Positive electrode piece having concentration gradient and preparation method thereof

A positive pole piece and concentration gradient technology, which is applied in the field of positive pole piece with concentration gradient and its preparation, can solve the problem of unsolved performance deterioration, unimproved contact between current collector and active material, large internal resistance, reduction of positive electrode material gram capacity, etc. problems, to achieve the effect of providing thermal stability and cycle performance, improving cell gas production, and reducing charge transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

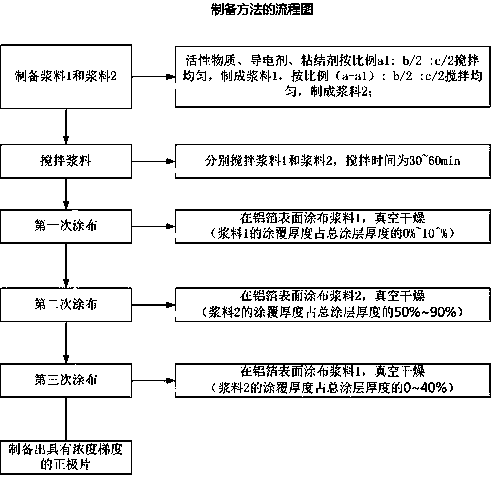

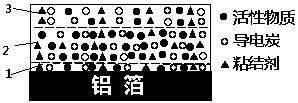

[0028] In order to make the technical solutions and beneficial effects of the present invention easier to understand, the following will be described in detail in conjunction with the accompanying drawings and specific embodiments, as figure 1 Shown is the preparation flow chart, figure 2 is a schematic diagram of a positive electrode sheet with a concentration gradient,

[0029] 1. Take 4kg of active material (NCM811), 1kg of conductive carbon black, 1kg of binder (PVDF) and fully stir and disperse in a mixing tank to prepare slurry 1. Take 14kg of active material (NCM811), 1kg of conductive carbon black, viscous Binder (PVDF) 1kg was fully stirred and dispersed in another stirring tank to prepare slurry 2,

[0030] 2. In an environment with a relative humidity of 1%, transfer slurry 1 and slurry 2 to storage tanks and stir for 60 minutes at a speed of 350rmp;

[0031] 3. Coat the slurry 1 on the aluminum foil, control the coating thickness to account for 10% of the total ...

Embodiment 2

[0036] 1. Take 6kg of active material (NCM811), 1kg of conductive carbon black, 1kg of binder (PVDF) and fully stir and disperse in a mixing tank to prepare slurry 1. Take 12kg of active material (NCM811), 1kg of conductive carbon black, viscous Binder (PVDF) 1kg was fully stirred and dispersed in another stirring tank to prepare slurry 2,

[0037] 2. According to the same method as in Example 1, a positive electrode sheet with a concentration gradient is prepared,

[0038] After rolling, slitting, and die-cutting, the prepared positive electrode sheet was assembled into a pouch battery. The negative electrode was made of graphite, and the electrolyte was an EC / PC / DEC system containing LiPF6 (1mol / L). Table 1 shows the test structure of the capacity retention rate and cycle DCR growth (voltage range 2.8~4.3V) of 1C charge-discharge cycle at room temperature for 1000 cycles, and the discharge performance at 2C and 3C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com