Failure analysis method for solid tantalum electrolytic capacitor with built-in fuse

A technology of tantalum electrolytic capacitors and failure analysis, which is applied in the field of failure analysis of solid tantalum electrolytic capacitors with built-in fuses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] This embodiment is a failure analysis method for a solid tantalum electrolytic capacitor with a built-in fuse. The failure analysis method includes the following steps:

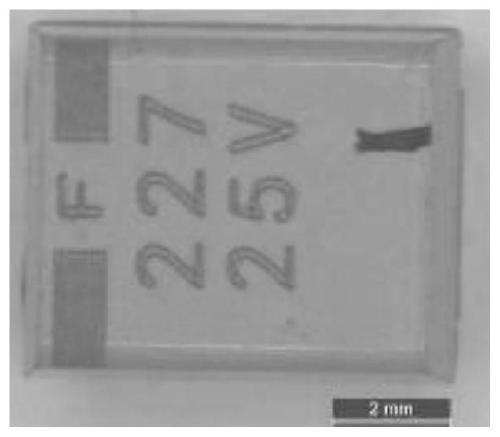

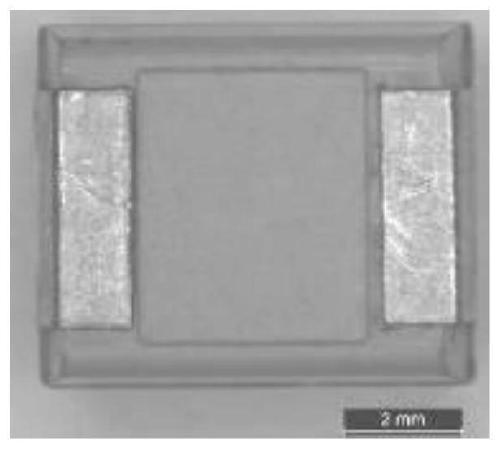

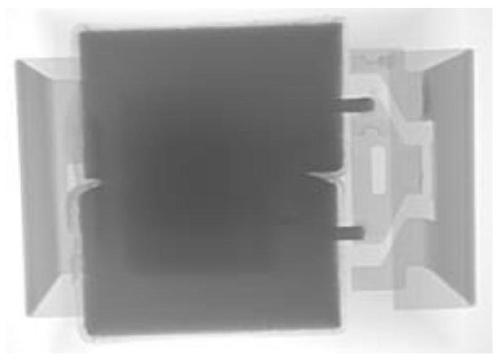

[0065] Such as figure 1 , figure 2 , image 3 As shown, observe the appearance and morphology of solid tantalum electrolytic capacitors, and observe the internal structure of solid tantalum electrolytic capacitors by ray. figure 1 , figure 2 , image 3 The location of the fuse can be determined as image 3 In the A area, by image 3 It can be seen that there is a fuse on the anode side of the solid tantalum electrolytic capacitor, and the fuse is connected to the metal frame through solder, and the solder on the other side is uneven;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com