Pouring method of high and large concrete frame column

A concrete column and concrete technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems that affect the construction efficiency and cost, and the rotten roots of concrete frame columns, so as to ensure the construction quality, ensure the strength and supporting capacity, and prevent holes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

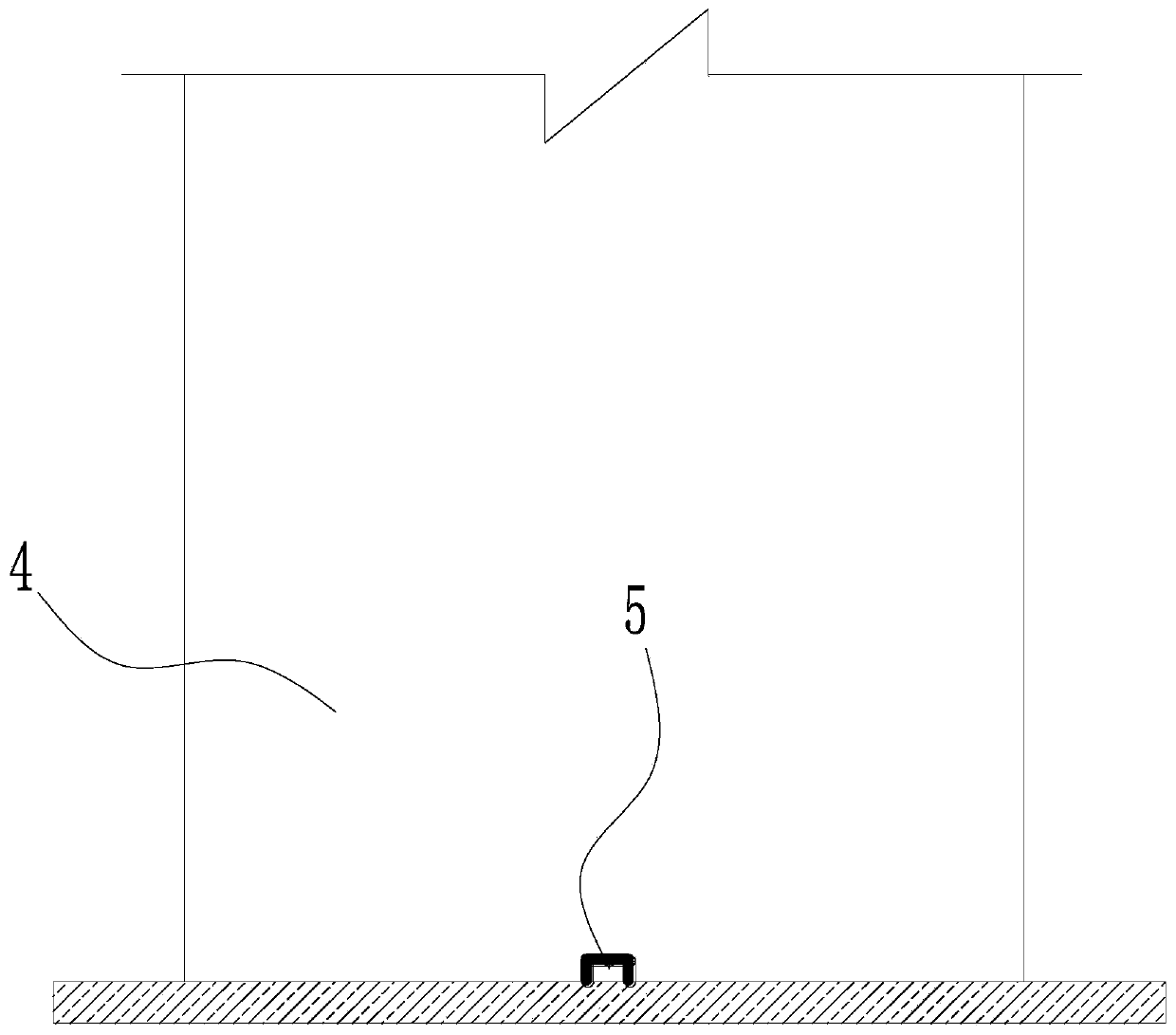

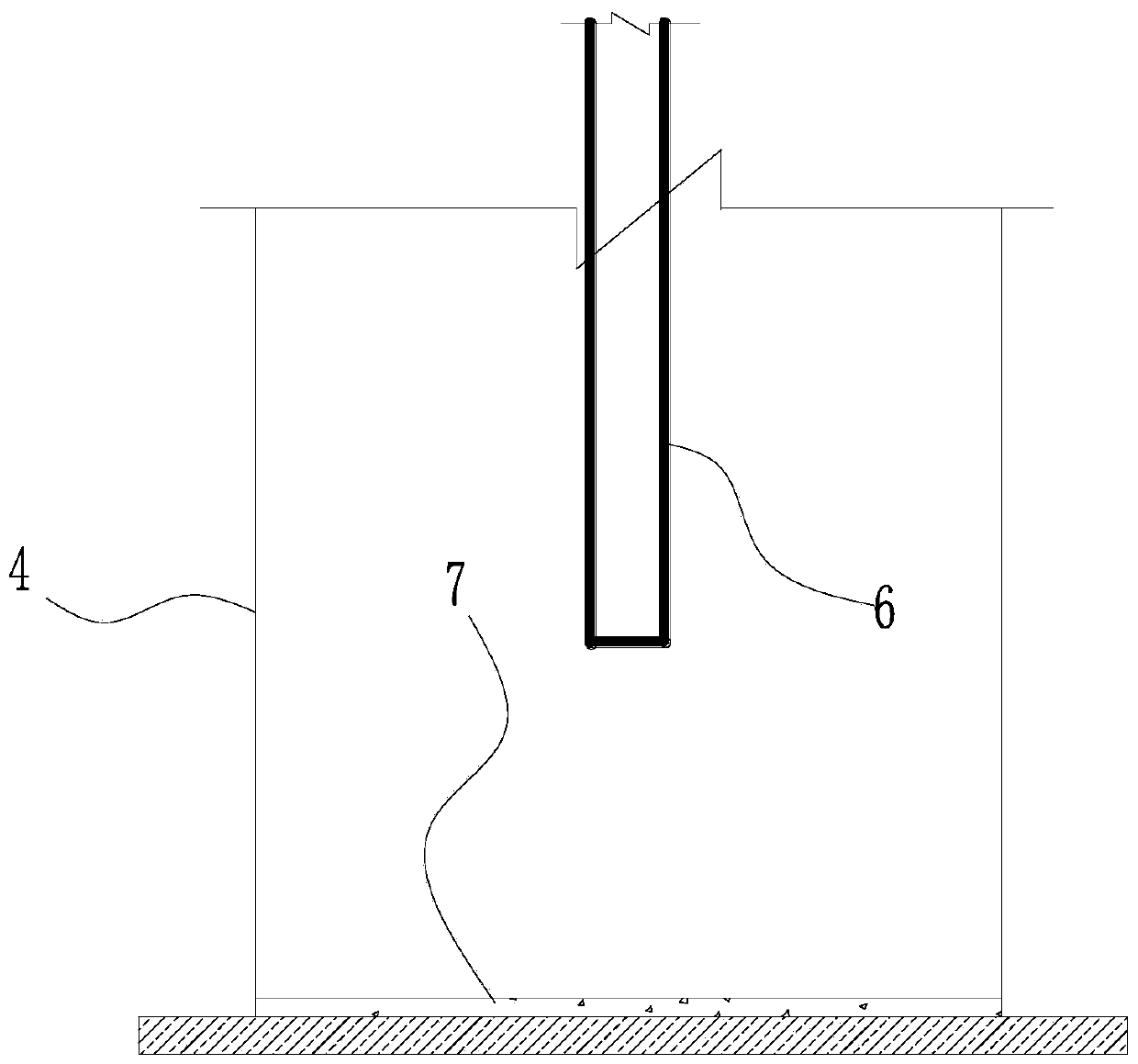

[0028] When using the existing conventional construction technology, there are a large number of concrete frame columns with rotten roots. The applicant carefully studied the reasons for the rotten roots and found that most of the concrete frame columns with rotten roots existed in the pouring cavity before pouring. A small amount of stagnant water, stagnant water is produced during the wetting process, and wetting refers to watering the inside of the formwork and the steel bars, so as to keep the inside of the formwork and the steel bars in a wet state, so as to prevent the formwork and steel bars from absorbing water when pouring concrete. The existing formwork encloses a sealed pouring cavity, and excess water flows to the bottom of the pouring cavity and generates accumulated water, which causes rotten roots of the concrete frame columns after pouring, affecting the load-bearing capacity. In response to this phenomenon, the applicant made improvements to the prior art.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com