Method for preparing bimetal-organic framework/bismuth vanadate composite photoanode material

An organic framework and photoanode technology, applied in the field of BiVO4-based composite materials, can solve the problems of easy recombination, slow photo-generated carrier migration rate, and low photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

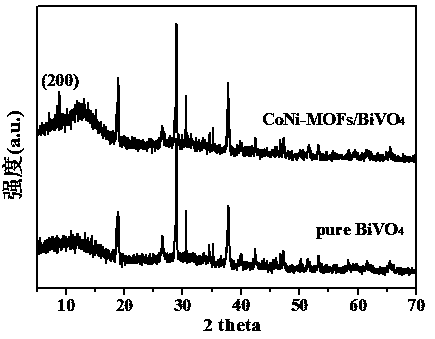

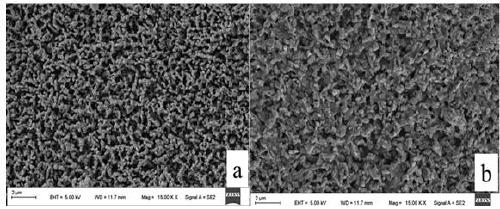

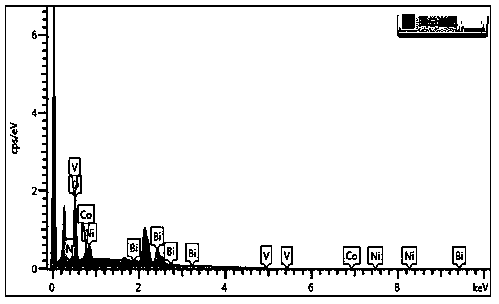

[0032] Below through specific embodiment CoNi-MOFs / BiVO of the present invention 4 The preparation and properties are further explained.

[0033] 1. Preparation of BiVO4 photoanode

[0034] According to the method of electrodeposition combined with heat treatment by Kim and Choi's group, porous BiVO 4 The membrane was successfully prepared. Steps: First, BiOI nanosheets were prepared by electrodeposition using CHI 660D electrochemical workstation. FTO glass cleaned ultrasonically with acetone / isopropanol / distilled water (volume ratio: 1:1:1) was used as the working electrode, the Ag / AgCl (3.5 M KCl) electrode was used as the reference electrode, and the Pt electrode was used as the counter electrode. with 6M HNO 3 Adjust the pH of 50 mL0.4 M KI solution to 1.5~1.7, then add 0.970 g Bi(NO 3 ) 3 • 5H 2 O until dissolved and the solution color changed to orange-red. Then slowly add 20ml 0.498 g 1,4-benzoquinone ethanol solution dropwise and stir for several minutes, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com