Pole piece and preparation method thereof and application of pole piece in battery

A pole piece, conductive agent technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of decreased utilization of electrode active materials, limited lithium ion diffusion kinetics, damaged battery energy density, etc. The effect of increasing rate performance and cycle stability, reducing labor costs, and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] A kind of preparation of negative pole sheet:

[0117] (1) Preparation of the first electrode slurry with a viscosity of 4000mPa·s and a solid content of 52wt%:

[0118] (a) Mix the first thickener (CMC2200) and the first solvent (water) to obtain the mixed material 1;

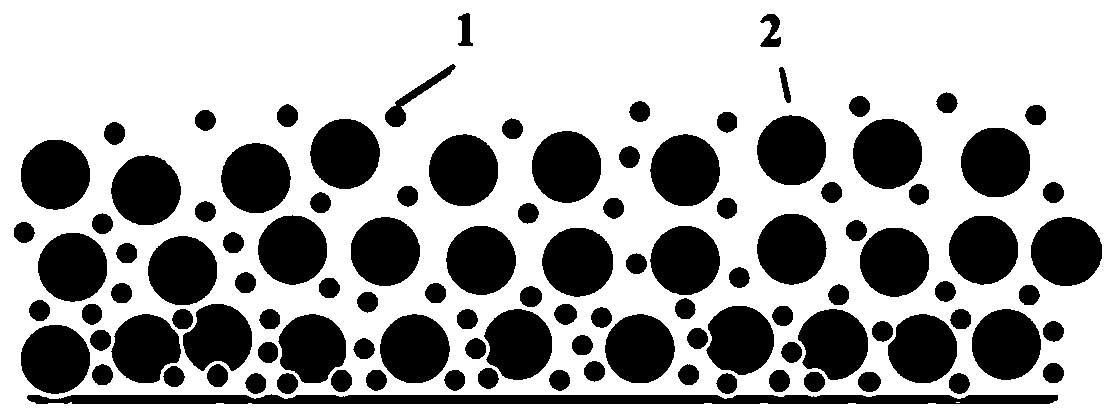

[0119] (b) mixing the first active material (artificial graphite) and the first conductive agent (Li435) to obtain a mixed material 2;

[0120] (c) stirring and mixing the mixed material 2 and part of the mixed material 1, the stirring speed is 2500 rpm, and the stirring time is 60 min, to obtain the mixed material 3, the solid content of the mixed material 3 is 65wt%;

[0121] (d) mixing the remaining mixed material 1 with mixed material 3 to obtain mixed material 4;

[0122] (e) Stir and mix the mixed material 4 and the first binder (SBR451B), the stirring rate is 1500rpm, and the stirring time is 60min to obtain the first electrode slurry, which is carried out by using a 150-mesh stainless steel me...

Embodiment 2

[0134] The difference from Example 1 is that the first conductive agent in step (b) is SP, that is, the first conductive agent is the same as the second conductive agent.

Embodiment 3

[0136] The difference with Example 1 is that, in the first electrode slurry described in step (1), the content of the first conductive agent is 1.1wt%; in the second electrode slurry described in step (2), the content of the second conductive agent The content is 0.9wt% (the total amount of the conductive agent in the overall pole piece remains unchanged, and the increase or decrease of the conductive agent in the slurry is equally shared by other components).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com