Small hydraulic ash removal device

A hydraulic ash removal and hydraulic technology, which is applied in the field of ash removal from the combustion chamber, can solve the problems of limited installation area of hydraulic soot blowers, low-load fire extinguishing of boilers, jamming of equipment transmission, etc., to achieve easy installation at any time and uniform water flow , layout flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A small-sized hydraulic hydraulic ash removal device includes a spray gun body, which includes a gun body 1 , an outer cylinder body 4 and a water inlet pipe 5 .

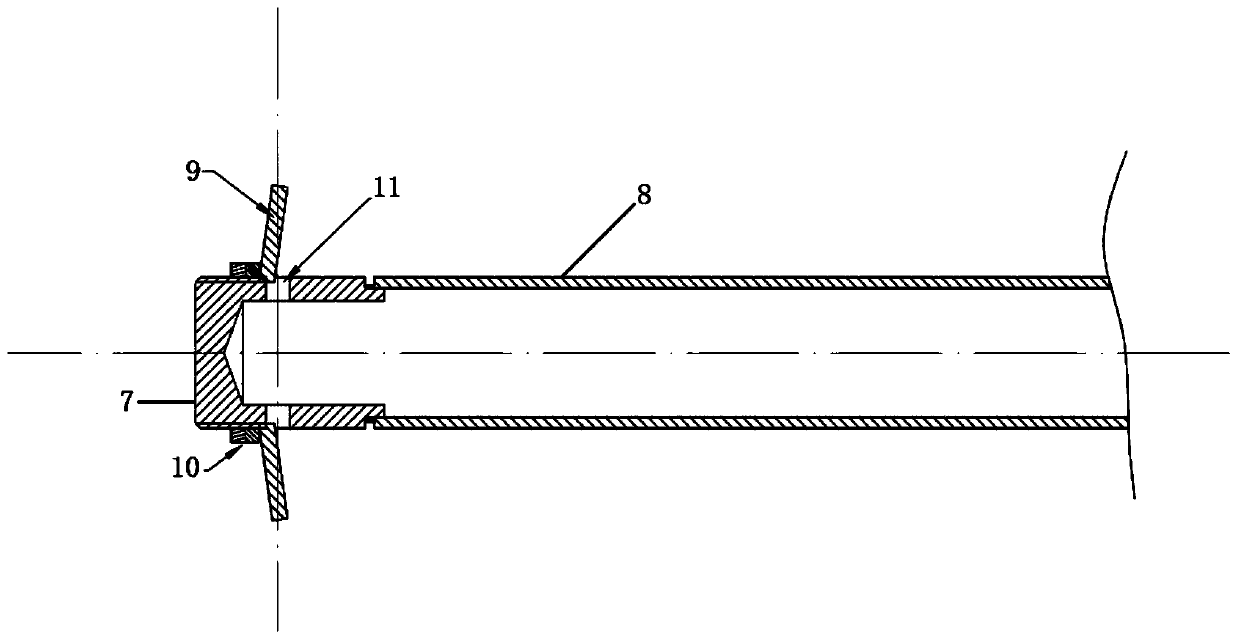

[0032] Such as figure 1 As shown, the gun body 1 includes a gun head 7, a gun barrel 8 and an annular deflector 9, the gun head 7 is threadedly connected with the gun barrel 8, the gun head 7 is provided with a nozzle 11, and the annular guide vane 9 is arranged through a threaded connection Above the nozzle 11, the annular deflector 9 is used to control the angle of the water sprayed from the nozzle 11, and the back side of the annular deflector 9 is provided with

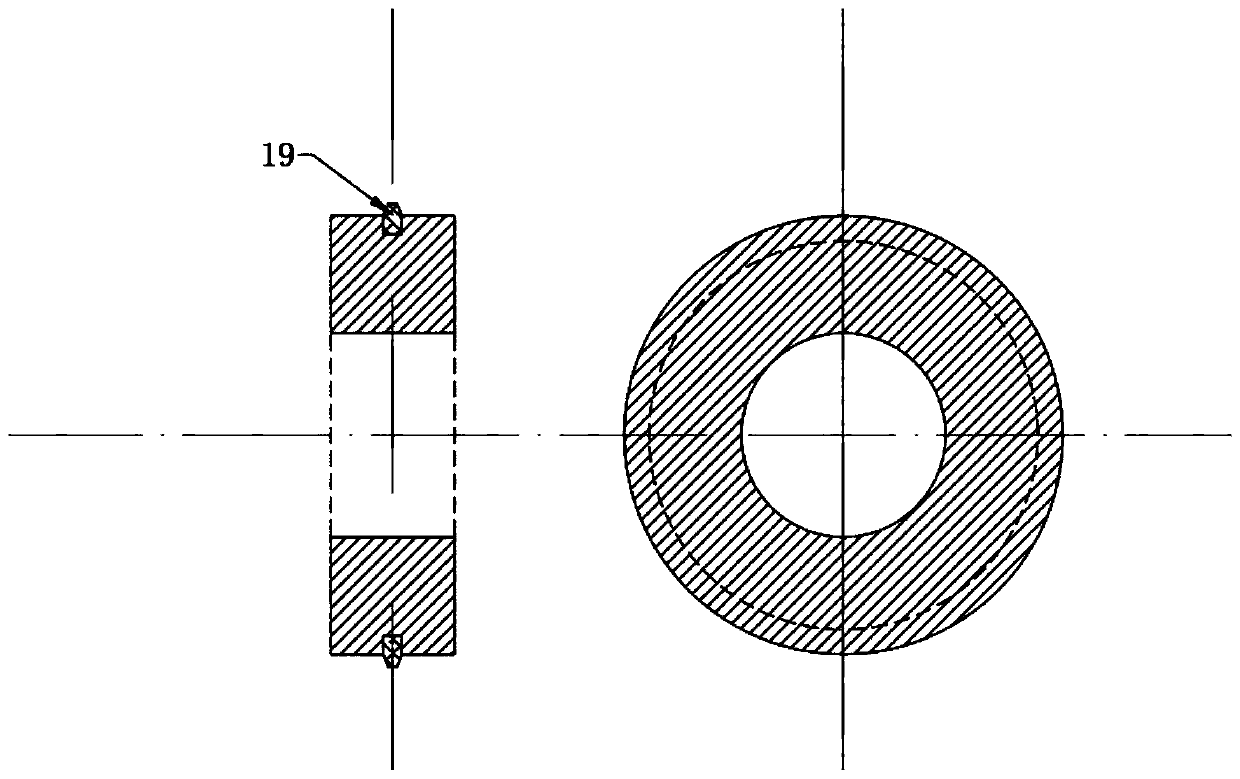

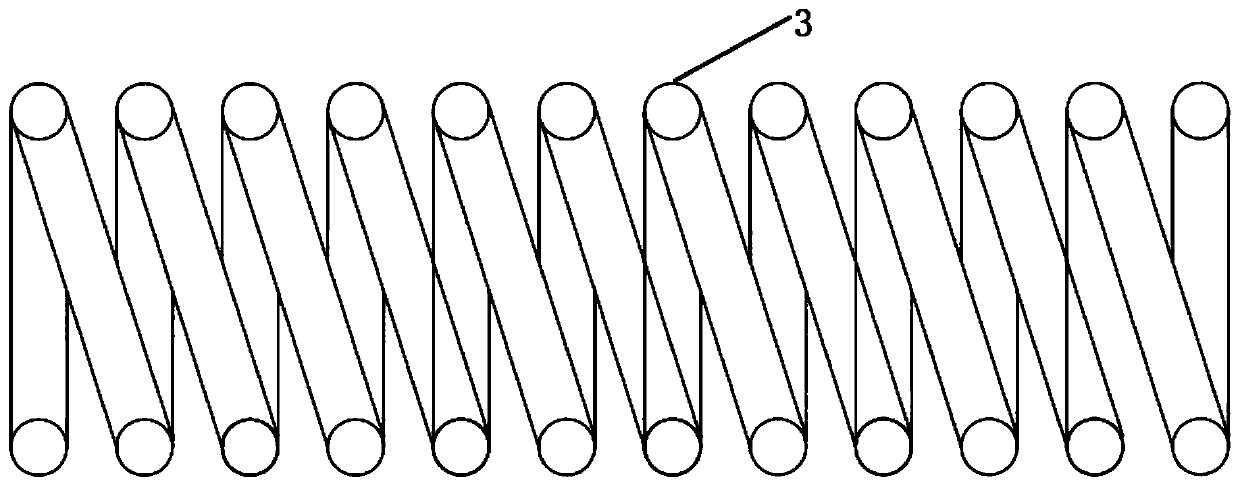

[0033] Such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, the outer cylinder 4 includes a cylinder 12, a mounting flange 2 and a diameter flange 13, one end of the cylinder 12 is welded to the installation flange 2, and the other end of the cylinder is welded to the diameter flange 13; A compression spring 3 is arranged inside,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com