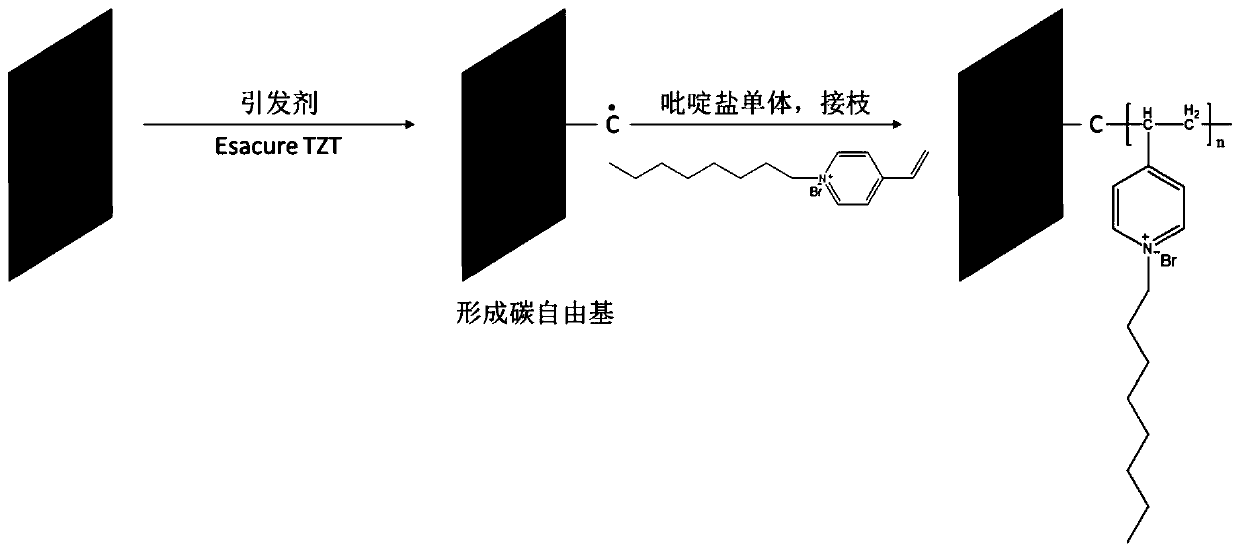

[0061] The present invention provides a grafted pyridinium salt non-woven material for vehicle air-conditioning filters and a preparation method thereof, which is characterized in that the surface of the non-woven fabric for air-conditioning filters is modified by oxidation-reduction grafting, and the grafted pyridinium salt Body forms graft layer, comprises the following steps:

[0062] (1) Add 4-vinylpyridine-octylammonium bromide pyridinium salt monomer material into deionized water and stir evenly, so that the molar concentration of pyridinium salt monomer is 0.5mol / L, which is defined as solution A;

[0063] (2) Add Esacure TZT photoinitiator in solution A, make the mass percent concentration of photoinitiator be 0.1%, be defined as solution B;

[0064] (3) Put an area of 100cm in solution B 2 PP non-woven material (gram weight 120g / m 2 ) and stir, so that the mass ratio of non-woven fabric and solution B is 1:20, which is defined as mixture C;

[0065] (4) Fill the ...

Embodiment 2

[0069] The invention provides a grafted pyridinium salt non-woven fabric material for vehicle air-conditioning filters and a preparation method thereof, which is characterized in that the surface of the non-woven fabric for air-conditioning filters is grafted and modified by ultraviolet light irradiation, and the grafted pyridine Salt monomer forms graft layer, comprises the following steps:

[0070] (1) Add 4-vinylpyridine-octylammonium bromide pyridinium salt monomer material into deionized water and stir evenly, so that the molar concentration of pyridinium salt monomer is 1.0mol / L, which is defined as solution A;

[0071] (2) Add Esacure TZT photoinitiator in solution A, make the mass percentage concentration of photoinitiator be 0.5%, be defined as solution B;

[0072] (3) Put an area of 100cm in solution B 2 PET non-woven material (gram weight 150g / m 2 ) and stir, so that the mass ratio of non-woven fabric and solution B is 1:100, which is defined as mixture C;

[0...

Embodiment 3

[0077] The invention provides a grafted pyridinium salt non-woven fabric material for vehicle air-conditioning filters and a preparation method thereof, which is characterized in that the surface of the non-woven fabric for air-conditioning filters is grafted and modified by ultraviolet light irradiation, and the grafted pyridine Salt monomer forms graft layer, comprises the following steps:

[0078] (1) Add 4-vinylpyridine-octylammonium bromide pyridinium salt monomer material into deionized water and stir evenly, so that the molar concentration of pyridinium salt monomer is 1.0mol / L, which is defined as solution A;

[0079] (2) Add Esacure TZT photoinitiator in solution A, make the mass percentage concentration of photoinitiator be 0.5%, be defined as solution B;

[0080] (3) Put an area of 100cm in solution B 2 PET non-woven material (gram weight 180g / m 2 ) and stir, so that the mass ratio of non-woven fabric and solution B is 1:100, which is defined as mixture C;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com